Garbage incineration furnace low-energy-level working medium and coal fired boiler coupled high-energy-level utilization system

A waste incinerator and coal-fired boiler technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as low power generation efficiency, high equipment investment, high-temperature corrosion, etc., to reduce coal consumption for power generation, improve power generation efficiency, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

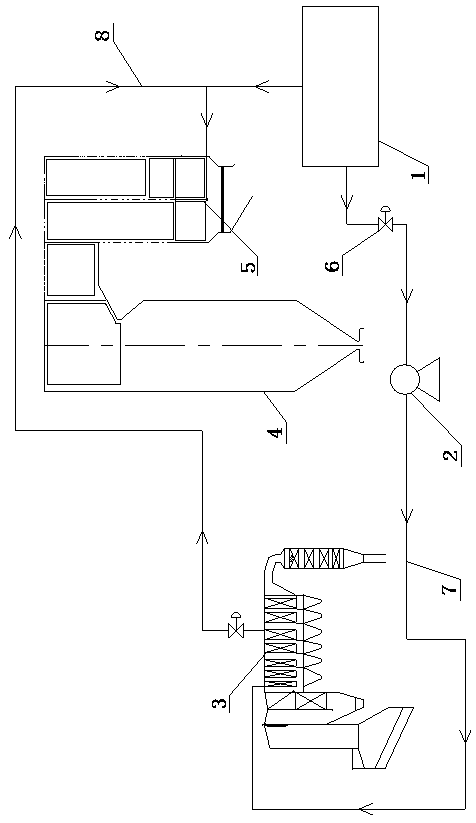

[0013] A high-energy utilization system in which a low-energy-level working fluid of a waste incinerator is coupled with a coal-fired boiler. The heating surface of the waste heat furnace of the furnace 3 is connected, and the outlet water pipe 8 of the waste incinerator is connected with the other water supply pipe of the high-pressure heater, and then connected with the tail economizer 5 of the coal-fired boiler 4. After being heated with the waste heat furnace Shut-off valves 6 are respectively arranged on the water supply pipeline connected on the surface and the outlet water pipeline of the garbage incinerator.

Embodiment 2

[0015] The superheated steam generation method of the above-mentioned waste incinerator low-energy-level working fluid coupled with the coal-fired boiler high-energy utilization system, the feed water enters the low-pressure heater through the feed water pump, and then enters the high-pressure heaters at all levels through the deaerator, and comes out from the high-pressure heater The working medium is divided into two routes, one of which is sent to the economizer inlet of the coal-fired boiler through the water supply pipeline, and the other is sent to the waste heat furnace for waste incineration through the water supply pipeline, passes through the heating surfaces of all levels, and is collected by the outlet pipeline of the final heating surface. into the inlet of the economizer of the coal-fired boiler, increase the inlet water temperature of the economizer of the coal-fired boiler, and raise the low-level unsaturated water to the high-level main Steam, realizing energy ...

Embodiment 3

[0017] According to the high-energy utilization system of the waste incinerator low-energy-level working fluid coupled with the coal-fired boiler described in Embodiment 1 or 2, the working fluid from the high-pressure heater is connected to the tail economizer of the coal-fired boiler through a feed water pump, and another All the way is introduced to the heating surface of the waste heat furnace through the feed water pump, and the unsaturated water coming out of the heating surface is combined with the water from the high-pressure heater through the pipeline, and then introduced to the economizer inlet of the coal-fired boiler.

[0018] As a further improvement of the present invention, the high-pressure unsaturated water of the body of the garbage incinerator is connected to the heating surface of the waste heat furnace of the garbage incinerator through a pipeline. With such a setting, the high-pressure unsaturated water produced by the garbage incineration body of the gar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com