Miniature flexible biological electrode array and preparation method thereof

A bio-electrode and flexible technology, applied in the field of micro-flexible bio-electrode arrays and its preparation, can solve the problems of short service life, large size, poor biological and mechanical properties of bio-electrodes, and achieve improved sensitivity, signal-to-noise ratio, anti- Effect of high tensile strength, improved biocompatibility and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example is used to illustrate the preparation of the miniature flexible bioelectrode array provided by the present invention.

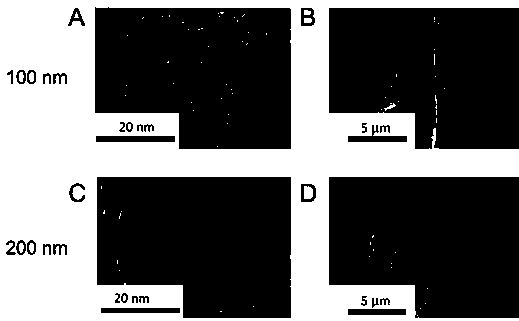

[0041] Dry by hot pressing to form a 10 μm thick cellulose film ( figure 1 A) Prepare a shadow mask of a 30-micron electrode array with a single electrode. After covering the shadow mask, vacuumize in a vacuum evaporation apparatus for 4 hours, and then coat a layer of 10 nm on the surface of bacterial cellulose at 0.1À / s. Cr, and then vapor-deposit 100nm Au on its surface at 0.1À / s for about 18 minutes. During the metal evaporation process, the thickness of the electrode deposited on the substrate can be controlled by adjusting the evaporation time. After the metal layer electrode is prepared, a layer of SiNx insulating layer is deposited on the metal surface by low-temperature PECVD and shadow mask on the surface of the metal conductive electrode. Due to the uneven heat dissipation and heat generation during the PECVD evaporation proces...

Embodiment 2

[0044] This example is used to illustrate the preparation of the miniature flexible bioelectrode array provided by the present invention.

[0045] Heat and dry to form a cellulose film with a thickness of 10 microns, and prepare a shadowmask of a 30-micron electrode array with a single electrode. After covering the shadow mask, vacuumize in a vacuum evaporation apparatus for 4 hours, and then coat the bacterial cellulose with 0.1À / s The surface is coated with a layer of 10nm Cr, and then evaporated at 0.1À / s for about 35 minutes to coat the surface with 200nm Au. During the metal evaporation process, the thickness of the electrode deposited on the substrate can be controlled by adjusting the evaporation time. After the metal layer electrode is prepared, use low-temperature PECVD and shadow mask to deposit a layer of SiNx insulating layer on the surface of the metal conductive electrode. Due to the uneven heat dissipation and heat generation during the PECVD evaporation process...

Embodiment 3

[0048] This example is used to illustrate the preparation of the miniature flexible bioelectrode array provided by the present invention.

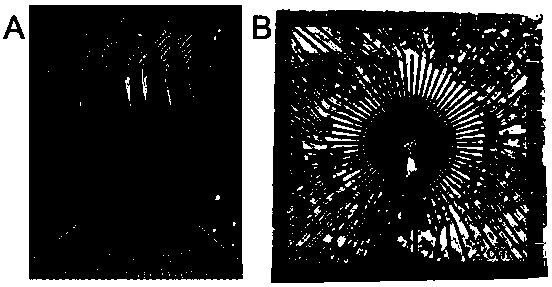

[0049] Using the method of Example 2, based on the 200nm thick Au prepared by a 10 micron film, the electrode array diagram of the implantable miniature flexible bioelectrode array prepared in the body by replacing different metal masks, including reference electrodes at both ends, and the middle 37 a working electrode array. image 3 A shows the electrode array diagram of the implantable miniature flexible bioelectrode array prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com