A superheated steam temperature adjustment system and method suitable for scr low load operation

A superheated steam temperature, low load technology, applied in the direction of superheated temperature control, steam superheating, preheating, etc., can solve the problems of being unable to put into operation, and achieve saving of environmental protection expenses, reduction of investment costs, system transformation and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

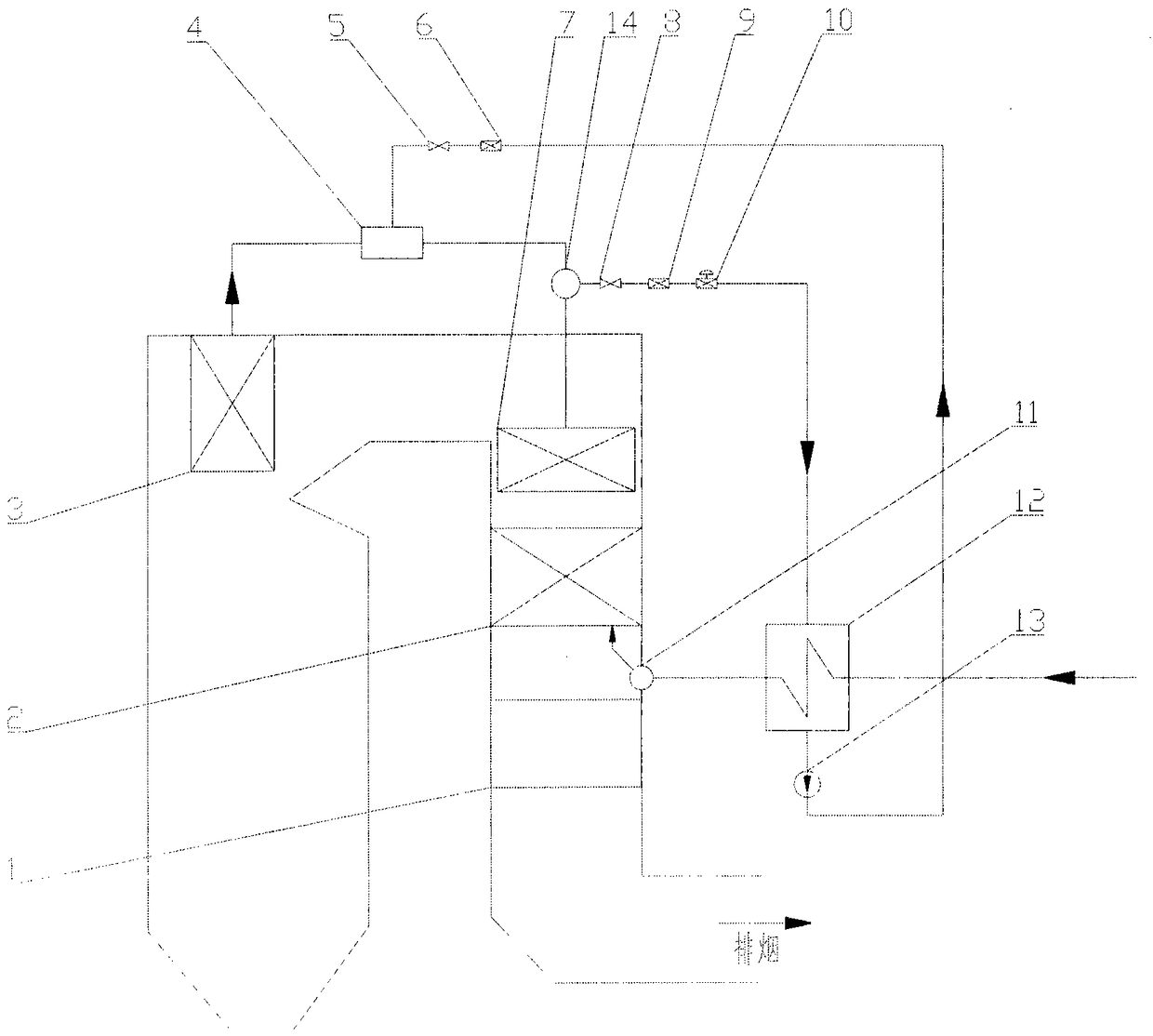

[0020] Such as figure 1 As shown, a superheated steam temperature adjustment system suitable for SCR low load operation, including SCR denitrification system 1, economizer 2, panel superheater 3 and steam bypass system, the panel superheater 3 Installed on the top of the exhaust flue of the boiler, the SCR denitrification system 1 is installed on the outlet side of the exhaust flue of the boiler, the economizer 2 is installed at the front end of the SCR denitrification system 1, and the front end of the economizer 2 A low-temperature superheater 7 is installed; the steam bypass system includes the first-stage spray desuperheater 4, the outlet header 14 of the low-temperature superheater, and the outlet header 14 connected between the first-stage spray desuperheater and the outlet header of the low-temperature superheater One end of the first-stage spray desuperheater 4 communicates with the panel superheater 3, and the other end of the first-stage spray desuperheater 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com