Novel negative electrode material for lithium-ion/potassium-ion battery and preparation method thereof

A battery negative electrode and lithium ion technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems that it is difficult for inorganic materials to store lithium ions and potassium ions, and it is difficult to realize the application of electrode materials, and achieve excellent cycle stability , low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

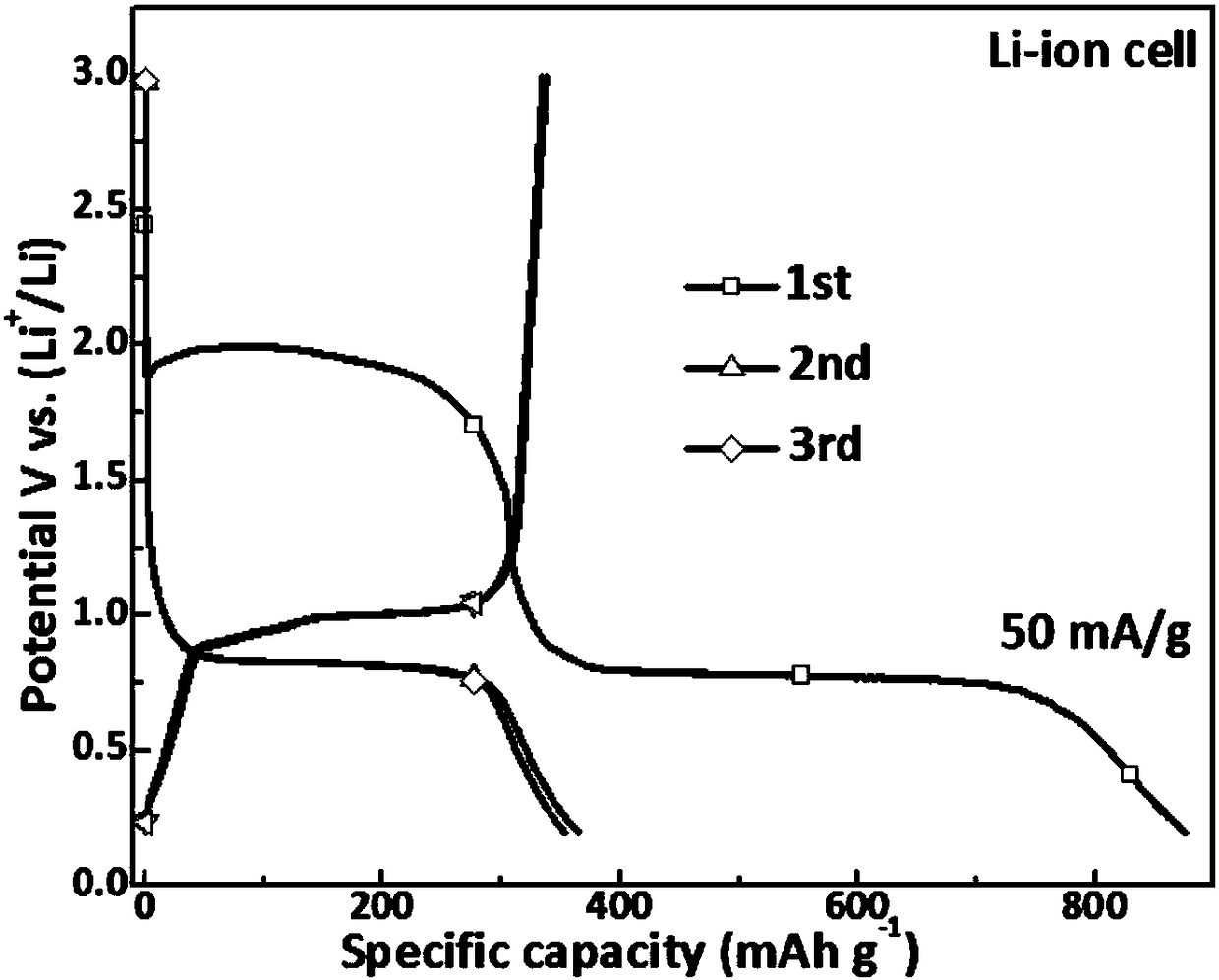

[0030] A novel lithium-ion / potassium-ion battery negative electrode material, the preparation method of which comprises the following steps:

[0031] (1) Weigh 2g of terephthalic acid and 1g of super P, mix the two, put them into a ball mill jar, add 20mL of distilled water, mill at a speed of 400r / min for 4h, take out the ball mill, and bake at 120°C for 24h ;

[0032] (2) Weigh 225 mg of the product of step (1), put it into an agate mortar, add 1 mL of LA132 binder with a concentration of 25 mg / mL, and grind for 30 min to obtain a slurry;

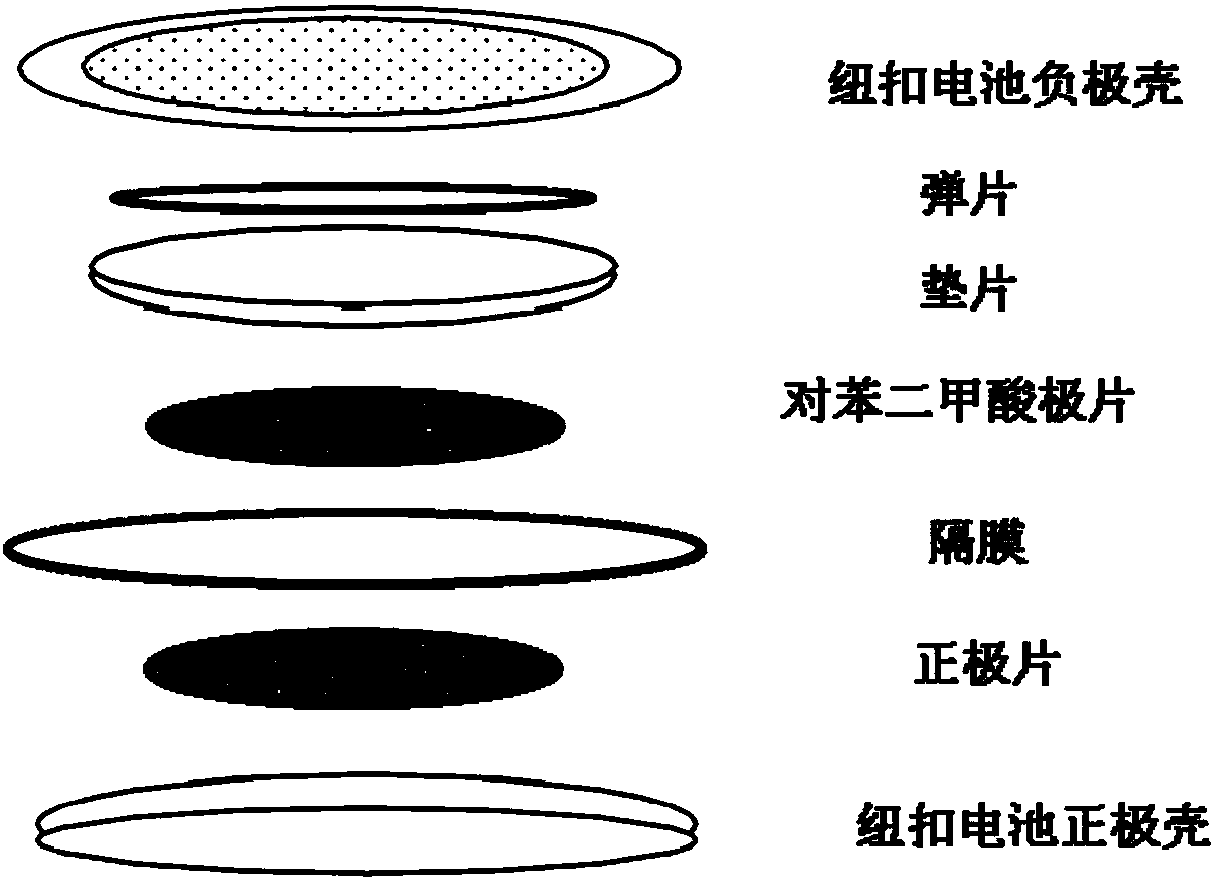

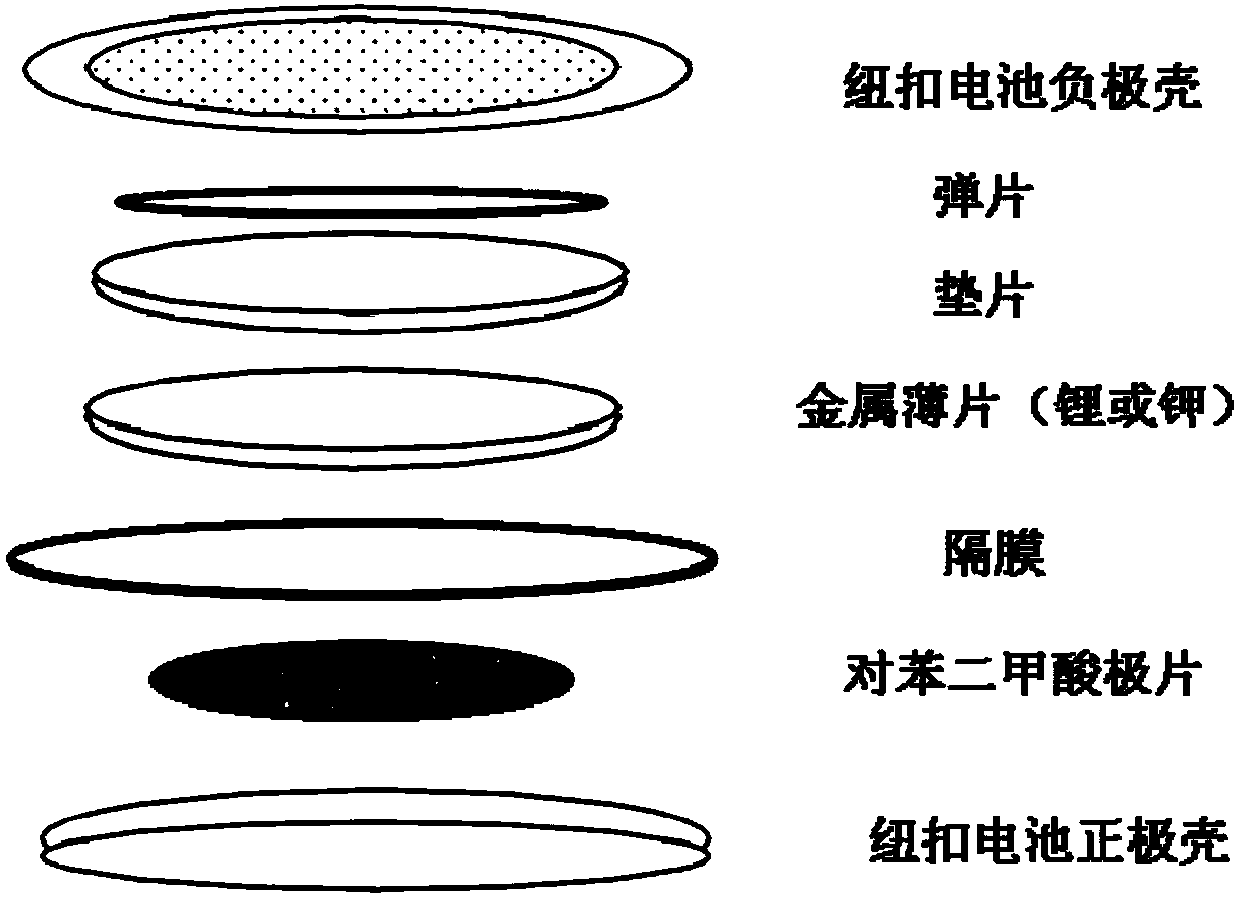

[0033] (3) Coating the slurry obtained in step (2) evenly on the copper foil, drying at 60° C., and then punching holes with a puncher with a diameter of 10 mm to prepare terephthalic acid electrode sheets.

Embodiment 2

[0035] A novel lithium-ion / potassium-ion battery negative electrode material, the preparation method of which comprises the following steps:

[0036] (1) Weigh 2g of terephthalic acid and 0.8g of conductive carbon black, mix the two, put them into a ball mill jar, add 20mL of distilled water, and ball mill at a speed of 400r / min for 4h, take out the ball mill material, Bake for 24 hours;

[0037] (2) Weigh 225 mg of the product of step (1), put it into an agate mortar, add 2 mL of LA132 binder with a concentration of 25 mg / mL, and grind for 30 min to obtain a slurry;

[0038] (3) Coating the slurry obtained in step (2) evenly on the copper foil, drying at 60° C., and then punching holes with a puncher with a diameter of 10 mm to prepare terephthalic acid electrode sheets.

Embodiment 3

[0040] A novel lithium-ion / potassium-ion battery negative electrode material, the preparation method of which comprises the following steps:

[0041] (1) Weigh 5g of terephthalic acid and 2g of super P, mix the two, put them into a ball mill jar, add 40mL of distilled water, mill at a speed of 400r / min for 4h, take out the ball mill, and bake at 120°C for 24h ;

[0042] (2) Weigh 225 mg of the product of step (1), put it into an agate mortar, add 1 mL of LA132 binder with a concentration of 25 mg / mL, and grind for 30 min to obtain a slurry;

[0043] (3) Coating the slurry obtained in step (2) evenly on the copper foil, drying at 60° C., and then punching holes with a puncher with a diameter of 10 mm to prepare terephthalic acid electrode sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com