A method and product for preparing ceramic brick embryos by using a large amount of waste squeezed mud from ceramic factories

A technology for ceramic tiles and ceramic factories, which is applied in the field of building ceramic materials, can solve problems such as environmental pollution and waste of resources, and achieve the effects of reducing costs, increasing strength, and improving molding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

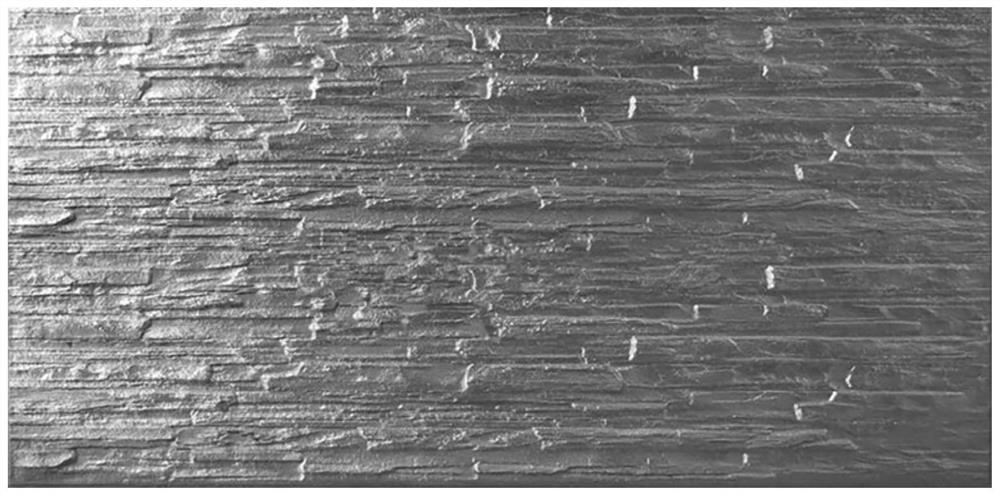

Image

Examples

Embodiment 1

[0050] A method for preparing a ceramic brick body by using waste squeezed mud from ceramic factories in large quantities, comprising the following steps:

[0051] (1) In terms of weight percentage, the following raw materials are weighed and mixed, then wet pulverized with a ball mill to become a slurry, the moisture content of the slurry is 31% to 34%, and the 250 mesh sieve balance is between 3.5% and 5%, The dynamic viscosity is between 500 and 800mpa.s (measured with NDJ-1 rotary viscometer);

[0052] The ceramic tile body includes the following raw materials:

[0053]

[0054] Described coal-water slurry slag is the slag that discharges after the coal-water slurry combustion in the hot-blast stove of producing ceramic brick, and its composition is the slag of our factory in Table 1;

[0055] (2) Spray-dry the mud after passing through an 80-mesh sieve, and then pass through a 12-mesh sieve to obtain a powdery blank with a moisture content of 6.5 to 7.0%;

[0056] (3...

Embodiment 2

[0065] A method for preparing a ceramic brick body by using waste squeezed mud from ceramic factories in large quantities, comprising the following steps:

[0066] (1) In terms of weight percentage, the following raw materials are weighed and mixed, then wet pulverized with a ball mill to become a slurry, the moisture content of the slurry is 31% to 34%, and the 250 mesh sieve balance is between 3.5% and 5%, The dynamic viscosity is between 500 and 800mpa.s (measured with NDJ-1 rotary viscometer);

[0067] The ceramic tile body includes the following raw materials:

[0068]

[0069] Described coal-water slurry slag is the slag that discharges after the coal-water slurry combustion in the hot-blast stove of producing ceramic brick, and its composition is the slag of our factory in Table 1;

[0070] (2) Spray-dry the mud after passing through an 80-mesh sieve, and then pass through a 12-mesh sieve to obtain a powdery blank with a moisture content of 6.5 to 7.0%;

[0071] (3...

Embodiment 3

[0076] A method for preparing a ceramic brick body by using waste squeezed mud from ceramic factories in large quantities, comprising the following steps:

[0077] (1) In terms of weight percentage, the following raw materials are weighed and mixed, then wet pulverized with a ball mill to become a slurry, the moisture content of the slurry is 31% to 34%, and the 250 mesh sieve balance is between 3.5% and 5%, The dynamic viscosity is between 500 and 800mpa.s;

[0078] The ceramic tile body includes the following raw materials:

[0079]

[0080] Described coal-water slurry slag is the slag that discharges after the coal-water slurry combustion in the hot-blast stove of producing ceramic brick, and its composition is the slag of our factory in Table 1;

[0081] (2) Spray-dry the mud after passing through an 80-mesh sieve, and then pass through a 12-mesh sieve to obtain a powdery blank with a moisture content of 6.5 to 7.0%;

[0082] (3) The powdery blank is stale for more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com