A kind of sealing material and construction method for covering disposal of coal gangue hill

A technology of sealing materials and construction methods, applied in landfill technology, solid waste removal, etc., can solve problems such as soil pollution, low strength level, and short service life, and achieve long service life, good sealing performance, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

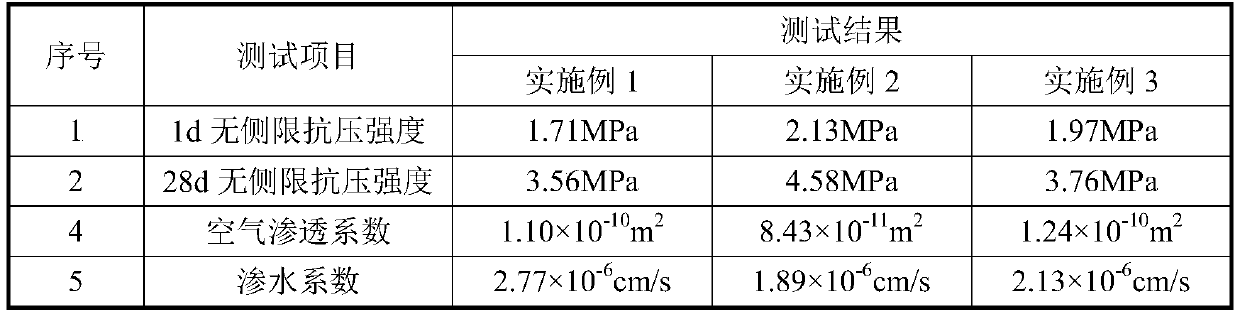

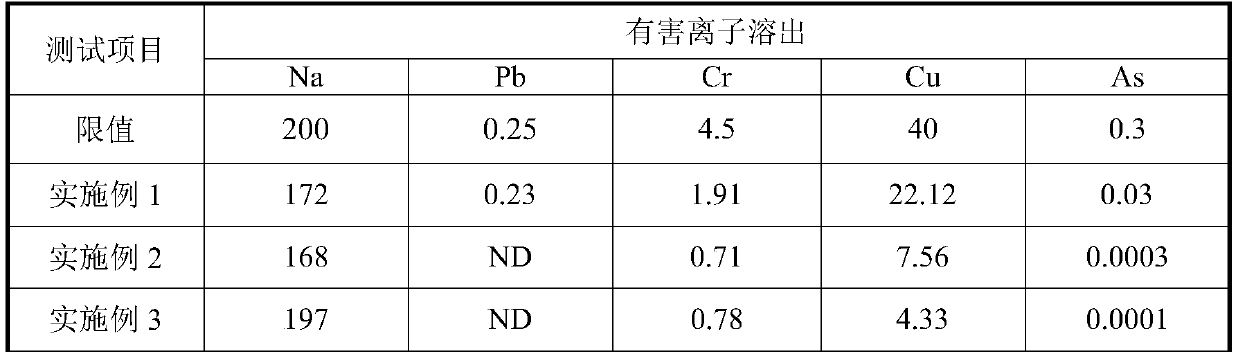

Embodiment 1

[0030] This embodiment provides a red mud fly ash sealing cementitious material, the raw materials are: red mud 500kg, fly ash 400kg, desulfurization gypsum 50kg, lime 50kg, activator 5kg, ion curing agent 2.5kg, the required water volume is 275kg .

[0031]Among them, the composition and content of the activator are respectively: 30% of polyaluminum chloride, 15% of sodium hydroxide, 15% of sodium silicate, and 40% of cement. The composition and content of the ion curing agent are respectively 50% of layered double hydroxide and 50% of ammonium chloride. Layered double hydroxides are C-LDHs, specifically Mg-Al-CO 3 Type or Ca-Al-CO 3 Type LDHs were calcined at 500°C and then cooled to room temperature.

[0032] The preparation steps of the red mud fly ash sealing cementitious material are as follows:

[0033] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0034] b. Add the admixture to the water and stir thoroughly.

[...

Embodiment 2

[0038] This embodiment provides a red mud fly ash sealing cementitious material, raw materials are: red mud 550kg, fly ash 315kg, desulfurization gypsum 60kg, lime 75kg, activator 7.5kg, ion curing agent 5kg, the required water volume is 282kg .

[0039] Among them, the composition and content of the activator are respectively: 30% of polyaluminum sulfate, 20% of sodium hydroxide, 10% of sodium silicate, and 40% of cement. The composition and content of the ion curing agent are 60% of layered double hydroxide and 40% of ammonium chloride.

[0040] The preparation steps of the red mud fly ash sealing cementitious material are as follows:

[0041] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0042] b. Add the admixture to the water and stir well.

[0043] c. Add the well-mixed aqueous solution into the evenly mixed dry material according to the proportion, and then fully stir evenly.

[0044] This embodiment also provides ...

Embodiment 3

[0046] This embodiment provides a red mud fly ash sealing cementitious material, raw materials are: red mud 600kg, fly ash 225kg, desulfurization gypsum 75kg, lime 100kg, activator 10kg, ion curing agent 7.5kg, the required water volume is 297kg .

[0047] Among them, the composition and content of the activator are respectively: 35% of polyaluminum chloride, 15% of sodium hydroxide, 15% of sodium silicate, and 35% of cement. The composition and content of the ion curing agent are respectively 50% of layered double hydroxide and 50% of ammonium chloride.

[0048] The preparation steps of the red mud fly ash sealing cementitious material are as follows:

[0049] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0050] b. Add the admixture to the water and stir well.

[0051] c. Add the well-mixed aqueous solution into the evenly mixed dry material according to the proportion, and then fully stir evenly.

[0052] This embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com