High-carbon and environment-friendly friction material for automobiles and preparation method of the high-carbon and environment-friendly friction material

A kind of friction material and environment-friendly technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc. Abnormal disc wear and other problems, to avoid the loss of braking performance, enhance wear resistance, and stabilize braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

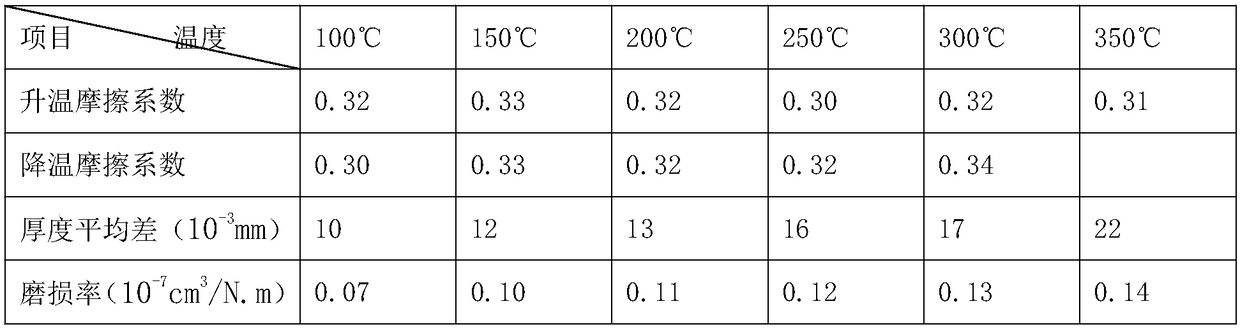

Embodiment 1

[0031] A high-carbon environment-friendly friction material for automobiles, comprising the following raw materials in parts by weight:

[0032] 2 parts of aramid fiber, 35 parts of steel wool fiber, 5 parts of zirconium silicate, 13 parts of synthetic graphite, 8 parts of modified resin, 7 parts of zinc powder, 6 parts of molybdenum disulfide, 5 parts of mica, 5 parts of friction powder, tire powder 3 parts, 4 parts of calcium hydroxide, 7 parts of barium sulfate.

[0033] The modified resin is a composite modified phenolic resin, and the specific modification process is: mix phenolic resin, boric acid, tung oil and vermiculite according to the mass ratio of 1:0.3:0.3:0.5, heat to 110°C, and ultrasonically disperse 1.5 h, then cooled to room temperature to obtain a modified resin. The friction powder is cashew nut shell oil friction powder. The length of the aramid fiber is 5 mm.

[0034] A method for preparing a high-carbon environment-friendly friction material for autom...

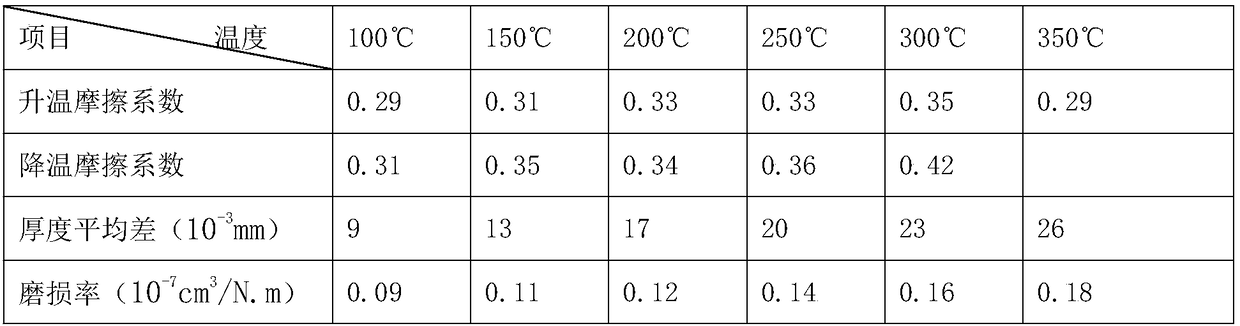

Embodiment 2

[0051] A high-carbon environment-friendly friction material for automobiles and a preparation method thereof, comprising the following raw materials in parts by weight:

[0052] 2 parts of aramid fiber, 30 parts of steel wool fiber, 5 parts of zirconium silicate, 15 parts of synthetic graphite, 10 parts of modified resin, 8 parts of zinc powder, 5 parts of molybdenum disulfide, 6 parts of mica, 5 parts of friction powder, tire powder 4 parts, calcium hydroxide 6 parts, barium sulfate 8 parts.

[0053] The modified resin is compound modified phenolic resin, and the specific modification process is: mix phenolic resin, boric acid, tung oil and vermiculite according to the mass ratio of 1:0.4:0.2:0.3, heat to 120°C, and ultrasonically disperse 2h, then cooled to room temperature to obtain modified resin. The friction powder is cashew nut shell oil friction powder. The length of the aramid fiber is 5 mm.

[0054] The preparation method is the same as in Example 1.

Embodiment 3

[0056] A high-carbon environment-friendly friction material for automobiles and a preparation method thereof, comprising the following raw materials in parts by weight:

[0057] 2 parts of aramid fiber, 32 parts of steel wool fiber, 5 parts of zirconium silicate, 15 parts of synthetic graphite, 10 parts of modified resin, 8 parts of zinc powder, 5 parts of molybdenum disulfide, 6 parts of mica, 5 parts of friction powder, tire powder 4 parts, calcium hydroxide 6 parts, barium sulfate 8 parts.

[0058] The modified resin is compound modified phenolic resin, and the specific modification process is: mix phenolic resin, boric acid, tung oil and vermiculite according to the mass ratio of 1:0.4:0.2:0.3, heat to 120°C, and ultrasonically disperse 2h, then cooled to room temperature to obtain modified resin. The friction powder is cashew nut shell oil friction powder. The length of the aramid fiber is 5 mm.

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com