Mildew-proof and fresh-keeping paperboard and preparation method thereof

A kind of cardboard and anti-mildew technology, used in paper, papermaking, paper coating and other directions, can solve the problems of uneven surface of the substrate, large pores, coating breakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

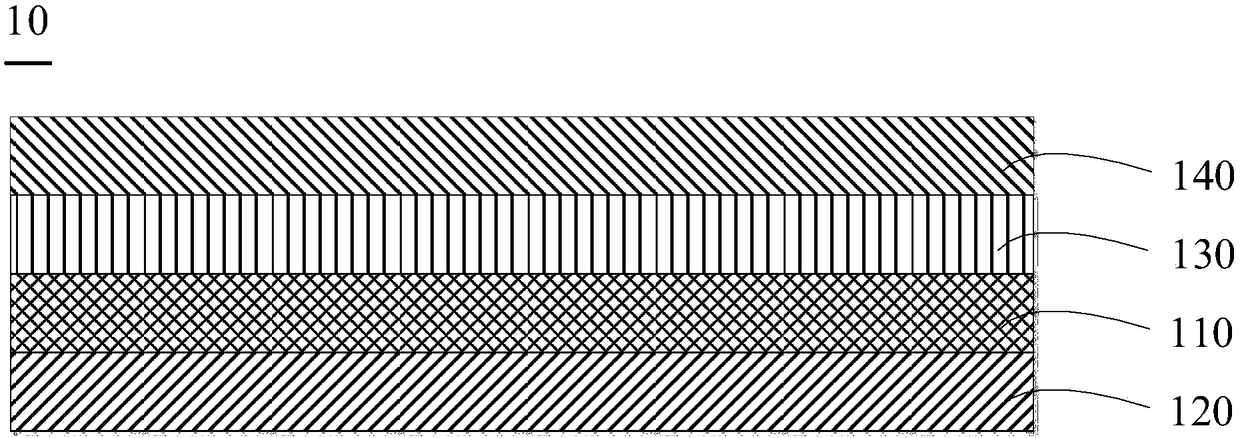

[0039] The present invention also provides a method for preparing the above-mentioned mildew-proof and fresh-keeping cardboard in an embodiment, comprising the following steps:

[0040] Step S1: Mix the raw materials of the barrier coating to prepare a barrier coating; mix the raw materials of the anti-mold and fresh-keeping layer to prepare the anti-mold and fresh-keeping coating.

[0041]Step S2: forming a surface decoration layer on the front of the cardboard base layer, coating a barrier coating on the back of the cardboard base layer, and drying to form a barrier coating.

[0042] Preferably, the coating amount of the barrier coating is 1 to 10 g / m 2 , so as to control the thickness of the barrier coating to be 0.5-10 μm.

[0043] Preferably, the drying condition is to treat at 80-120° C. for 5-10 seconds. Preferably, the drying conditions are sequentially treating at 80-85°C, 90-100°C, 105-120°C, 90-100°C and 80-85°C for 1-2s respectively. More preferably, the drying ...

Embodiment 1

[0051] Mix 60 parts of polyurethane graft-modified PVDC emulsion, 12 parts of acrylate copolymer, 5 parts of water and 8 parts of isothiazolinone to prepare a barrier coating. Wherein, the acrylate copolymer is methyl methacrylate-butyl acrylate-acrylic acid-N-methylol acrylamide copolymer.

[0052] Mix 30 parts of ethylene-vinyl acetate copolymer with a degree of hydrolysis of 40%, 35 parts of acrylic ester copolymer, 8 parts of calcium propionate and 8 parts of water to prepare an anti-mold and fresh-keeping coating. Wherein, the acrylic ester copolymer is a methyl methacrylate-butyl acrylate-acrylic acid copolymer and a methyl methacrylate-butyl acrylate-acrylic acid-N-methylol acrylamide copolymer with a mass ratio of 1.

[0053] Form a surface decoration layer on the front of the cardboard base layer, according to 10g / m 2 The coating amount of the barrier coating is applied to the back of the cardboard base layer, and then dried at 80°C, 90°C, 120°C, 100°C and 85°C for 1...

Embodiment 2

[0056] Embodiment 2 is basically the same as Embodiment 1, and the difference is that the preparation raw materials and coating process parameters of the barrier coating and the anti-mildew fresh-keeping coating are as follows:

[0057] Mix 65 parts of polyurethane graft-modified PVDC emulsion, 15 parts of acrylate copolymer, 8 parts of water and 5 parts of isothiazolinone to prepare a barrier coating.

[0058] Mix 35 parts of ethylene-vinyl acetate copolymer with a degree of hydrolysis of 65%, 30 parts of acrylic ester copolymer, 10 parts of calcium propionate and 10 parts of water to prepare an anti-mold and fresh-keeping coating. Among them, the acrylate copolymer of the anti-mold fresh-keeping coating is methyl methacrylate-butyl acrylate-acrylic acid copolymer and methyl methacrylate-butyl acrylate-acrylic acid-N-methylol with a mass ratio of 1:2. base acrylamide copolymer.

[0059] The coating amount of barrier coating and anti-mildew fresh-keeping coating is 1g / m 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com