Lithium battery diaphragm

A battery diaphragm and diaphragm technology, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as weak binding force, achieve the effects of increasing service life, promoting rapid fusion, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

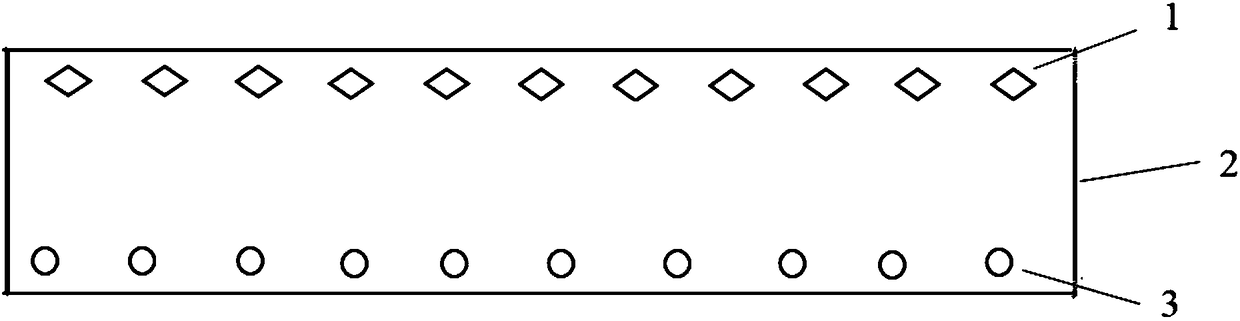

Embodiment 1

[0041] The battery separator provided in this example adopts vinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) as the material of the membrane base, and there are conductive layers and reinforcing layers on both sides of the membrane base, wherein conductive layers are dispersed in the conductive layer. Particle acetylene black, particle reinforcement nano-alumina is dispersed in the reinforcement layer. Both the conductive layer and the reinforcement layer of this battery separator had a thickness of 15 μm, and the thickness of the center portion was 25 μm.

[0042] The improved battery separator provided in this example is prepared by the following steps:

[0043] Dissolve 5g of PVDF-HFP in 200mL of acetone, heat, seal and stir until PVDF-HFP is completely dissolved, then use an automatic film applicator to coat a glass plate, and dry it in an oven at 110°C to obtain a PVDF-HFP base film ;

[0044] Dissolve 2g of PVDF-HFP in 200mL of acetone, heat, seal and stir...

Embodiment 2

[0048] The battery separator provided in this example adopts polyvinylidene fluoride as the material of the membrane substrate, and there are conductive layers and reinforcing layers on both sides of the membrane substrate, wherein conductive carbon black is dispersed in the conductive layer, and particle reinforcement is dispersed in the reinforcing layer. bulk titanium dioxide. In this battery separator, the thickness of the conductive layer was 10 μm, the thickness of the reinforcing layer was 25 μm, and the thickness of the center portion was 20 μm.

[0049] The improved battery separator provided in this example is prepared by the following steps:

[0050] Dissolve 5g of polyvinylidene fluoride (PVDF) in 200mL of N-methylpyrrolidone, heat, seal and stir until PVDF is completely dissolved, then use an automatic film applicator to coat a glass plate, and dry it in an oven to obtain PVDF basement membrane;

[0051] Dissolve 2g of PVDF in 200mL of N-methylpyrrolidone, heat,...

Embodiment 3

[0055] The battery separator provided in this embodiment adopts polyvinylpyrrolidone (PVP) as the material of the film base, and there are conductive layers and reinforcing layers on both sides of the film base, wherein carbon nanotubes are dispersed in the conductive layer, and carbon nanotubes are dispersed in the reinforcing layer. Granular reinforced silica. In this battery separator, the thickness of the conductive layer was 25 μm, the thickness of the reinforcing layer was 25 μm, and the thickness of the central portion was 50 μm.

[0056] The improved battery separator provided in this example is prepared by the following steps:

[0057] Dissolve 5g of PVP in 200mL of N-methylpyrrolidone, heat, seal and stir until the PVP is completely dissolved, then use an automatic film applicator to coat a glass plate, and dry it in an oven to obtain a PVP base film;

[0058] Dissolve 2g of PVP in 200mL of N-methylpyrrolidone, heat and seal it and stir until the PVP is completely d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com