Preparation method for maleic anhydride modified hydrothermal bamboo charcoal adsorbent

A technology of maleic anhydride and adsorbent, which is applied in the field of preparation of maleic anhydride-modified hydrothermal bamboo charcoal adsorbent, can solve the problems of low utilization rate of bamboo resources, achieve easy reaction device, easy operation method, and low risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Propose a kind of preparation method of maleic anhydride modified hydrothermal bamboo charcoal adsorbent in the present embodiment, carry out according to the following steps:

[0019] (1) Maleic anhydride modified hydrothermal bamboo charcoal: mix hydrothermal bamboo charcoal and maleic anhydride evenly, then react at 120-140°C for 2-6 hours, cool naturally, stir in distilled water, filter and wash with distilled water, get semi-finished products;

[0020] (2) Maleate modified semi-finished product: Add the semi-finished product to saturated sodium bicarbonate solution and stir, then filter, wash until neutral, and dry to obtain the finished product.

[0021] A method for preparing maleic anhydride-modified hydrothermal bamboo charcoal adsorbent, hydrothermal bamboo charcoal preparation: put bamboo powder and concentrated hydrochloric acid in water, stir and mix evenly at room temperature, place in a reaction kettle, and then react at 200°C 12 hours, natural cooling, ...

Embodiment 2

[0028] A method for preparing maleic anhydride-modified hydrothermal bamboo charcoal adsorbent, hydrothermal bamboo charcoal preparation: 40 parts by weight of 60-80 mesh bamboo powder and 8 parts by weight of concentrated hydrochloric acid are placed in 72 parts by weight of water, stirred and mixed evenly at room temperature Then put it in a stainless steel reaction kettle lined with polytetrafluoroethylene, then react at 200°C for 12 hours, cool naturally, filter with suction, wash until neutral, and then dry to obtain hydrothermal bamboo charcoal. Mix 40 parts by weight of hydrothermal bamboo charcoal and 40 parts by weight of maleic anhydride evenly, react at 130°C for 4 hours, cool naturally, place in 300 parts by weight of distilled water, filter and wash with distilled water to obtain a semi-finished product. Maleate modification of the semi-finished product: adding the semi-finished product to 200 parts by weight of saturated sodium bicarbonate solution and stirring, t...

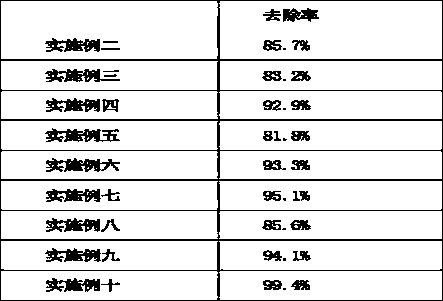

Embodiment 3

[0030] A method for preparing maleic anhydride-modified hydrothermal bamboo charcoal adsorbent, hydrothermal bamboo charcoal preparation: 40 parts by weight of 60-80 mesh bamboo powder and 8 parts by weight of concentrated hydrochloric acid are placed in 72 parts by weight of water, stirred and mixed evenly at room temperature Then put it in a stainless steel reaction kettle lined with polytetrafluoroethylene, then react at 200°C for 12 hours, cool naturally, filter with suction, wash until neutral, and then dry to obtain hydrothermal bamboo charcoal. Mix 40 parts by weight of hydrothermal bamboo charcoal and 20 parts by weight of maleic anhydride evenly, react at 130°C for 4 hours, cool naturally, place in 300 parts by weight of distilled water, filter and wash with distilled water to obtain a semi-finished product. Maleate modification of the semi-finished product: adding the semi-finished product to 200 parts by weight of saturated sodium bicarbonate solution and stirring, t...

PUM

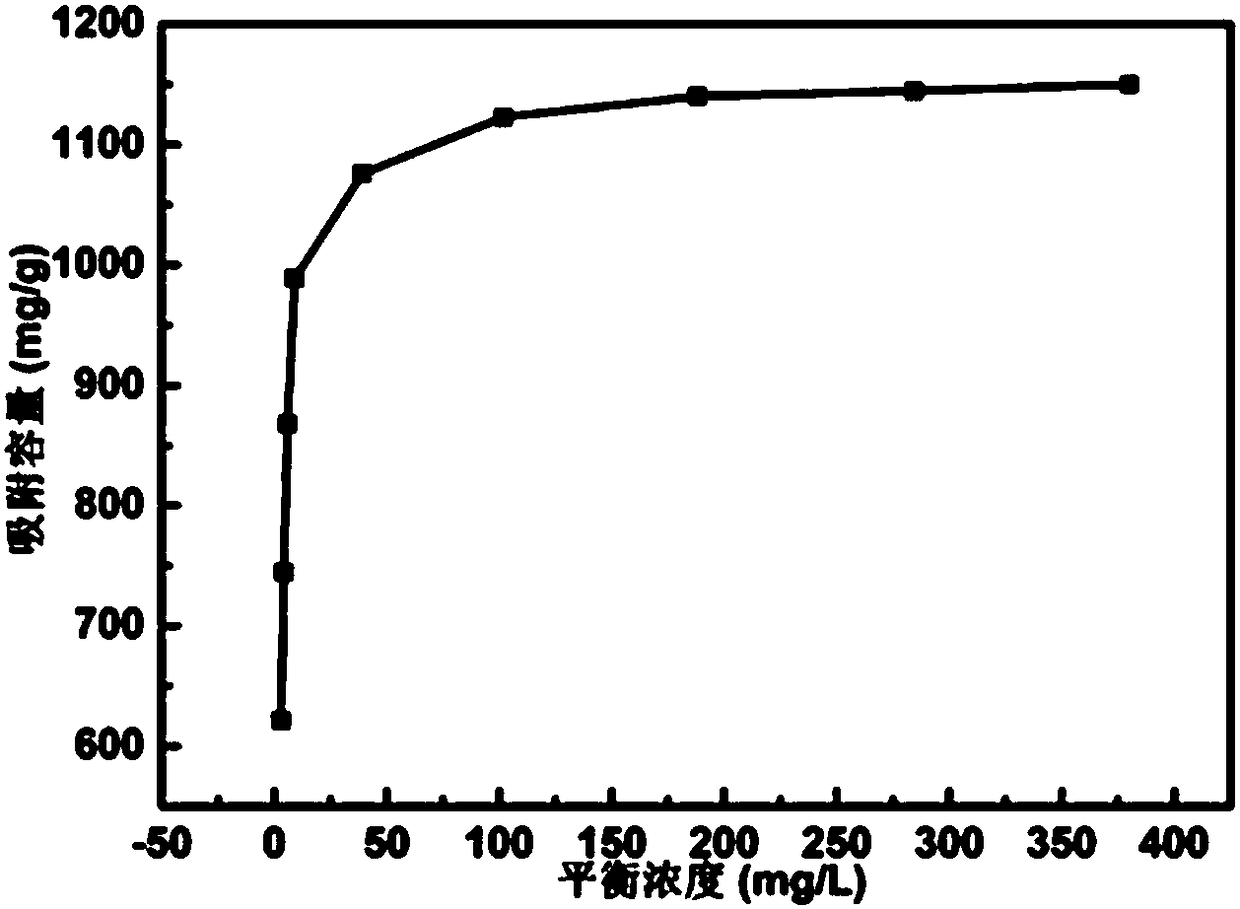

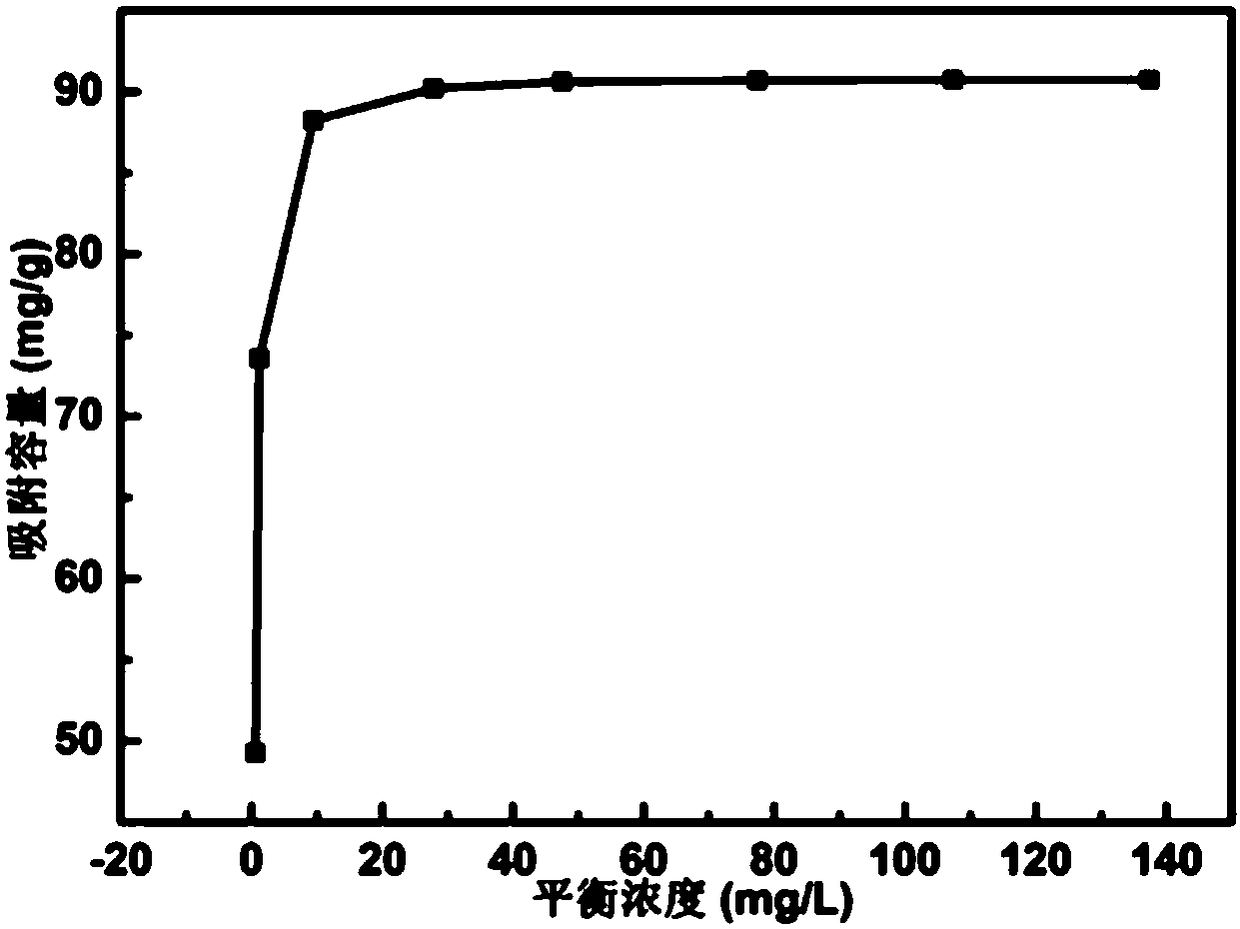

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com