Desulfurization waste water zero discharge and white smoke purification combined treatment system

A desulfurization wastewater and combined treatment technology, which is applied in the direction of gaseous effluent wastewater treatment, gas treatment, water/sewage treatment, etc., can solve the problems of limited industrial application, high energy consumption, and low saturated humidity of ambient air to achieve high environmental protection Benefits and economic value, low energy consumption, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

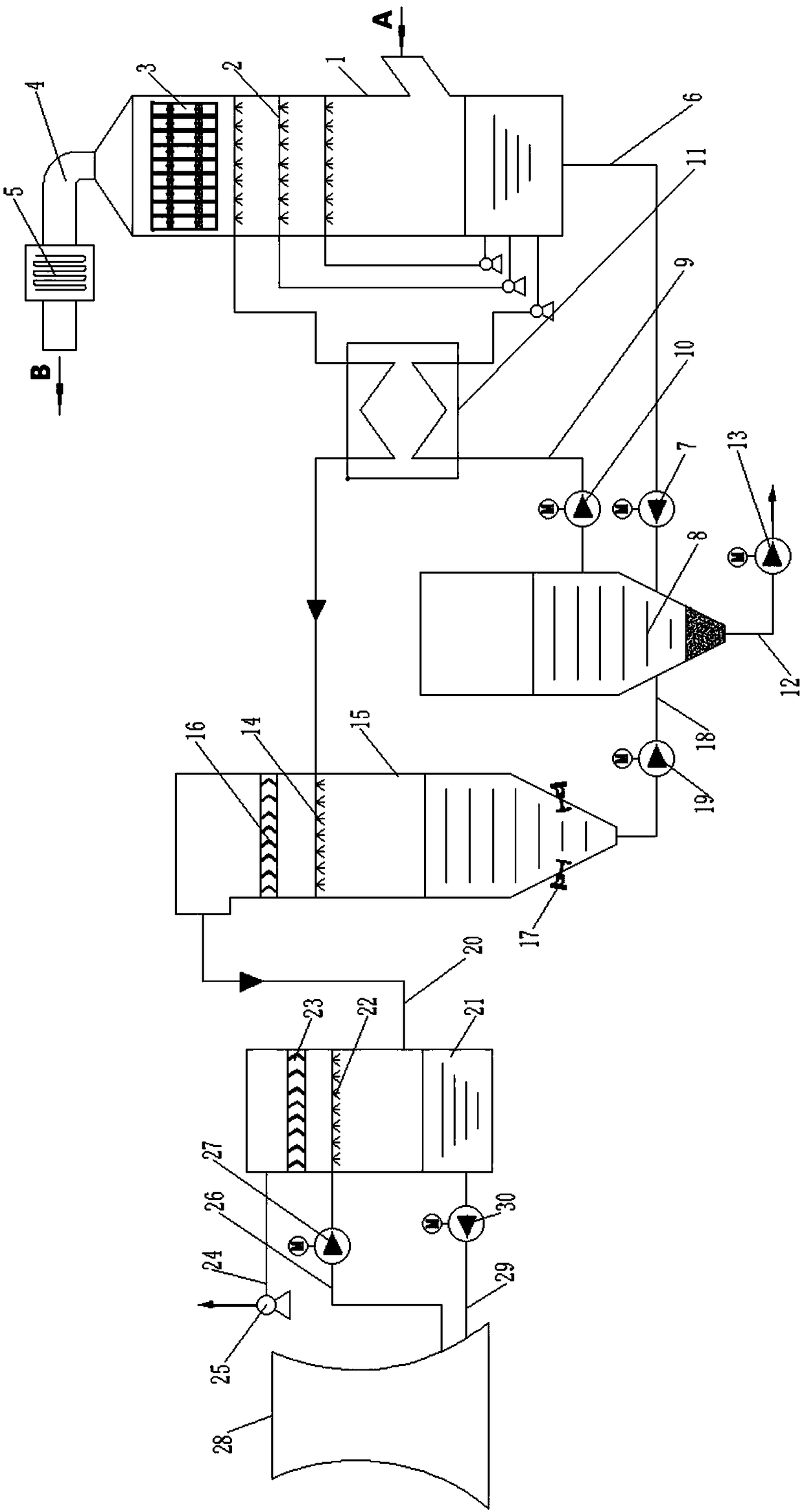

[0027] exist figure 1 Among them, the desulfurization wastewater zero discharge and flue gas dewhitening joint treatment system of the present invention includes a desulfurization tower 1, a desulfurization slurry circulation spray system 2 installed on the inner middle of the desulfurization tower, located on the upper part of the desulfurization slurry circulation spray system and installed in the desulfurization The desulfurization tower demister 3 in the tower, the desulfurization tower outlet flue 4 installed on the top of the desulfurization tower, the flue gas reheater 5 installed in the desulfurization tower outlet flue, the desulfurization wastewater discharge pipe 6 installed at the bottom of the desulfurization tower, The desulfurization wastewater discharge pump 7 installed on the desulfurization wastewater discharge pipeline, the buffer tower 8 connected to the end of the desulfurization wastewater discharge pipeline, the desulfurization wastewater clear liquid cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com