Preparation method of arsenic-added brass for forming corrosion-resistant and easy-bending pipes

A corrosion-resistant and pipe-bending technology, which is applied in the field of alloy manufacturing, can solve the problems of easy cutting and loss, achieve the effect of low lead content and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

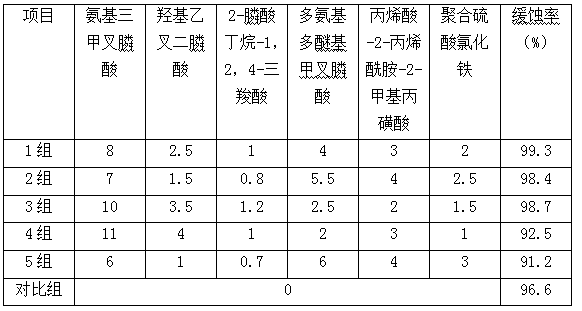

Examples

Embodiment 1

[0018] A preparation method of arsenic-added brass for forming corrosion-resistant and easy-bending pipes:

[0019] 1) Ingredients: Weigh the raw materials of each component, and its chemical components include copper 62.3-63%, lead 0-0.08%, iron 0.1-0.15%, nickel 0.1-0.5%, arsenic 0.02-0.1%, Antimony 0-0.005%, the balance is zinc;

[0020] 2) Smelting: Add 35% copper raw material into the casting furnace, raise the temperature to 365°C at a rate of 5°C / min, keep it for 1 hour, then raise the temperature to 665°C at a rate of 15°C / min, hold it for 30 minutes, and then Raise the temperature to 815°C at a rate of 5°C / min. After 10 minutes of heat preservation, add the proportioned amount of arsenic, smelt for 40 minutes, then raise the temperature to 940°C at a rate of 5°C / min, and add the proportioned amount of iron, Nickel, lead, and antimony were smelted for 40 minutes; then raised to 1080°C at a rate of 5°C / min, and kept for 5 minutes, adding the stated proportion of zinc a...

Embodiment 2

[0026] A preparation method of arsenic-added brass for forming corrosion-resistant and easy-bending pipes:

[0027] 1) Ingredients: Weigh the raw materials of each component, and its chemical components include copper 62.3-63%, lead 0-0.08%, iron 0.1-0.15%, nickel 0.1-0.5%, arsenic 0.02-0.1%, Antimony 0-0.005%, the balance is zinc;

[0028] 2) Melting: Put 40% copper raw material into the casting furnace, raise the temperature to 350°C at a rate of 5°C / min, keep it for 1 hour, then raise the temperature to 680°C at a rate of 15°C / min, hold it for 30 minutes, and then Raise the temperature to 830°C at a rate of 5°C / min, and after holding for 10 minutes, add the proportioned amount of arsenic, smelt for 50 minutes, then raise the temperature to 930°C at a rate of 5°C / min, add the proportioned amount of iron, Nickel, lead, and antimony were smelted for 35 minutes; then raised to 1100°C at a rate of 5°C / min, and kept for 5 minutes, adding the stated ratio of zinc and the balance ...

Embodiment 3

[0034] A preparation method of arsenic-added brass for forming corrosion-resistant and easy-bending pipes:

[0035] 1) Ingredients: Weigh the raw materials of each component, and its chemical components include copper 62.3-63%, lead 0-0.08%, iron 0.1-0.15%, nickel 0.1-0.5%, arsenic 0.02-0.1%, Antimony 0-0.005%, the balance is zinc;

[0036]2) Smelting: Add 30% copper raw material into the casting furnace, raise the temperature to 380°C at a rate of 5°C / min, keep it for 1 hour, then raise the temperature to 650°C at a rate of 15°C / min, hold it for 30 minutes, and then The temperature is raised to 800°C at a rate of 5°C / min, and after 10 minutes of heat preservation, the proportioned amount of arsenic is added, smelted for 30 minutes, and then raised to 950°C at a rate of 5°C / min, and the proportioned amount of iron, Nickel, lead, and antimony were smelted for 45 minutes; then raised to 1050°C at a rate of 5°C / min, and kept for 5 minutes, adding the stated ratio of zinc and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com