Compound plant essential oil micro-capsule preparation and preparation method thereof

A plant essential oil and preparation technology, which is applied in the field of compound plant essential oil microcapsule preparations for livestock and poultry and its preparation, can solve the problems of general fluidity and dispersibility, influence on selling price and profitability, uneven particle size, etc., and achieve weak antibacterial ability. , The effect of improving resistance and uniform distribution of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

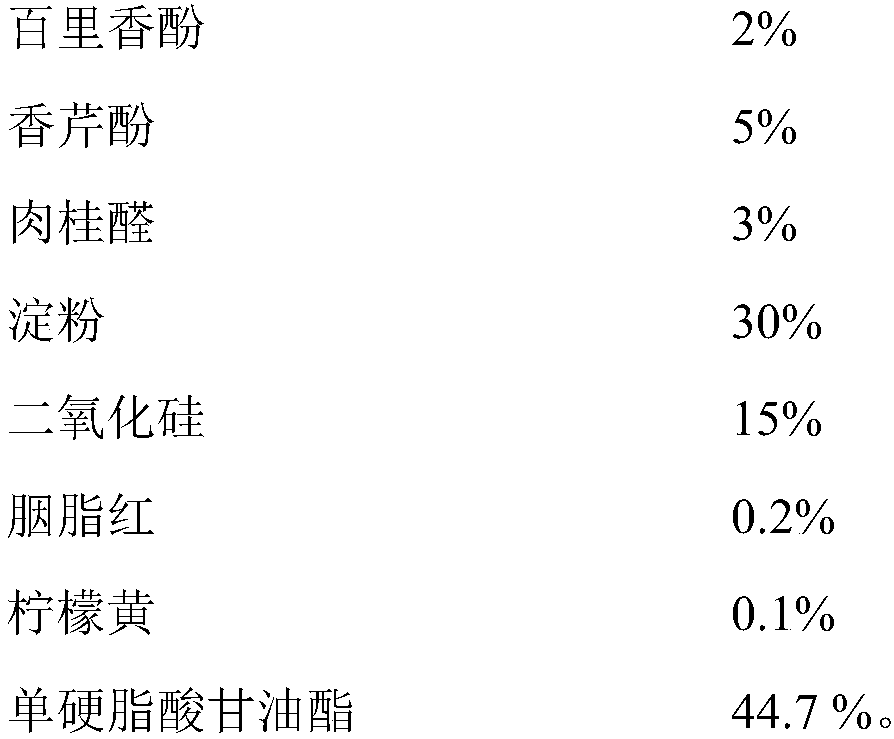

[0042] A compound plant essential oil microcapsule preparation, including the following components by mass percentage:

[0043]

[0044] Preparation method: (1) Weigh the carrier excipient glyceryl monostearate according to the formula ratio, heat it to 70-90°C to melt, and mix for 30 minutes to make it uniform. The reason for mixing while heating is that the temperature may be uneven during heating. If the material is not mixed, the material will change from solid to molten state, and the inner and outer layers and the upper and lower layers may be heated unevenly, resulting in a single uniform molten state. materials.

[0045] (2) Weigh the plant essential oil raw materials in a suitable container according to the formula ratio, then add an appropriate amount of the carrier auxiliary materials obtained in step (1), mix evenly to obtain a pre-mixed uniform material, and then add it to the balance step (1) In the treated carrier auxiliary material, stir evenly to obtain a mixed ma...

Embodiment 2

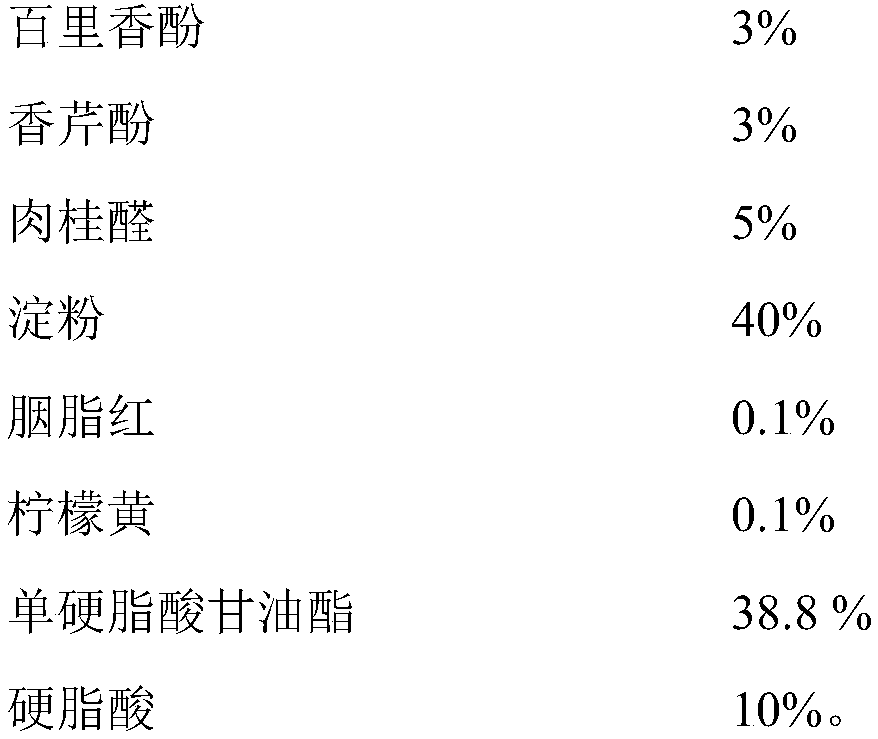

[0050] A compound plant essential oil microcapsule preparation, including the following components by mass percentage:

[0051]

[0052] Preparation method: (1) Weigh the carrier excipients glyceryl monostearate and stearic acid according to the formula ratio, heat to 90-100°C to melt, and mix for 40 minutes to make it uniform.

[0053] (2) Weigh the plant essential oil raw materials in a suitable container according to the formula ratio, then add an appropriate amount of the carrier auxiliary materials obtained in step (1), mix evenly to obtain a pre-mixed uniform material, and then add it to the balance step (1) In the treated carrier auxiliary material, stir evenly to obtain a mixed material.

[0054] (3) According to the formula ratio, add auxiliary materials and pigments to the materials of step (2), stir evenly, and obtain uniform materials.

[0055] (4) The uniform material obtained in step (3) is cooled to 60-70°C, and granulated by a high-speed spray granulating machine, and ...

Embodiment 3

[0058] A compound plant essential oil microcapsule preparation, including the following components by mass percentage:

[0059]

[0060]

[0061] Preparation method: (1) Weigh the carrier and auxiliary material paraffin according to the formula ratio, heat it to 100-120°C to melt, and mix for 40 minutes to make it uniform.

[0062] (2) Weigh the plant essential oil raw materials in a suitable container according to the formula ratio, then add an appropriate amount of the carrier auxiliary materials obtained in step (1), mix evenly to obtain a pre-mixed uniform material, and then add it to the balance step (1) In the treated carrier auxiliary material, stir evenly to obtain a mixed material.

[0063] (3) According to the formula ratio, add auxiliary materials and pigments to the materials of step (2), stir evenly, and obtain uniform materials.

[0064] (4) The uniform material obtained in step (3) is cooled to 60-70°C, and granulated by a high-speed spray granulation machine, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com