Biochar composite photocatalytic material preparation method

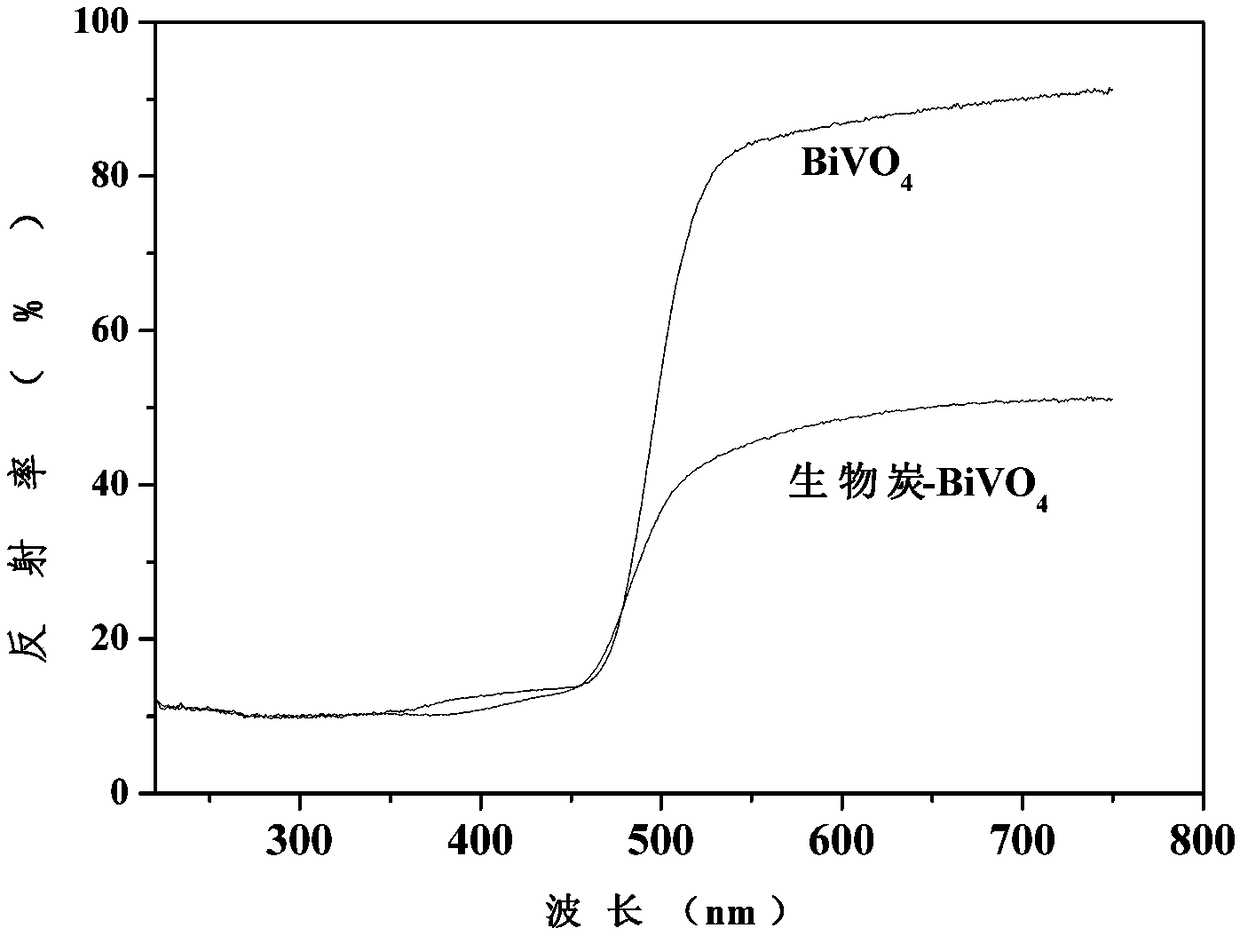

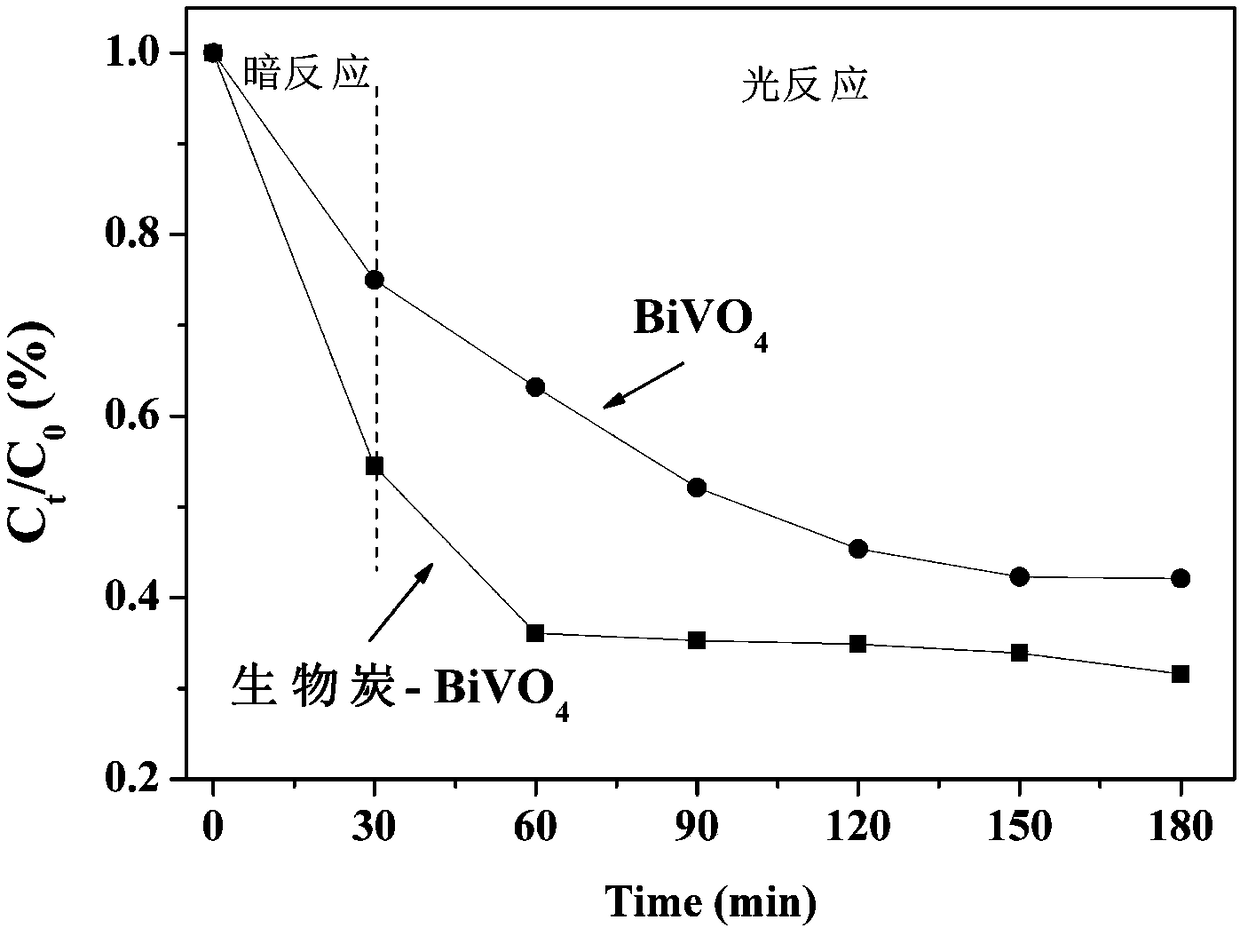

A technology of composite photocatalysis and biochar, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as few research concerns, and achieve cheap sources Easy to obtain, strengthen adsorption, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0049] Case 1:

[0050] Biochar of the present invention-BiVO 4 The preparation method of composite photocatalytic material comprises the following steps:

[0051] 1) Wash the fresh elephant grass with tap water to remove surface impurities (the raw material used in this study comes from the elephant grass in the net room of South China Agricultural University), dry it in the sun, put it in an oven at 60°C and dry it fully, then crush it with a pulverizer, and use it as a raw material for later use;

[0052] 2) Weigh 15g of raw material, fill it in a closed stainless steel thick-walled container, put it into a programmed temperature-controlled muffle furnace, and heat it at 15°C min -1 Raise the temperature to 650°C, then carbonize at a constant temperature for 3 hours, cool down to room temperature naturally, grind the powder and pass through a 100 sieve to obtain the primary product of biochar;

[0053] 3) Treat the primary product of biochar in step 2) with a 1:1 HCl solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com