A preparation method of polyetheretherketone-based lithium battery diaphragm

A polyether ether ketone and battery separator technology, which is applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of technological lag in the development and improvement of diaphragm materials, difficult protection, poor mechanical strength, etc. Achieve good thermal stability and automatic shutdown protection performance, good spatial stability and flatness, and good molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

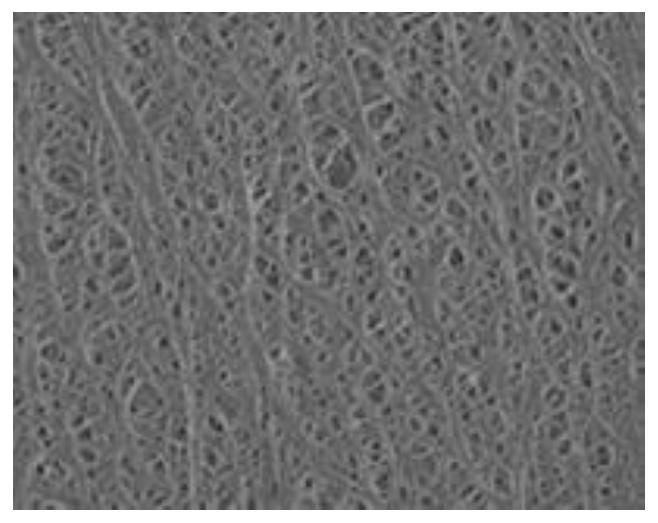

Image

Examples

Embodiment 1

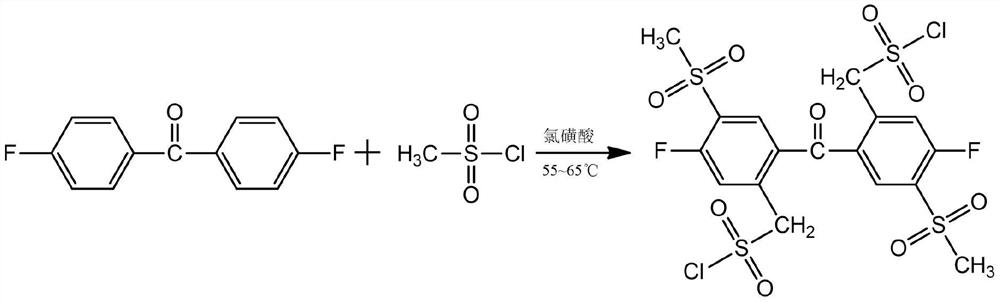

[0037] 1. Synthesis of chlorosulfonated fluoroketone monomer

[0038] Put 4,4,-difluorobenzophenone (20 parts), methanesulfonyl chloride (25 parts), and chlorosulfonic acid (55 parts) into a three-neck flask equipped with stirring, a thermometer, and a condensing reflux device. Stir continuously under low temperature for 60 min; the system is heated up to 55°C and continue to stir for 120 min. After the reaction is complete, the reaction product is filtered and washed with deionized water to obtain chlorosulfonated fluoroketone crystals;

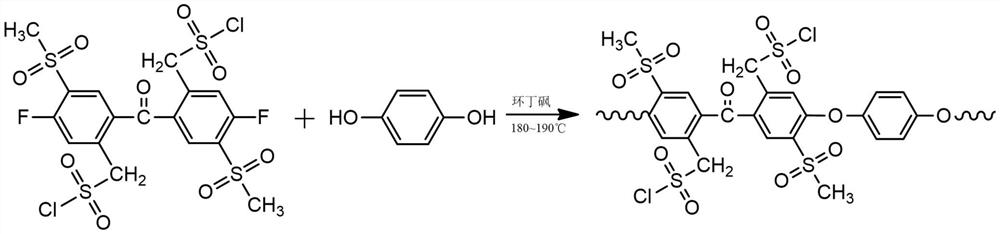

[0039] 2. Synthesis of sulfonated polyetheretherketone

[0040] In a three-necked flask equipped with a stirrer, a thermometer, and a condensing reflux device, add the chlorosulfonated monomer (5 parts), hydroquinone (5 parts), sodium carbonate (5 parts), sulfolane (85 parts), react under the continuous protection of high-purity nitrogen, raise the temperature to 120°C, and keep the temperature constant for 30 minutes; 300min; Finally, pou...

Embodiment 2

[0048] 1. Synthesis of chlorosulfonated fluoroketone monomer

[0049] Put 4,4,-difluorobenzophenone (25 parts), methanesulfonyl chloride (25 parts), and chlorosulfonic acid (50 parts) into a three-necked flask equipped with stirring, a thermometer, and a condensing reflux device. Stir continuously under low temperature for 60 min; the system is heated up to 55°C and continue to stir for 120 min. After the reaction is complete, the reaction product is filtered and washed with deionized water to obtain chlorosulfonated fluoroketone crystals;

[0050] 2. Synthesis of sulfonated polyetheretherketone

[0051] In a three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, add the chlorosulfonated monomer (10 parts), hydroquinone (10 parts), sodium carbonate (10 parts), sulfolane (70 parts), react under the continuous protection of high-purity nitrogen, raise the temperature to 120°C, and keep the temperature constant for 30 minutes; 300min; Finally, pour t...

Embodiment 3

[0059] 1. Synthesis of chlorosulfonated fluoroketone monomer

[0060] Put 4,4,-difluorobenzophenone (30 parts), methanesulfonyl chloride (25 parts), and chlorosulfonic acid (45 parts) into a three-neck flask equipped with stirring, a thermometer, and a condensing reflux device. Stir continuously under low temperature for 60 min; the system is heated up to 55°C and continue to stir for 120 min. After the reaction is complete, the reaction product is filtered and washed with deionized water to obtain chlorosulfonated fluoroketone crystals;

[0061] 2. Synthesis of sulfonated polyetheretherketone

[0062] In a three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, add the chlorosulfonated monomer (15 parts), hydroquinone (15 parts), sodium carbonate (10 parts), sulfolane (60 parts), react under the continuous protection of high-purity nitrogen, raise the temperature to 120°C, and keep the temperature constant for 30 minutes; 300min; Finally, pour the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com