Preparation method and application of a micro-nano structure iron oxide/carbon composite material

A carbon composite material, iron oxide technology, applied in nanotechnology, structural parts, nanotechnology and other directions for materials and surface science, can solve the problems of long preparation cycle, low output, complex process, etc., and achieve excellent cycle performance, The effect of high specific capacity and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further elaborate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the preferred embodiments, a description of the preparation method and application of a micro-nano structure iron oxide / carbon composite material proposed according to the present invention Specific embodiments, methods, steps, features and effects thereof are described in detail as follows:

[0032] Implementation column 1:

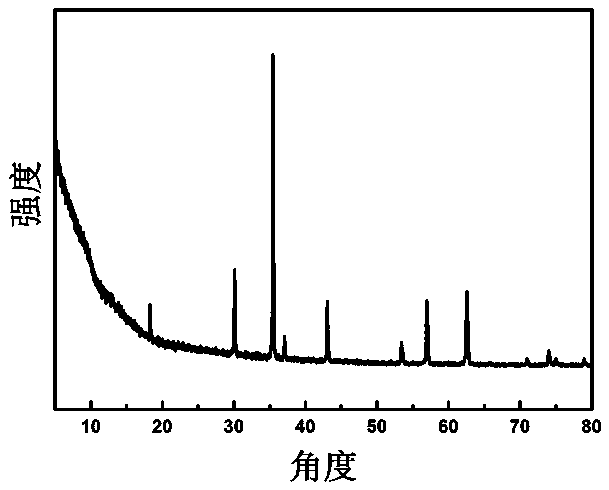

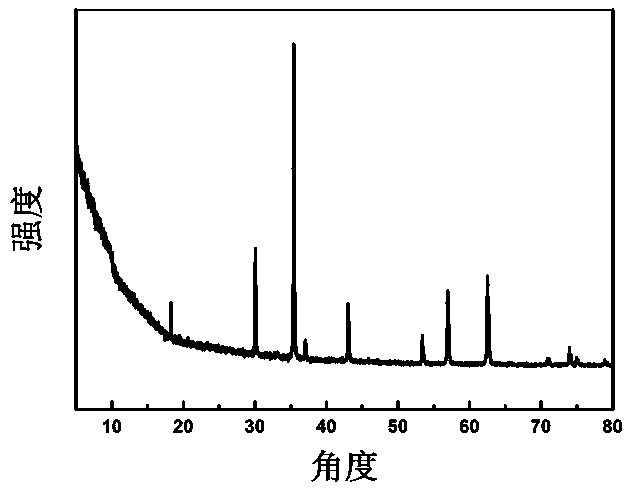

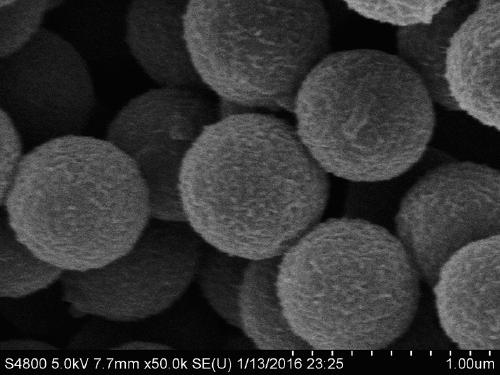

[0033] Weigh 0.20g of ferric nitrate nonahydrate, dissolve it in 5ml of glycerol, then add 35ml of absolute ethanol, stir evenly to form an orange-yellow solution with a molar concentration of iron ions of 0.0125 mol / L; then add 0.1g of glucose and stir until it is completely Dissolve, continue to stir for 5 minutes, transfer the mixed solution into a 50ml hydrothermal kettle, heat reaction at 180°C for 12 hours, cool to room temperature, then wash with deionized water and absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com