Preparation and application of stain-resistant coating on surface of implantable sensor

A sensor and implantable technology, applied in the field of biomedicine, can solve problems such as the decrease of electrode sensing performance and use accuracy, poor biocompatibility, and shortened sensor life, so as to solve the problem of long-term sensing performance decline and improve Biocompatibility, effect of inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

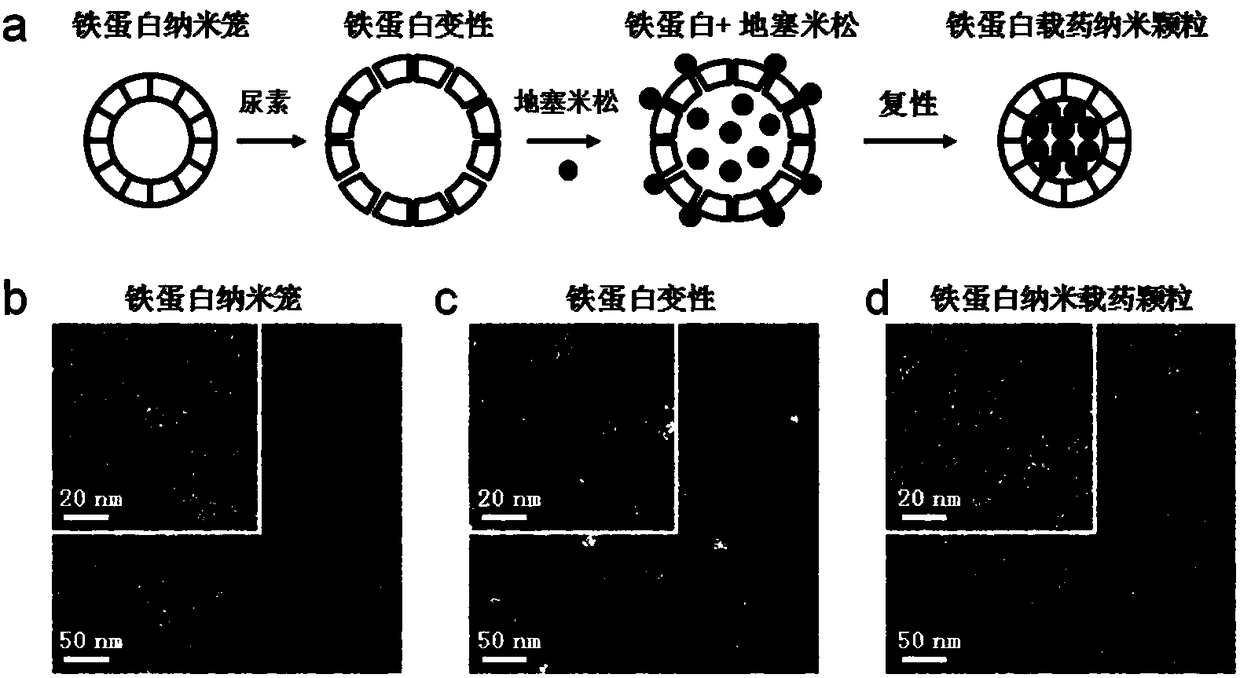

[0030] Example 1 Preparation of ferritin nano drug-loaded particles

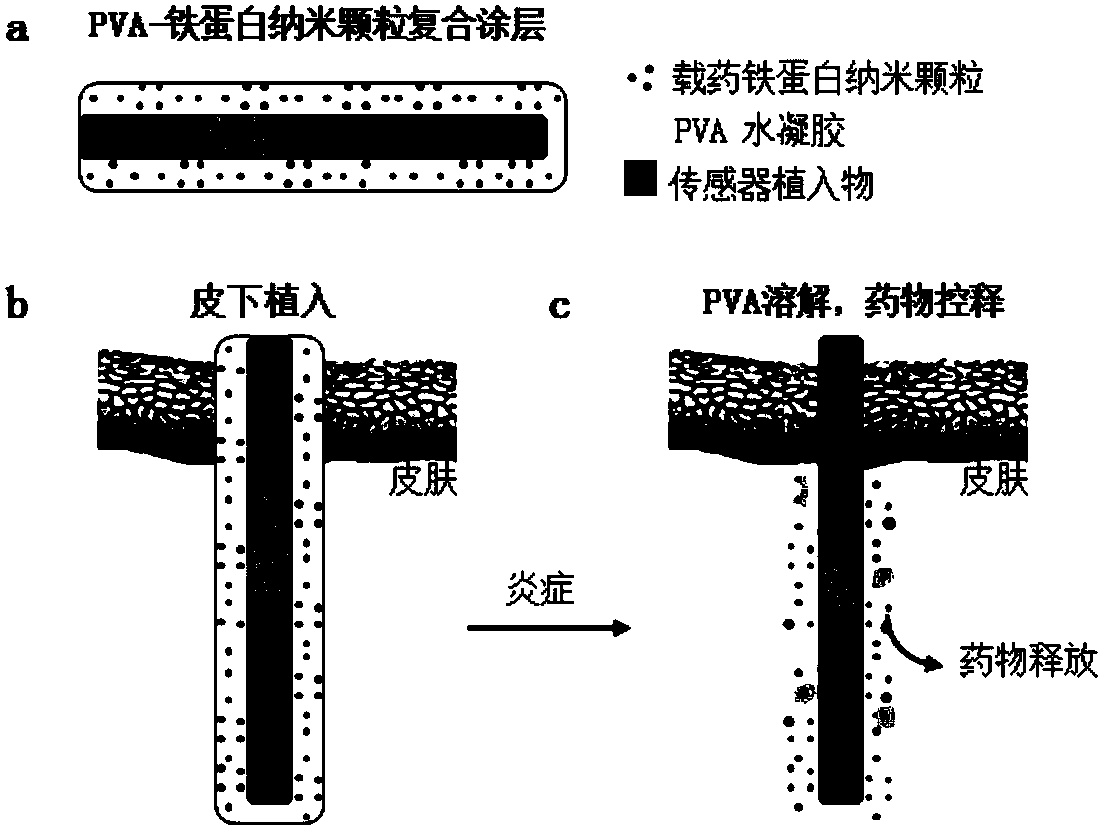

[0031] In this example, using the denaturation-refolding process of ferritin, dexamethasone (abbreviated as Dex) drug molecules were entrapped in ferritin nanocages to form ferritin nano drug-loaded particles (labeled as Ft-Dex NPs) , for its preparation see figure 2 a.

[0032] Dissolve ferritin at a final concentration of 1 mg / mL in 10 mL of 8M urea and mix with stirring at room temperature 25 °C for 30 min to ensure complete unfolding of ferritin. Dexamethasone (abbreviated as Dex) was added to it with a final concentration of 0.2 mg / mL. After mixing for 15 minutes, the mixture was transferred to a dialysis bag with a molecular cutoff of 3000, and dialyzed in a refrigerator at 4°C. The dialysate is urea buffer solution (7M, 5M, 3M, 2M, 1M and deionized water) containing 0.2 mg / mL drug in gradient concentration. Each gradient concentration is dialyzed for 4-6 hours, and after dialysis, it is reassembled...

Embodiment 2

[0033] Example 2 Preparation of ferritin nano drug-loaded particles and PVA hydrogel composite coating

[0034] Adding 0.1 mL of the ferritin nano drug-loaded particle solution prepared in Example 1 into 1 mL of 3.33% PVA solution by mass percentage (the final concentration of PVA is 3% (mass percentage)), the final concentration of Dex drug in the mixed solution is 0.4 mg / mL, after thorough mixing, the mixed solution of PVA and ferritin nano drug-loaded particles was coated on the surface of the sensor by wetting and coating. Put the sensor in a -20°C refrigerator for 1 hour, thaw at room temperature for 0.5 hour, and cycle like this for 5 times, forming a composite hydrogel coating of PVA and ferritin nano drug-loaded particles on the surface of the sensor (marked as PVA+Ft- Dex NPs).

[0035] If it is necessary to prepare a two-layer composite hydrogel coating, after one freeze-thaw cycle of PVA, the solution of PVA and ferritin nano drug-loaded particles is coated again,...

Embodiment 3

[0040] The physical and chemical property evaluation of embodiment 3 coating

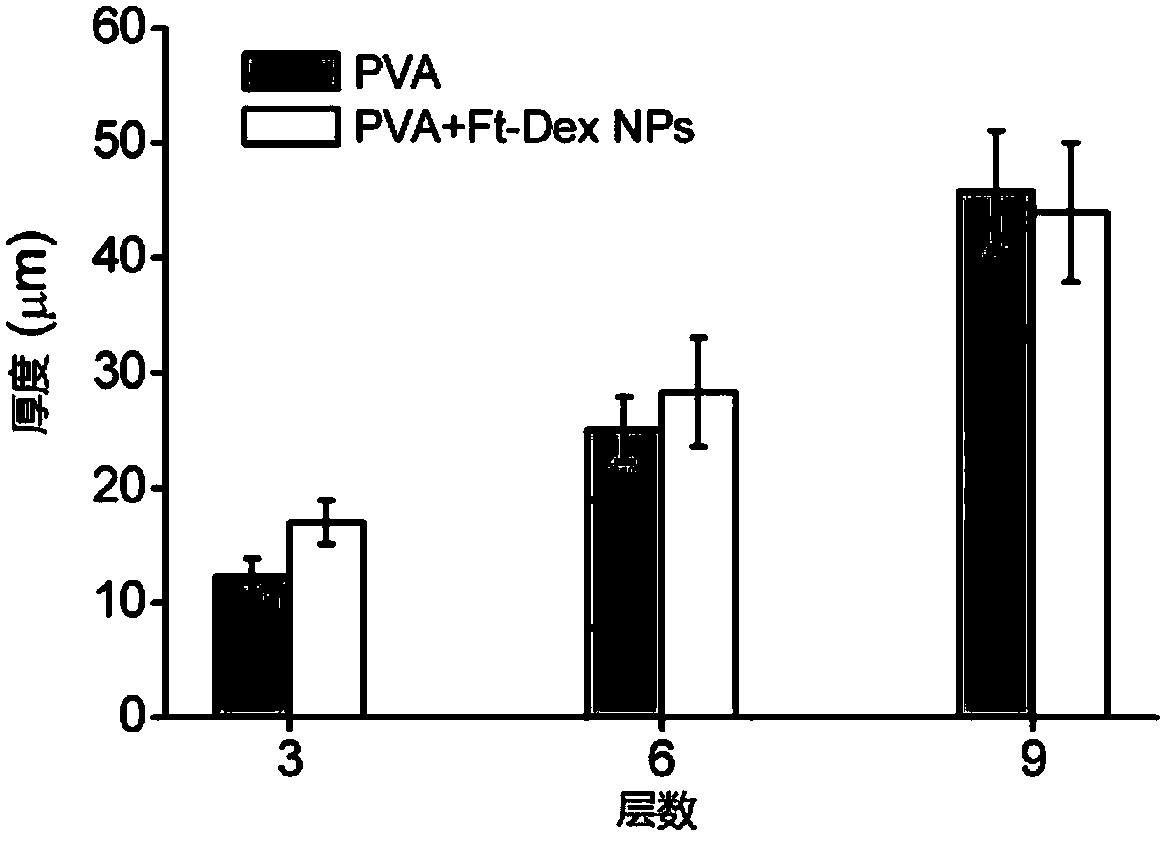

[0041] The thickness of different layers of PVA+Ft-DeX NPs composite coatings or drug-free PVA hydrogel coatings (marked as PVA) was characterized by a three-dimensional surface profiler (NanoFocus, Germany). The results are shown in image 3 . The thickness of the coating increases as the number of coating layers increases; there is no significant difference in the thickness of the PVA coating and the PVA+Ft-DeX NPs composite coating.

[0042] Using a scanning electron microscope (Zeiss Sigma, Germany) to observe the coating of the 6-layer PVA+Ft-DeX NPs composite coating or the coating of the PVA coating on the sensor, the results are shown in Figure 4 , indicating that different types of coatings can be coated on the surface of the sensor.

[0043] Utilize atomic force microscope (German JPK NanoWizard4) to observe the surface morphology of PVA+Ft-DeX NPs composite coating or PVA coating, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com