Water-borne bicomponent inorganic modified heat-resistant wood paint and preparation method and use method thereof

An inorganic modification, two-component technology, applied in the field of paint, can solve the problems of boiling water resistance, poor resistance to cigarette butt scalding, serious pollution of oily wood paint, poor resistance to cigarette butt scalding, etc., to achieve excellent chemical resistance, improve Rigidity and chemical resistance, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

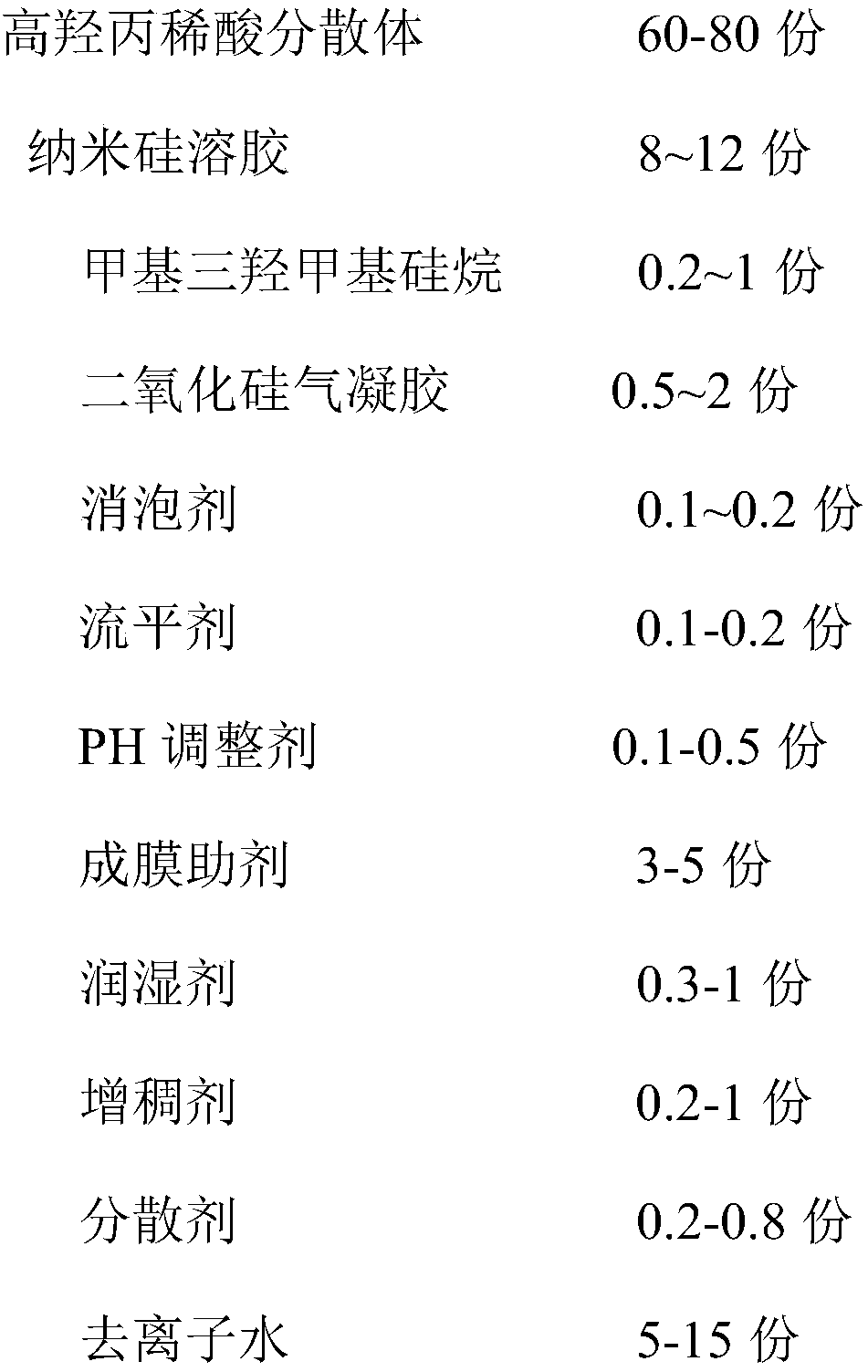

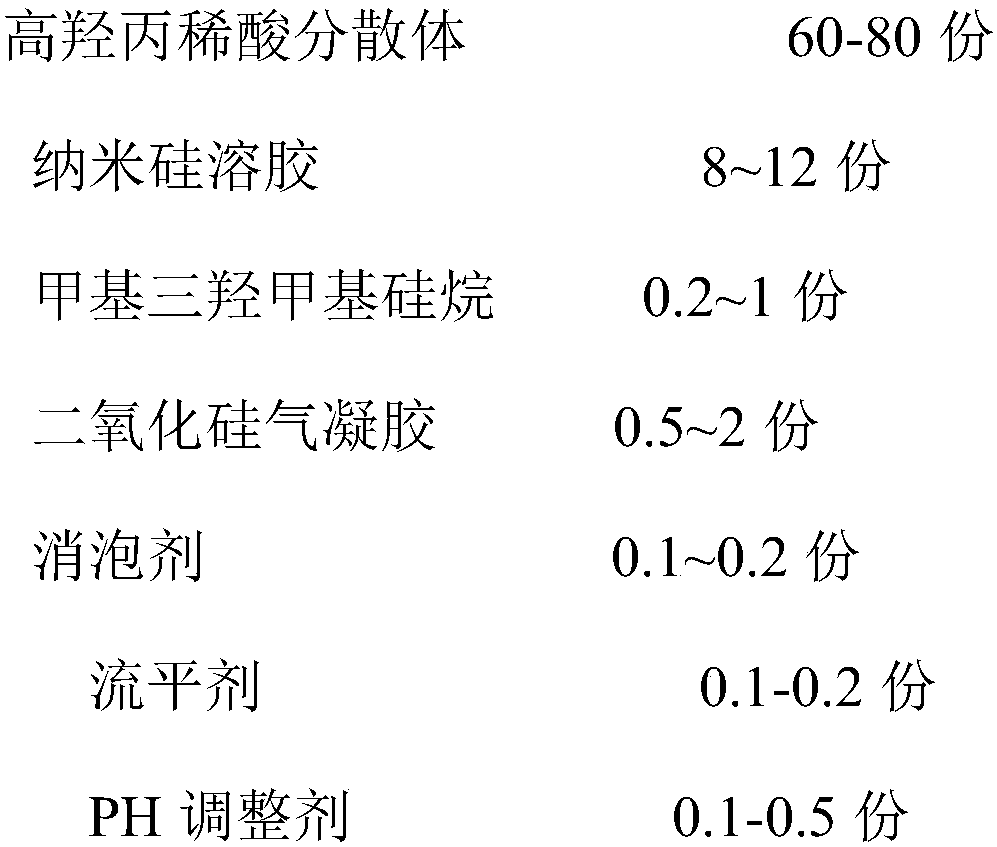

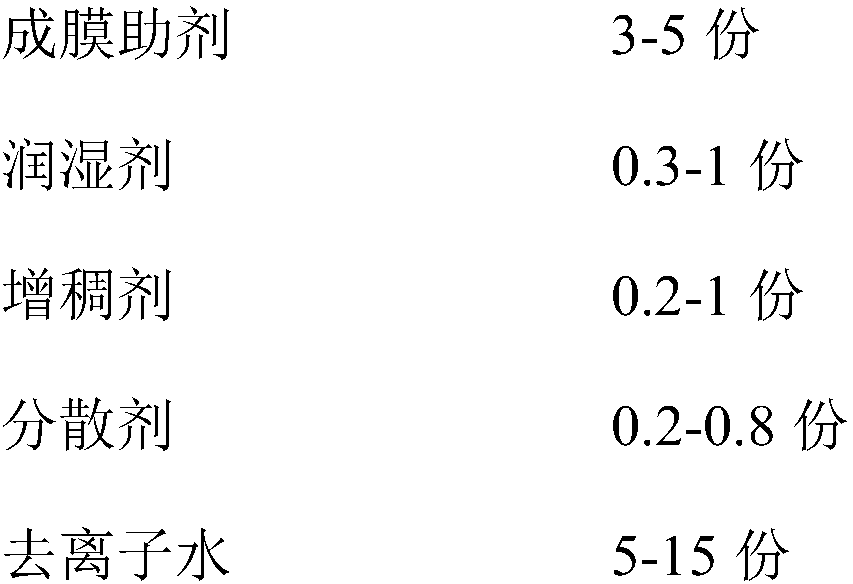

[0066] Get each component by the weight shown in embodiment 1 in table 1, and preparation method is according to the following steps:

[0067] Specific implementation steps:

[0068] Component A:

[0069] Step 1: adding high hydroxyacrylic acid dispersion resin into the paint mixing container;

[0070] Step two nano-silica sol surface treatment:

[0071] Add 20% deionized water in the formula to a container, slowly add 30% methyltrimethylolsilane in the formula under low-speed stirring at 400-500rpm, slowly add nano-silica sol, and then high-speed at 1000-1200rpm Disperse for 15 minutes to obtain the nano-silica sol surface treatment solution, and after standing for 60 minutes, slowly add the nano-silica sol surface treatment solution to the paint mixing container with the dispersion in step 1 under 400-500rpm low-speed stirring, and use 1000- Disperse at a high speed of 1200rpm for 30 minutes.

[0072] Step 3 Slowly add defoamer, wetting agent, leveling agent, and pH regu...

Embodiment 2

[0082] Take each component according to the weight of each component shown in Example 2 in Table 1, and repeat the method described in Example 1 to obtain component A and component B in Example 2;

[0083] According to component A: component B: water = 100:15:15, after mixing evenly, let it stand for ten minutes to defoam, the appearance of the obtained water-based two-component inorganic modified heat-resistant wood paint is: translucent, slightly white paint liquid , sprayed on the substrate plate that has been primed, wet film spraying amount: 90g / m 2 , Drying method: Surface drying of the paint film at room temperature for 35 minutes, hard drying time of 24 hours, and the comprehensive properties of the paint film measured after drying at room temperature for 7 days are shown in Table 2.

Embodiment 3

[0085] Take each component according to the weight of each component shown in Example 3 in Table 1, and repeat the method described in Example 1 to obtain component A and component B in Example 3;

[0086] According to component A: component B: water = 100:15:20, mix evenly, let it stand for ten minutes to defoam, the appearance of the obtained water-based two-component inorganic modified heat-resistant wood paint is: translucent, slightly white paint liquid , sprayed on the substrate plate that has been primed, wet film spraying amount: 90g / m 2 , Drying method: Surface drying of the paint film at room temperature for 40 minutes, hard drying time of 24 hours, and the comprehensive properties of the paint film measured after drying at room temperature for 7 days are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com