Lithium battery electrolyte and lithium battery

A lithium battery and electrolyte technology, applied in the field of electrochemistry, can solve the problems of reducing the service life of lithium batteries, accelerating the decomposition of lithium hexafluorophosphate, destroying the SEI film, etc., and achieving the effects of low production cost, stable electrochemical properties and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

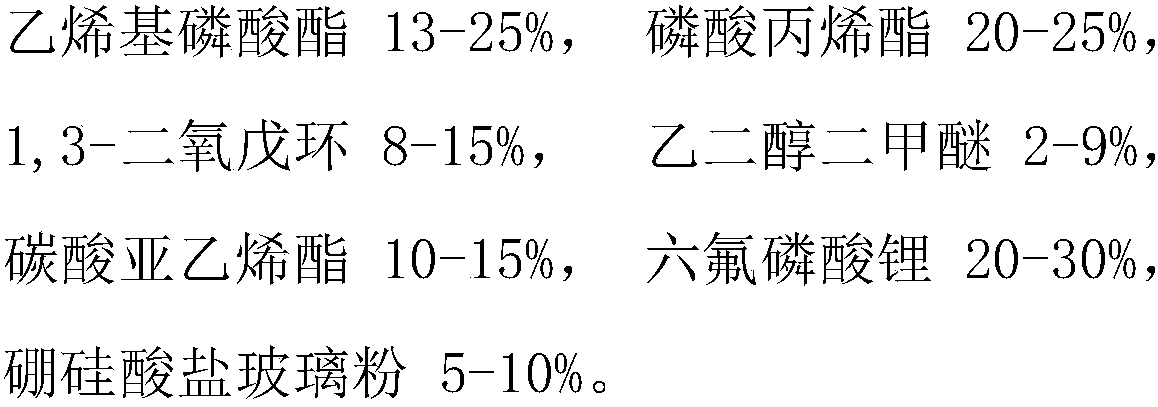

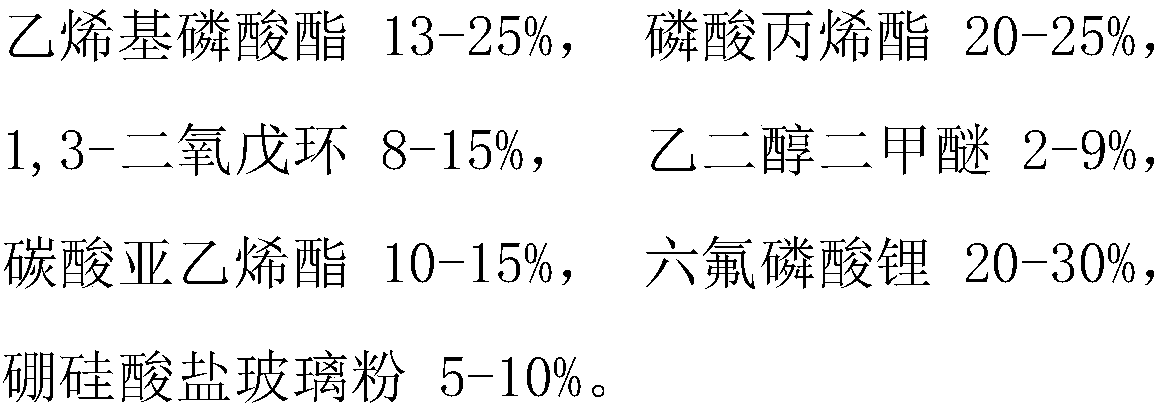

[0021] This embodiment is composed of the following substances in mass ratio: vinyl phosphate 18%, propylene phosphate 20%, 1,3-dioxolane 15%, ethylene glycol dimethyl ether 2%, vinylene carbonate 15% %, lithium hexafluorophosphate 20%, borosilicate glass powder 10%.

[0022] The electrolyte generated in this embodiment meets the electrolyte quality standard formulated in the chemical industry standard "HG / T 4067-2008" of the People's Republic of China, wherein the water content is 15ppm, the hydrofluoric acid content is 41ppm, and the conductivity at 25°C is 10.28ms / cm. The aluminum foil and copper foil were placed in the electrolyte produced in this example. Among them, the aluminum foil was completely corroded after 23 months, which was 16 months longer than the corrosion time of common electrolytes on the market; the copper foil was corroded after 18 months. Completely, it is 12 months longer than the corrosion time of ordinary electrolytes on the market.

Embodiment 2

[0024] This embodiment is composed of the following substances in mass ratio: vinyl phosphate 13%, propylene phosphate 25%, 1,3-dioxolane 8%, ethylene glycol dimethyl ether 9%, vinylene carbonate 10% %, lithium hexafluorophosphate 30%, borosilicate glass powder 5%.

[0025] The electrolyte generated in this embodiment meets the electrolyte quality standard formulated in the chemical industry standard "HG / T 4067-2008" of the People's Republic of China, wherein the water content is 17ppm, the hydrofluoric acid content is 42ppm, and the conductivity at 25°C is 10.16ms / cm. The aluminum foil and copper foil were placed in the electrolyte produced in this example, and the aluminum foil was completely corroded after 28 months, which was 19 months longer than the corrosion time of common electrolytes on the market; the copper foil was corroded after 21 months Completely, it is 14 months longer than the corrosion time of ordinary electrolytes on the market.

Embodiment 3

[0027] This embodiment is composed of the following substances in mass ratio: vinyl phosphate 15%, propylene phosphate 22%, 1,3-dioxolane 10%, ethylene glycol dimethyl ether 5%, vinylene carbonate 13% %, lithium hexafluorophosphate 28%, borosilicate glass powder 7%.

[0028] The electrolyte generated in this embodiment meets the electrolyte quality standard formulated in the chemical industry standard "HG / T 4067-2008" of the People's Republic of China, wherein the water content is 13ppm, the hydrofluoric acid content is 46ppm, and the conductivity at 25°C is 10.73 ms / cm. Aluminum foil and copper foil were placed in the electrolyte prepared in this example. Among them, the aluminum foil was completely corroded after 25 months, which was 14 months longer than the corrosion time of common electrolytes on the market; the copper foil was corroded after 19 months. Completely, it is 13 months longer than the corrosion time of ordinary electrolytes on the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com