A low-pressure cylinder-cutting-cylinder heating unit with low-addition heat recovery system

A heat supply unit and heat recovery system technology, applied in steam recovery, mechanical equipment, steam engine devices, etc., can solve the problems of large heater extraction, large heater heat load, large subcooling degree, etc., to ensure the removal Oxygen capacity, increase outlet water temperature, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

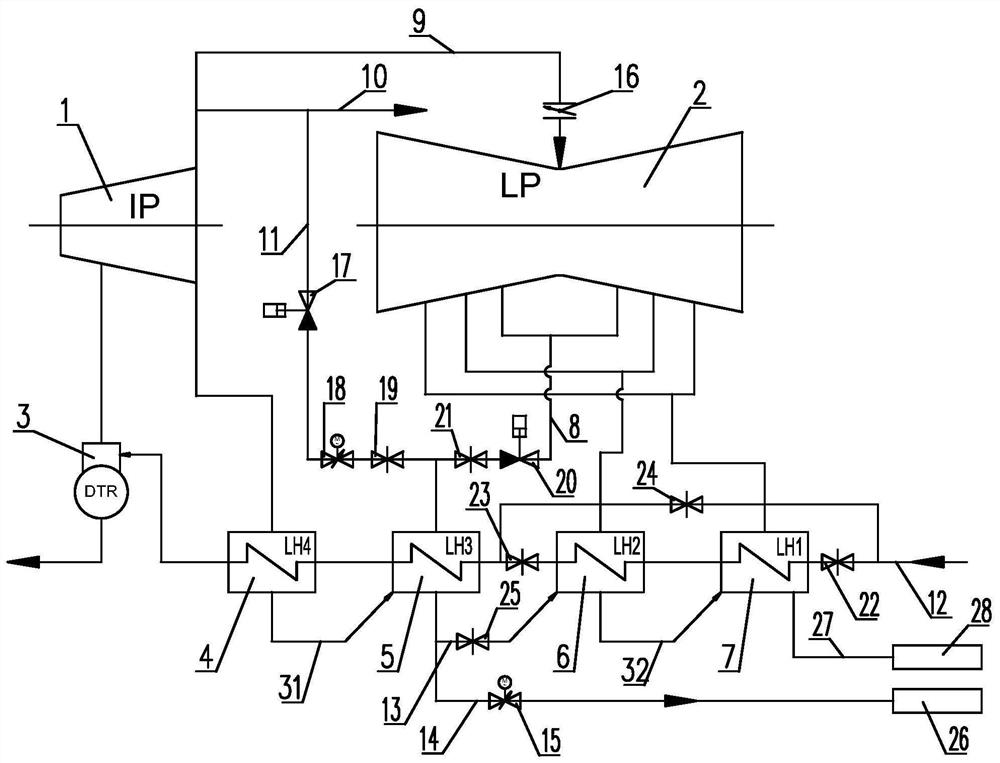

[0050] This example is figure 1 As shown: this embodiment provides a low-pressure regenerative heating system for a low-pressure cylinder 2-cylinder heating unit. When the unit is running in a pure condensing condition, the heating butterfly valve 16 is opened, and the heating extraction steam regenerative check valve is closed. 17 and heat supply extraction steam return heat shut-off valve 19; open extraction steam extraction check valve 20, extraction steam shut-off valve 21; open bypass inlet shut-off valve 22 and bypass outlet shut-off valve 23, close the bypass valve 24. The condensed water flows through the low plus one 7, the low plus two 6, the low plus three 5, and the low plus four 4 into the deaerator 3 for thermal deoxygenation; open the drain isolation valve 25, close the drain control valve 15; 4. Low-adding three-5, low-adding two-6, low-adding-one 7 Drains flow through the drain pipeline step by step, and the drains are discharged into the condenser 28; the ope...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, except that the heating butterfly valve 16 is partially opened when the unit is running under the heating condition.

Embodiment 3

[0054] This embodiment is basically as figure 1 As shown: This embodiment provides a low-pressure regenerative heating system for a low-pressure cylinder 2-cylinder heating unit. When the unit is in the switching-cylinder heating condition, the heating butterfly valve 16 is closed to achieve cylinder switching, and the steam extraction check valve is closed. 20. The extraction steam shut-off valve 21 cuts off the extraction steam source of the low-pressure cylinder 2 of the low-pressure cylinder 2; The steam is introduced into the low-heat 3-5 to exchange heat with the condensed water to heat the condensed water; at the same time, the heating extraction steam recovery control valve 18 is opened to adjust the extraction steam pressure to maintain a reasonable interstage pressure difference between the low-add 3-5 and the low-add 4-4. At the same time, close the drain isolation valve 25, open the drain regulating valve 15 for draining; close the bypass inlet shut-off valve 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com