Water-based two-component in-mould coating for self-bonded polyurethane material and preparation method of water-based two-component in-mould coating

A water-based two-component, polyurethane material technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor safety, high requirements for coating products, poor flexibility of paint films, etc., to improve odor and VOC, increase product The effect of yield, excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 waterborne two-component in-mold paint

[0047] Water-based two-component in-mold paint for self-skinning polyurethane materials, its formula includes the following components, in terms of mass percentages:

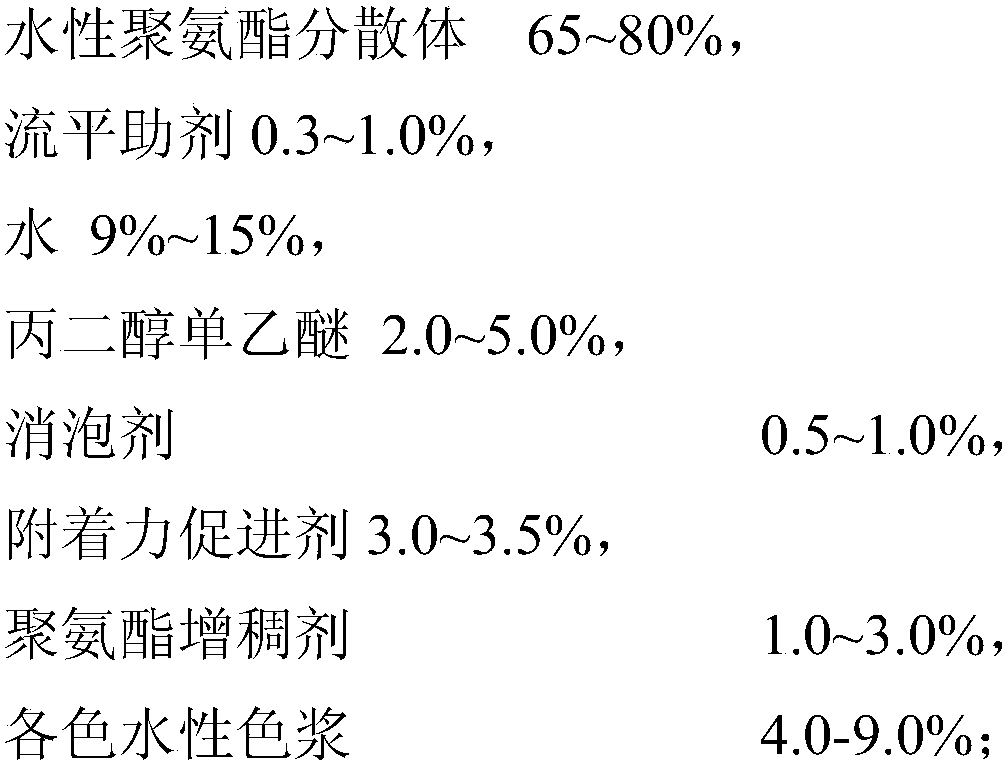

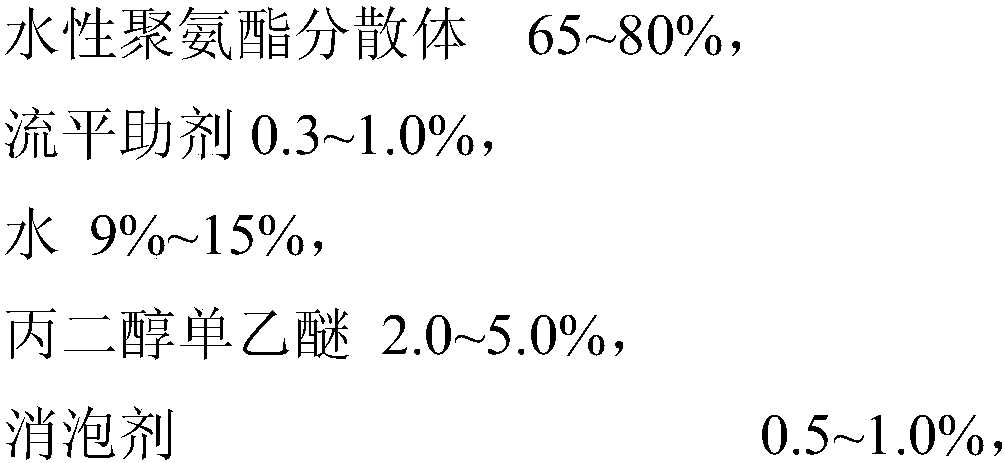

[0048] The formula of component A in-mold paint includes the following ingredients, in terms of mass percentage:

[0049]

[0050]

[0051] B component curing agent is Bayhydur 304 hydrophilic isocyanate from Covestro;

[0052] The distribution ratio of component A and group B is A:B=:100:2-20, unit mass ratio.

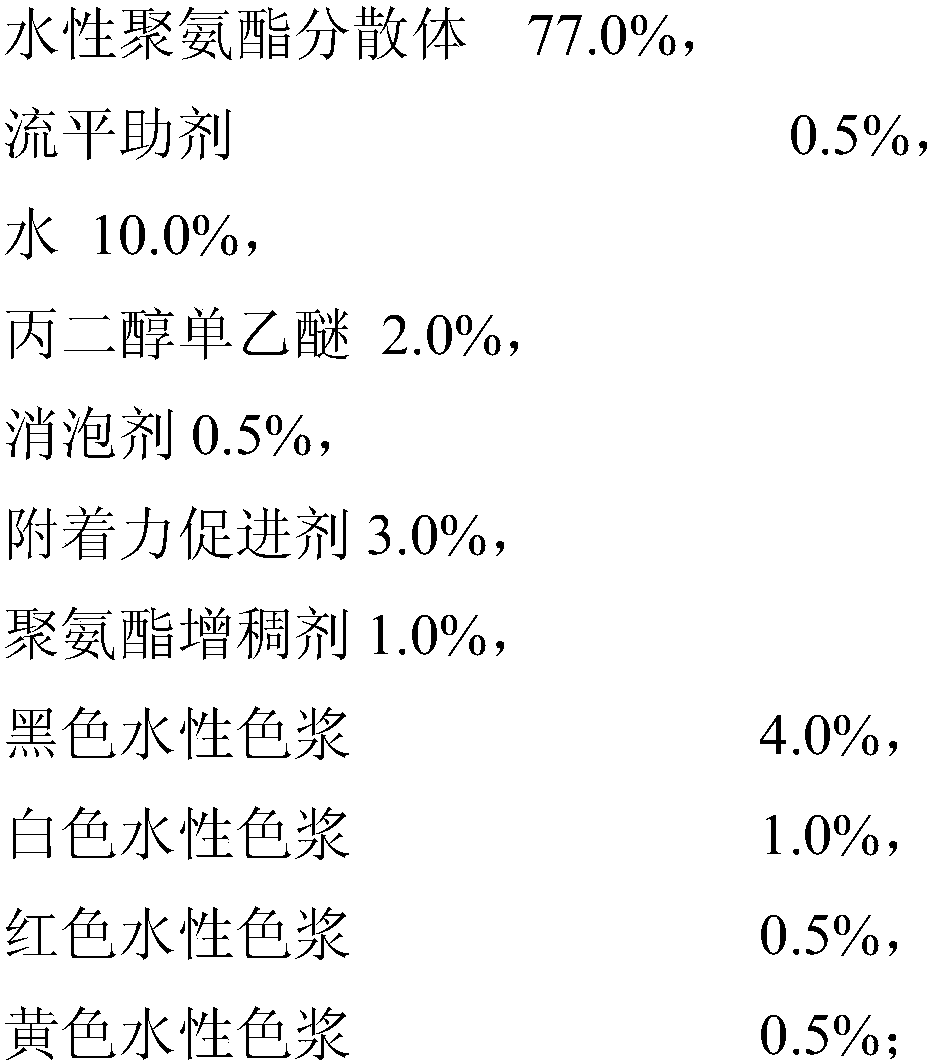

[0053] The preferred formula includes the following ingredients, and the formula of the A-component in-mold paint includes the following ingredients, according to the mass percentage of the A component:

[0054]

[0055] B component curing agent is Bayhydur 304 hydrophilic isocyanate from Covestro;

[0056] The distribution ratio of A component and B group is A:B=:, unit.

[0057] The waterborne polyurethane is ...

Embodiment 2

[0070] The detection of embodiment 2 waterborne two-component in-mold paint

[0071] Mainly investigate the technical indicators of paint film performance, according to the standard TL52045:2013 method:

[0072] (1) Environmental cycle test

[0073] (2) Thermal aging test

[0074](3) light resistance test

[0075] (4) Friction resistance test

[0076] (5)Sunshine simulation

[0077] (6) Elongation

[0078] (7) Drop test

[0079] (8) Anti-Hand Cream Face Cream

[0080] The commercially available solvent-based two-component product was used as a comparison, see Table 2.

[0081] Table 2 Detection of performance of water-based two-component in-mold paint

[0082]

[0083]

[0084] The water-based two-component in-mold paint prepared by the invention is safe, environment-friendly and has good performance.

[0085] ①Environmental protection: the content of solvent (VOC) in the product is reduced from the original (solvent) greater than 500g / l to less than 50g / l, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com