Magnetron sputtering preparation process of folding-resistant high-barrier composite packaging films

A preparation process and composite packaging technology, applied in the direction of sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of not being able to withstand folding, barrier films prone to cracks, etc., to reduce the permeability and cost, prolonging the shelf life of food, prolonging the effect of mildew and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparations for cleaning and drying of the base material; take PA as the base material, use acetone, alcohol, and deionized water to ultrasonically clean it for 15 minutes, and then send it to the blower unit for drying.

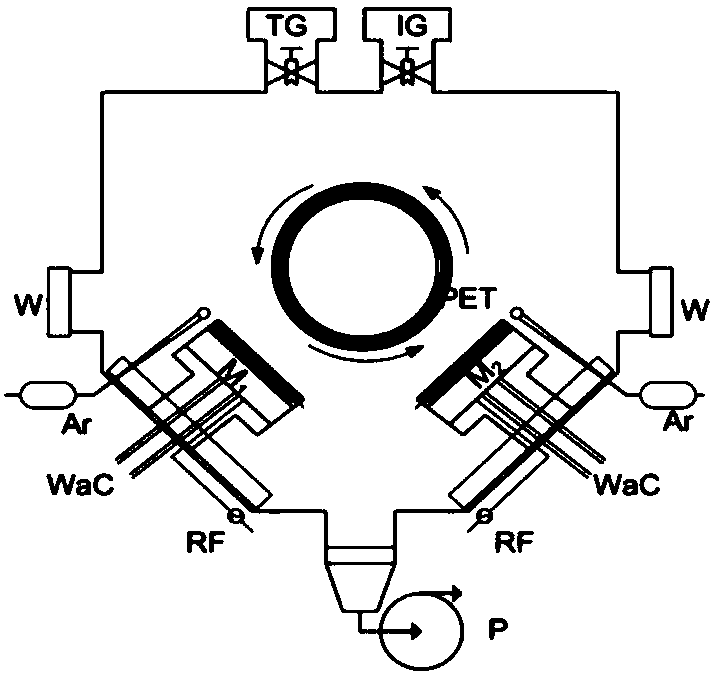

[0035] (2) Send the prepared substrate into the pre-sputtering vacuum box for pre-sputtering cleaning, the pre-sputtering gas is 999.99% argon, the sputtering power increase rate is 2W hours / square centimeter, and the sputtering time is 150 Second;

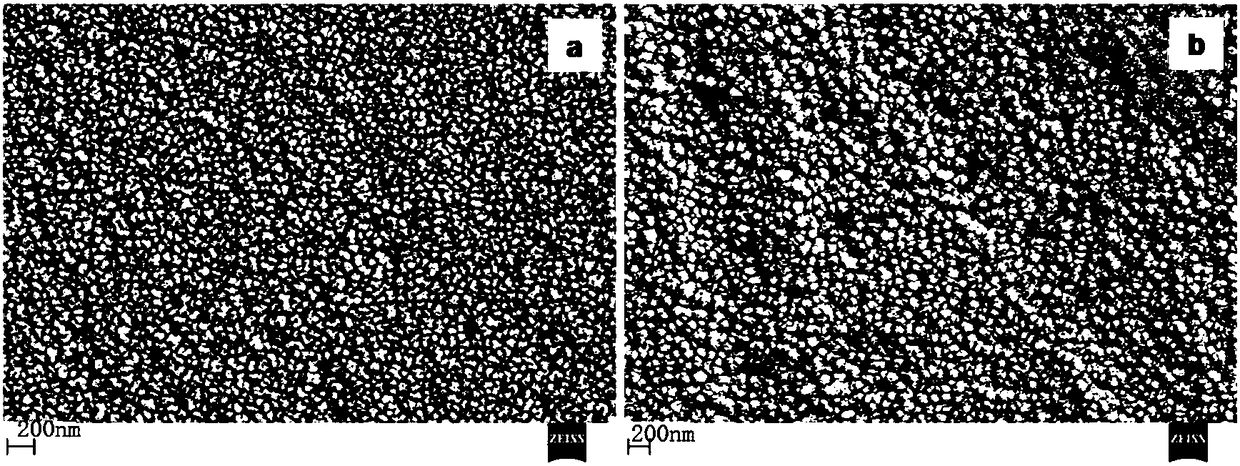

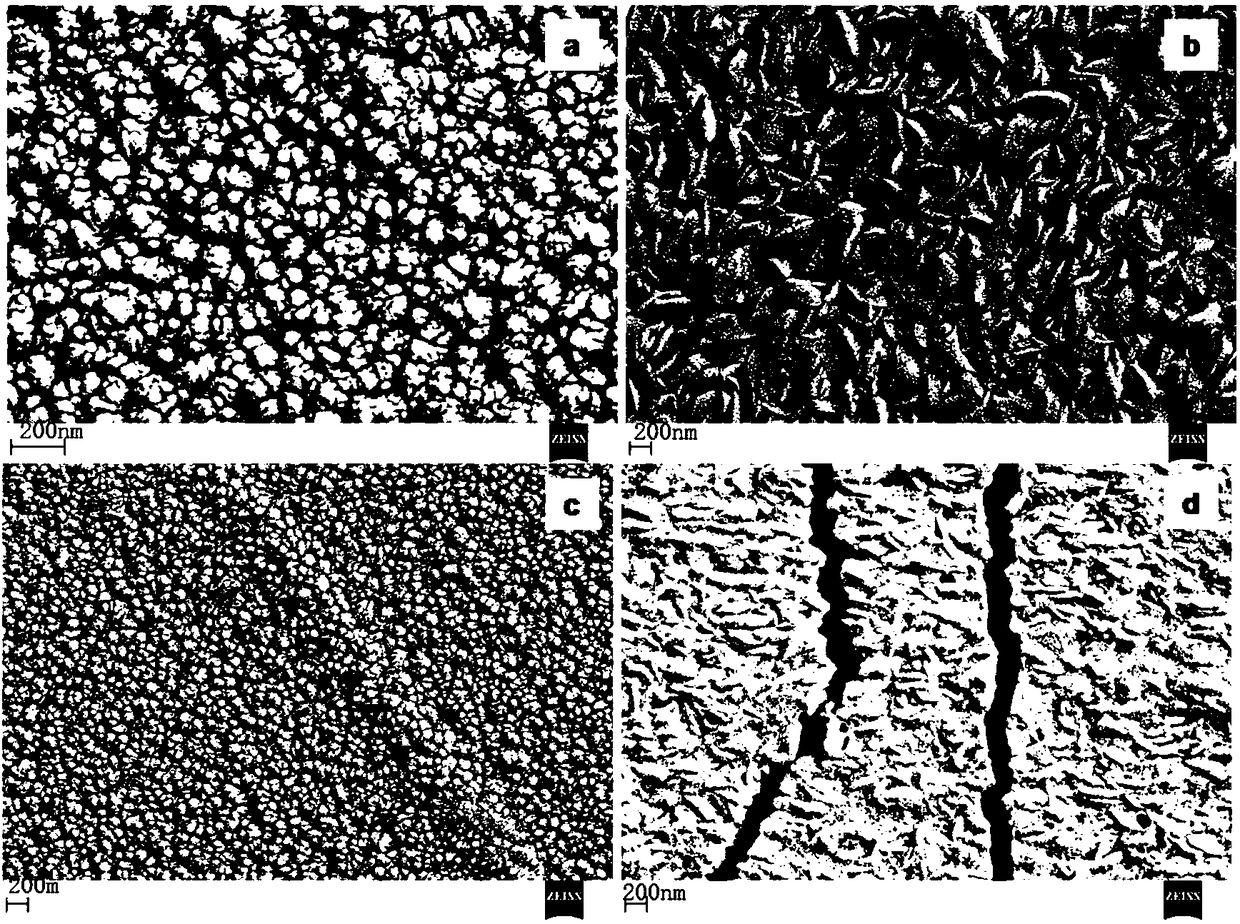

[0036] (3) Take PI and SiO respectively 2 As the target, turn on the RF power supply, and prepare C-SiO by co-deposition on the pre-sputtered substrate 2 Composite high-resistance film, the vacuum degree of the vacuum chamber is controlled at 4×10 -5 Pa, the working gas is 999.99% argon, the flow rate of argon is 50sccm, the working pressure is 0.4Pa, the distance between the target and the base is 10cm, the rotation speed of the drum is 1.5m / min, PI, SiO 2 The sputtering power was controlled at 1...

Embodiment 2

[0038] (1) Preparations for cleaning and drying the base material; using PET as the base material, use acetone, alcohol, and deionized water to ultrasonically clean it for 30 minutes, and then send it to the blower unit for drying.

[0039] (2) Send the prepared substrate into the pre-sputtering vacuum box for pre-sputtering cleaning, the pre-sputtering gas is 999.99% argon, the sputtering power increase rate is 2W hours / square centimeter, and the sputtering time is 100 Second;

[0040] (3) Using PI and ZnO as targets, turn on the RF power supply, and co-deposit F-Si composite high-resistance films on the pre-sputtered substrate. The vacuum degree of the vacuum chamber is controlled at 3×10-5Pa, and the working gas is 999.99% argon, the argon gas flow rate is 60sccm, the working pressure is controlled at 0.2Pa, the target base distance is 6cm, the drum rotation speed is controlled at 2m / min, and the sputtering power of PI and ZnO is controlled at 1W / cm². The sputtering time w...

Embodiment 3

[0042] (1) Preparations such as cleaning and drying of the substrate; 90 parts by weight of polyethylene terephthalate (PET), 6.5 parts by weight of polyethylene LLDPE flexible chain molecules, and 0.5-15 parts by weight of butanediol additives ; Use twin-screw to extrude the mixture of the above raw materials of polyethylene terephthalate to prepare composite PET, and the base temperature is controlled at 190-195 °C; and composite PET is used as the base material, respectively with acetone, alcohol, deionized water Ultrasonic cleaning for 30 minutes, and then sent to the blower to dry.

[0043] (2) Send the prepared composite PET substrate into the pre-sputtering vacuum box for pre-sputtering cleaning. The pre-sputtering gas is 999.99% argon, and the sputtering power increase rate is 1.5W hours / square centimeter. The time is 120 seconds;

[0044] (3) Using PTFE and ZnO as targets respectively, turn on the RF power supply, and perform co-deposition on the pre-sputtered substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com