A kind of silicon oxide carbon composite negative electrode material, its preparation method and lithium ion battery

A negative electrode material and composite material technology, which is applied to the silicon oxide carbon composite negative electrode material, its preparation method and the field of lithium-ion batteries, can solve the problems of high cost, high preparation cost, and the combination of silicon oxide particles and one-dimensional nanomaterials, and achieve The effect of low cost and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a silicon oxide carbon composite negative electrode material, comprising the following steps:

[0034] a) heating silicon oxide to a first temperature under an inert atmosphere, adjusting the flow rate of the inert gas, and keeping it warm to obtain a silicon oxide composite material connected by silicon nanowires; the first temperature is 800°C to 1300°C; the inert gas The flow rate is 0sccm~800sccm;

[0035] b) adjusting the silicon oxide composite material connected by silicon nanowires obtained in step a) to a second temperature, and under the condition of feeding an inert gas, feeding a carbon source gas to carry out chemical vapor deposition, and obtaining a silicon oxide carbon composite negative electrode after cooling Material; the second temperature is 600°C to 1000°C.

[0036] In the present invention, the temperature of silicon oxide is raised to the first temperature in an inert atmosphere, the flow rate of the...

Embodiment 1

[0065] Put 1.5 g of commercial silicon monoxide (SiO) with a particle size of 5 μm in an atmosphere furnace, repeatedly pump out gas under an argon atmosphere to ensure an inert atmosphere in the furnace cavity, then raise the temperature to 1000 ° C, and adjust the argon flow rate to 200sccm, keep warm for 5h; then cool down to 900°C at a rate of 10°C / min, on the basis of an argon flow rate of 200sccm, feed ethylene gas with a flow rate of 100sccm, keep for 1h for chemical vapor deposition carbon coating, and finally cool naturally , to obtain a silicon oxide carbon composite anode material (SiO / SNWs@C) connected by silicon nanowires.

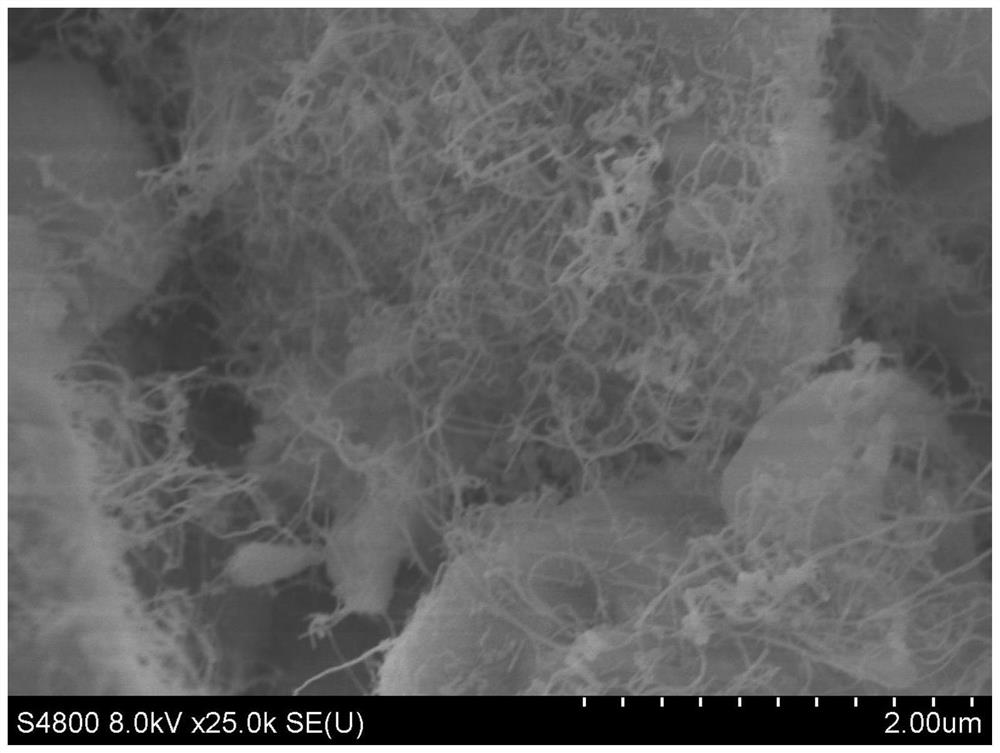

[0066] The scanning electron microscope image of the silicon oxide carbon composite negative electrode material connected by silicon nanowires provided in Example 1 of the present invention is as follows figure 1 shown.

Embodiment 2

[0068] Put 1.5 g of commercial silicon monoxide (SiO) with a particle size of 5 μm in an atmosphere furnace, repeatedly pump out gas under an argon atmosphere to ensure an inert atmosphere in the furnace cavity, then raise the temperature to 1000 ° C, and adjust the argon flow rate to 600sccm, keep warm for 5h; then cool down to 900°C at a rate of 10°C / min, adjust the argon flow rate to 200sccm, feed ethylene gas with a flow rate of 100sccm, keep it for 1h for chemical vapor deposition carbon coating, and finally cool naturally to obtain silicon Nanowire-connected silicon oxide carbon composite anode materials (SiO / SNWs@C).

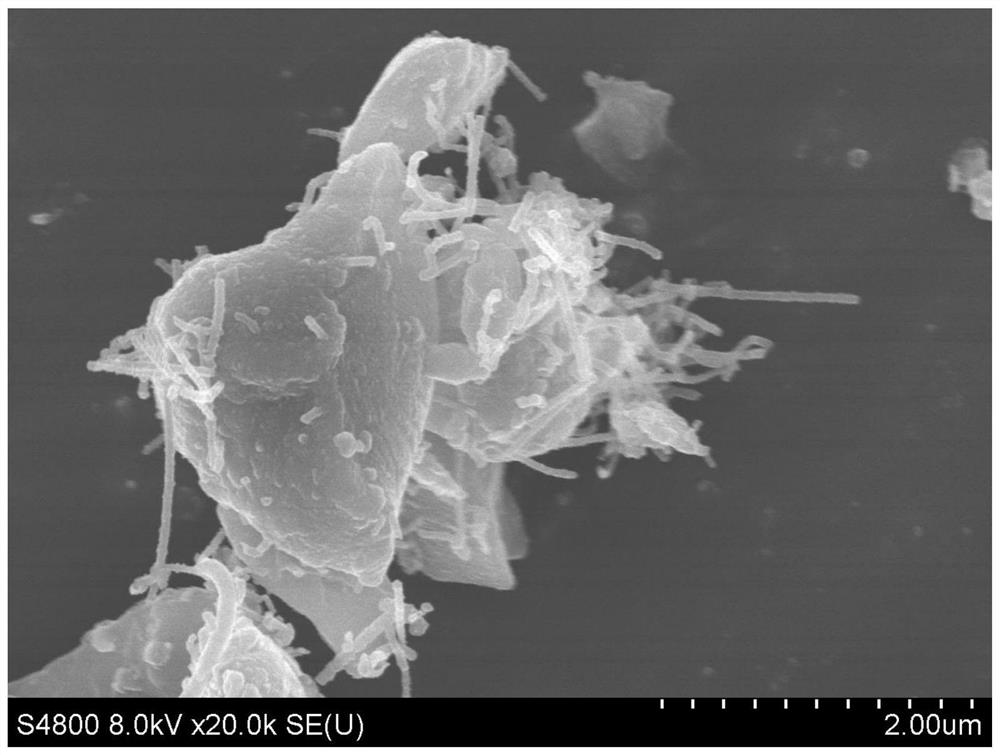

[0069] The scanning electron microscope image of the silicon oxide carbon composite negative electrode material connected by silicon nanowires provided in Example 2 of the present invention is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com