A kind of anti-collapse and high-strength composite calcium phosphate bone cement and its preparation method and application

A calcium phosphate bone cement, high-strength technology, used in prosthesis, tissue regeneration, medical science and other directions, can solve the problems of self-curing or collapse, and achieve good application prospects, good clinical application effects, and prolong the effect of curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of calcium phosphate cement

[0043] Dissolve Dopa-CS (grafting rate 10%) in 0.1M citric acid solution to make 0.5% Dopa-CS solution, then mix Dopa-CS solution with 1g Calcium phosphate bone cement powder (α-tricalcium phosphate-calcium hydrogen phosphate-calcium carbonate) was uniformly mixed, reconciled into a paste, injected into the mold and tested.

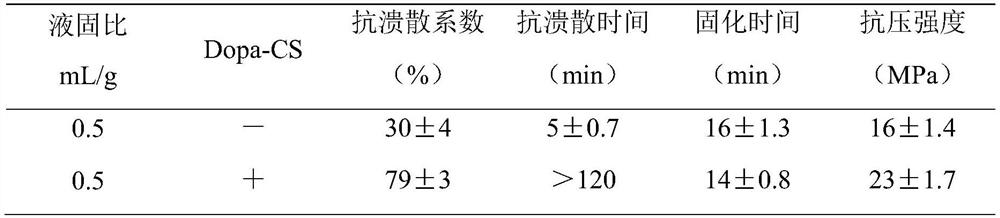

[0044] 2. Physical and chemical performance testing

[0045] The physical and chemical properties of the bone cement prepared in step 1 and those without Dopa-CS were tested.

[0046] (1) Curing time test

[0047] The cure time test was performed according to the American Society for Testing and Materials standard ASTM C190-03. The weight of the indenter of the Vicat instrument used is 300±0.5g, and the diameter of the needle is 1±0.05mm. The test steps are as follows: Fill the above-mentioned blended paste into a φ8mm×12mm cylindrical mold to form it, and put it in a constant temperature and humidit...

Embodiment 2

[0058] Dissolve Dopa-CS (grafting rate 7%) in 0.1M citric acid solution to make 1% Dopa-CS solution, then mix Dopa-CS solution with 1g Calcium phosphate bone cement powder (α-tricalcium phosphate-calcium dihydrogen phosphate-calcium carbonate) was evenly mixed, reconciled into a paste, injected into the mold and tested. The detection method and steps are the same as in Example 1.

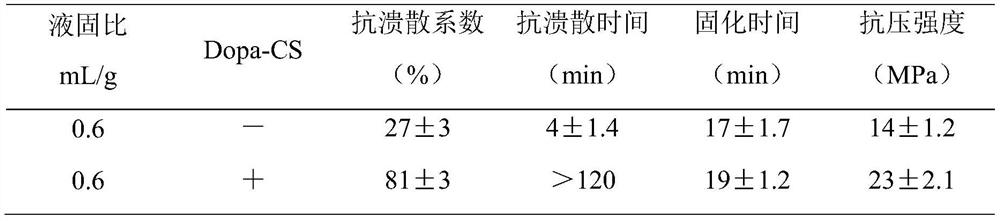

[0059] The physical and chemical properties of the anti-collapse and high-strength calcium phosphate bone cement containing Dopa-CS prepared in this example and ordinary α-tricalcium phosphate-calcium dihydrogen phosphate-calcium carbonate bone cement are shown in Table 2:

[0060] Table 2 physical and chemical properties

[0061]

[0062] Compared with ordinary calcium phosphate bone cement, the anti-collapse and high-strength calcium phosphate bone cement containing Dopa-CS prepared in this example has an anti-collapse coefficient of 81±3%, and the anti-collapse time is also increased to more ...

Embodiment 3

[0064] Dissolve Dopa-CS (grafting rate 10%) in 0.1M citric acid solution to make 2% Dopa-CS solution, then mix Dopa-CS solution with 1g Calcium phosphate bone cement powder (α-tricalcium phosphate-calcium dihydrogen phosphate-calcium carbonate) was evenly mixed, reconciled into a paste, injected into the mold and tested. The detection method and steps are the same as in Example 1.

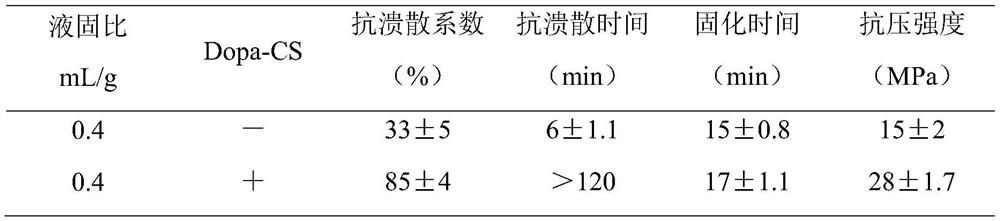

[0065] The physical and chemical properties of the anti-collapse and high-strength calcium phosphate bone cement containing Dopa-CS prepared in this example and ordinary α-tricalcium phosphate-calcium dihydrogen phosphate-calcium carbonate bone cement are shown in Table 3:

[0066] Table 3 physical and chemical properties

[0067]

[0068] Compared with ordinary calcium phosphate bone cement, the anti-collapse and high-strength calcium phosphate bone cement containing Dopa-CS prepared in this example has an anti-collapse coefficient of 85±4%, and the anti-collapse time is also increased to more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com