Energy saving and environment protecting system for changing thermal-chemical bond energy

An energy-saving, environmentally friendly, thermochemical technology, applied in the field of thermochemistry, can solve the problems of thermal combustion waste, small release enthalpy, and low thermochemical reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

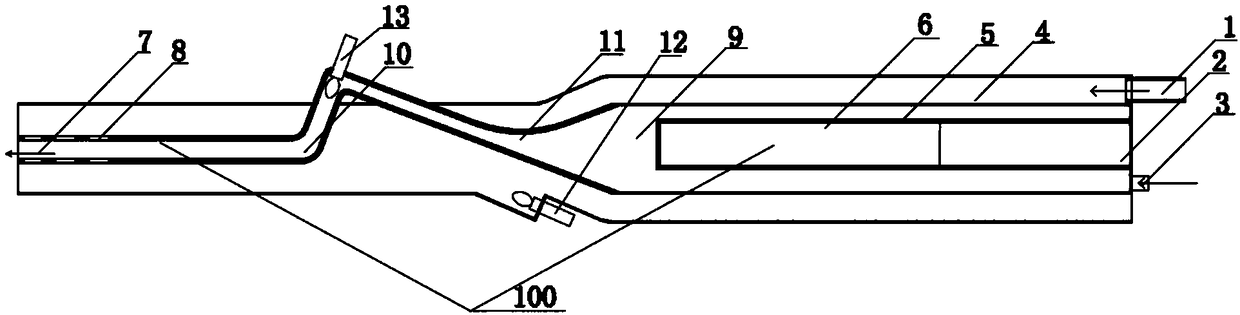

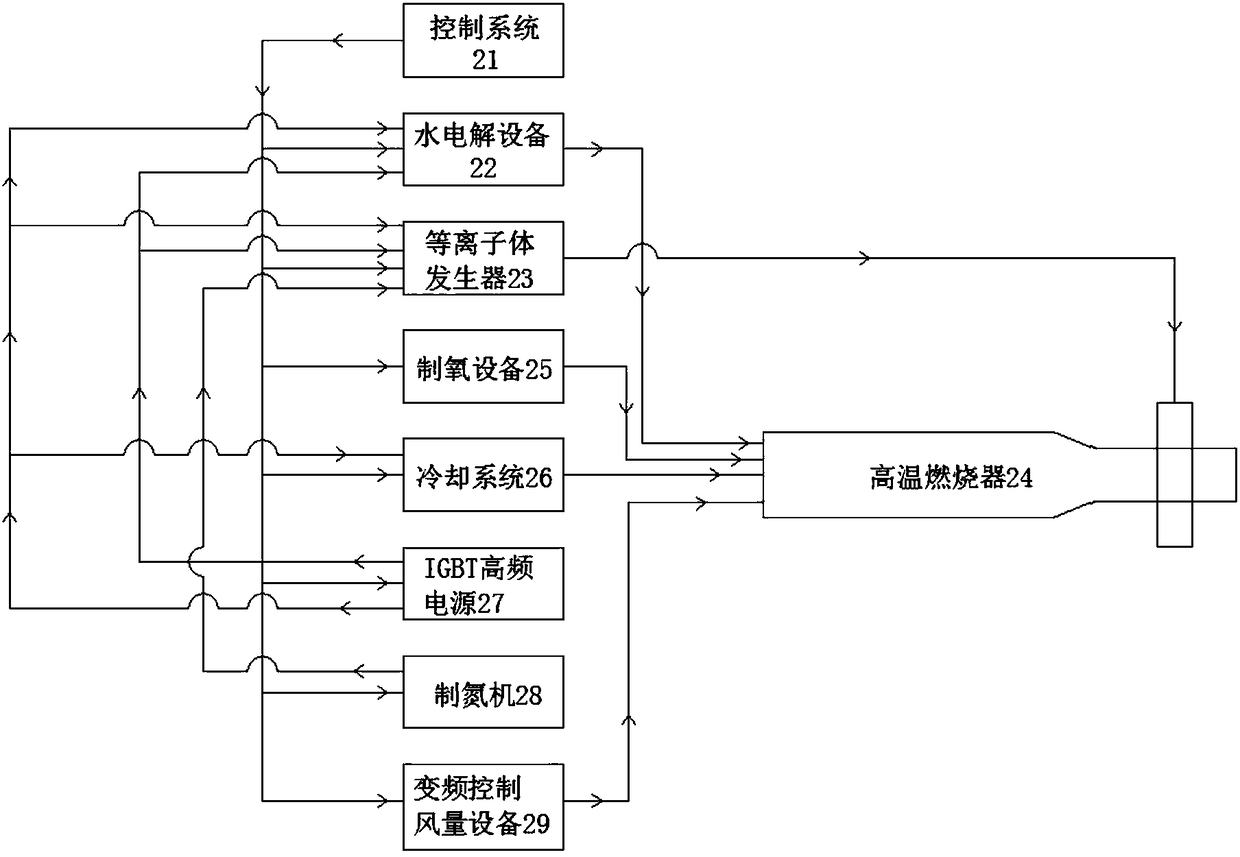

[0037] refer to figure 2 As shown, an energy-saving and environment-friendly system for changing thermochemical bond energy includes: a control system 21, which can be a DSP control system; a high-temperature burner 24; a water electrolysis device 22, which is used to generate hydrogen and oxygen, Used to provide hydrogen and oxygen heating flames for the inner tank 6 of the high-temperature burner 24; a plasma generator 23, which is used to generate high-temperature plasma, and is used to provide a high-temperature heat source for secondary heating of oxygen and gas; Oxygen production equipment 25, this oxygen production equipment 25 is used for producing oxygen and provides oxygen for the outer bladder 4 of high temperature burner 24; Cooling system 26, this cooling system 26 is used for high temperature burner 24, water electrolysis equipment 22, plasma generation 23, oxygen generator 25 and high-temperature burner 24 for cooling; IGBT high-frequency power supply 27, the I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com