High-temperature resistant erosion-resistant carbon fiber composite tube and preparation method thereof

A composite material pipe and composite material technology, applied in the field of high temperature and erosion resistant carbon fiber composite material pipe and its preparation, can solve the problems of heavy weight, weak resistance to deformation and damage, and low temperature resistance, and achieve light weight, The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] On the other hand, the present invention also provides a method for preparing the above-mentioned high-temperature and erosion-resistant carbon fiber composite material pipe, including:

[0043] Step 1: Preparation of the ablation-resistant layer: impregnate two-dimensional or three-dimensional woven carbon fiber fabrics with resin, and carbonize the resin after multiple impregnations in an inert gas environment to form a carbon matrix;

[0044] Step 2: Preparation of the erosion-resistant layer: the surface of the ablation-resistant layer obtained in step 1 is prepared by using a carbon fiber two-dimensional fabric laminate structure or a three-dimensional fabric structure preform, impregnating the ceramic matrix with the prefabricated fabric, and then sintering in a high temperature environment to form For ceramic matrix composite materials, the entire sintering process is carried out in an inert gas environment or a vacuum environment;

[0045] Alternatively, the sur...

Embodiment 1

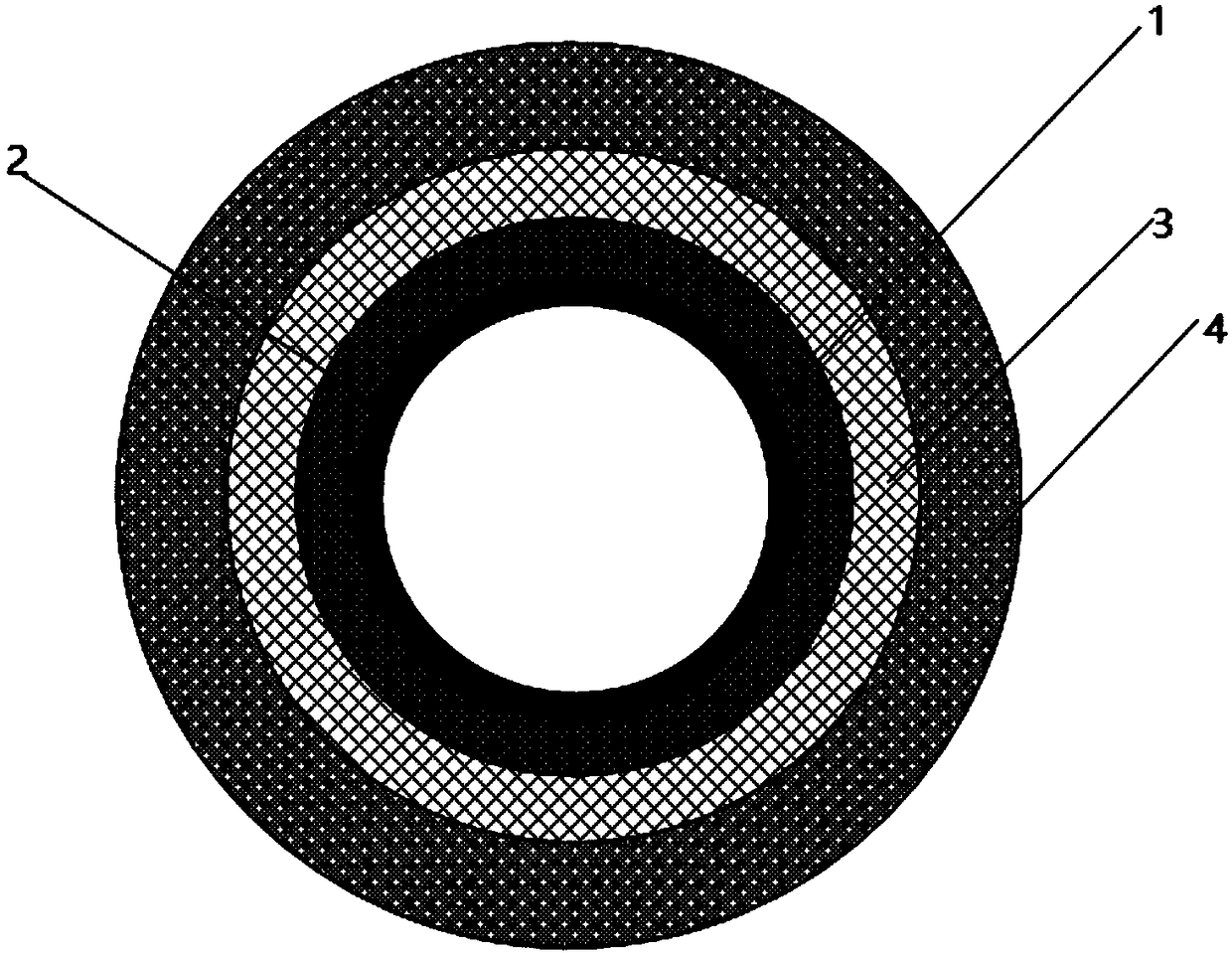

[0053] The carbon fiber high-temperature and erosion-resistant tubular structure is composed of four layers: ablation-resistant layer, erosion-resistant layer, high-temperature strength layer, and insulation layer. The ablation-resistant layer is made of phenolic resin impregnated with three-dimensional four-way woven T300 carbon fiber fabric. Sub-immersion carbonization, the carbonization temperature is 2000°C, the final carbon matrix content is 40%, the porosity is controlled at 0.1%, and the bulk density of the overall ablation-resistant layer is 1.8g / cm 3 ; After the ablation-resistant layer is prepared, use T800 carbon fiber two-dimensional laminated structure fabric on its surface to reinforce silicon nitride ceramics to prepare a composite material, in which the content of the ceramic matrix is finally controlled at 50%, and the entire preparation is sintered at high temperature in a vacuum environment , the sintering temperature is 1700°C; on the surface of the erosio...

Embodiment 2

[0055] The carbon fiber high-temperature and erosion-resistant tubular structure is composed of four layers: ablation-resistant layer, erosion-resistant layer, high-temperature strength layer, and insulation layer. The ablation-resistant layer is made of furan resin impregnated with three-dimensional four-way woven T800 carbon fiber fabric. Sub-immersion carbonization, the carbonization temperature is 1800°C, the final carbon matrix content is 42%, the porosity is controlled at 0.2%, and the bulk density of the overall ablation-resistant layer is 1.8g / cm 3 ; After the ablation-resistant layer is prepared, the composite material is prepared by using T700 carbon fiber two-dimensional laminated structure fabric to reinforce silicon carbide ceramics on its surface, wherein the content of the silicon carbide matrix is finally controlled at 40%, and the entire preparation is sintered at high temperature in a vacuum environment , the sintering temperature is 1800°C; on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com