A kind of organic titanium crosslinking agent and its preparation method and application

A technology of cross-linking agent and organic titanium, which is applied in the field of organic titanium cross-linking agent and its preparation, can solve the problems of cross-linking influence of boron component, uncontrollable cross-linking, large influence of cross-linking, etc., to achieve shielding cross-linking reaction, Strong sand-carrying performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of an organic titanium crosslinking agent, comprising the following steps:

[0021] Under airtight conditions, tetraisopropyl titanate, sodium gluconate, glycerin and triethanolamine are mixed for a complexation reaction to obtain a complexation liquid;

[0022] The complex solution is mixed with water to obtain the organic titanium crosslinking agent.

[0023] In the invention, under airtight conditions, tetraisopropyl titanate, sodium gluconate, glycerin and triethanolamine are mixed for complexation reaction to obtain complexation liquid. In the present invention, the mass ratio of tetraisopropyl titanate, sodium gluconate, glycerol and triethanolamine is preferably 2.5-5.0:0.05-0.1:10-50:5-10, more preferably 3-4.5: 0.06~0.1:20~40:6~8.

[0024] In the present invention, the temperature of the complexation reaction is preferably 60-80°C, more preferably 70-75°C, and the time of the complexation reaction is preferably 60-1...

Embodiment 1

[0036] At room temperature, add tetraisopropyl titanate, sodium gluconate, glycerin, and triethanolamine into the flask in sequence according to the following ratio (weight ratio) = 2.5:0.05:10:5, and then put the flask into 60 In the constant temperature device at ℃, stir the materials in the flask under airtight conditions for 60 minutes. After the complexation reaction is complete, the complexation liquid turns yellow. Add pure water with the total weight of the complexing solution into the flask, and stir for 60 min at a temperature of 60°C. After the stirring is completed, a light yellow transparent organotitanium crosslinking agent is obtained.

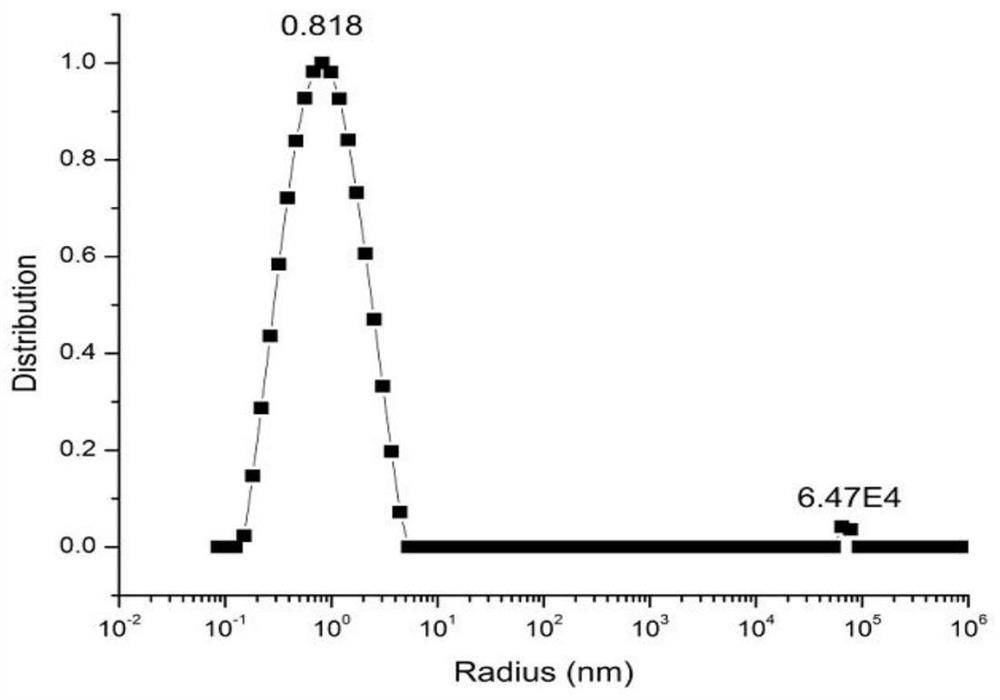

[0037] The organotitanium crosslinking agent prepared in the present embodiment is analyzed for particle size, and the results are as follows: figure 1 shown by figure 1 It can be seen that the diameter of the organotitanium crosslinking agent prepared in this embodiment is 10 -1 The mass content of the small-sized titanium co...

Embodiment 2

[0040]At room temperature, add tetraisopropyl titanate, sodium gluconate, glycerin, and triethanolamine into the flask in sequence according to the following ratio (weight ratio) = 5:0.1:50:1, and then put the flask into 80 In the constant temperature device at ℃, stir the materials in the flask under airtight conditions for 120 minutes. After the complexation reaction is complete, the complexation liquid turns yellow. Add pure water with the total weight of the complexing solution into the flask, and stir for 60 min at a temperature of 60°C. After the stirring is completed, a light yellow transparent organotitanium crosslinking agent is obtained.

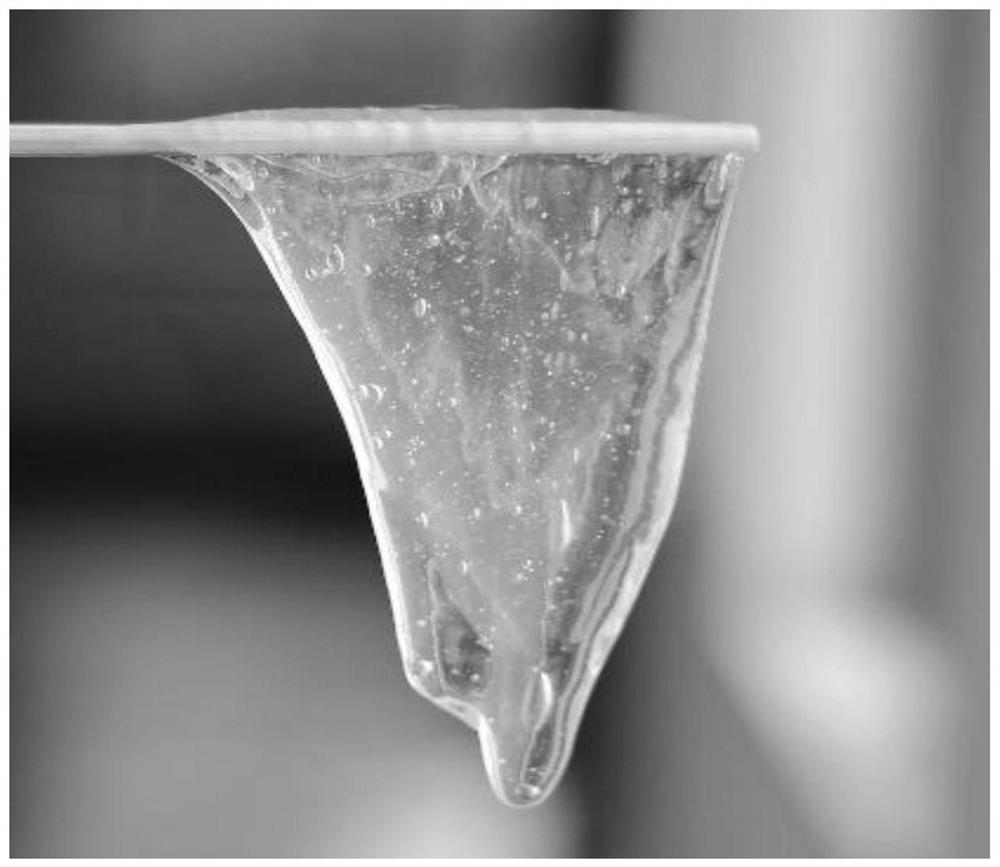

[0041] The organic titanium crosslinking agent prepared in this example is used in the fracturing fluid system for natural gas well gas production sewage, the volume ratio of organic titanium crosslinking agent and natural gas well gas production sewage base fluid system is 0.4-0.5%, The connection time is about 2 minutes, and can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com