Silicon oxide-carbon composite negative electrode material and preparation method thereof and lithium-ion battery

A technology of negative electrode material and composite material, which is applied to silicon oxide carbon composite negative electrode material, its preparation method and the field of lithium ion battery, can solve the problems of high preparation cost, high cost, difficult to realize practical production and application, etc., and achieves simple and easy preparation method. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a silicon oxide carbon composite negative electrode material, comprising the following steps:

[0034] a) heating silicon oxide to a first temperature under an inert atmosphere, adjusting the flow rate of the inert gas, and keeping it warm to obtain a silicon oxide composite material connected by silicon nanowires; the first temperature is 800°C to 1300°C; the inert gas The flow rate is 0sccm~800sccm;

[0035] b) adjusting the silicon oxide composite material connected by silicon nanowires obtained in step a) to a second temperature, and under the condition of feeding an inert gas, feeding a carbon source gas to carry out chemical vapor deposition, and obtaining a silicon oxide carbon composite negative electrode after cooling Material; the second temperature is 600°C to 1000°C.

[0036] In the present invention, the temperature of silicon oxide is raised to the first temperature in an inert atmosphere, the flow rate of the...

Embodiment 1

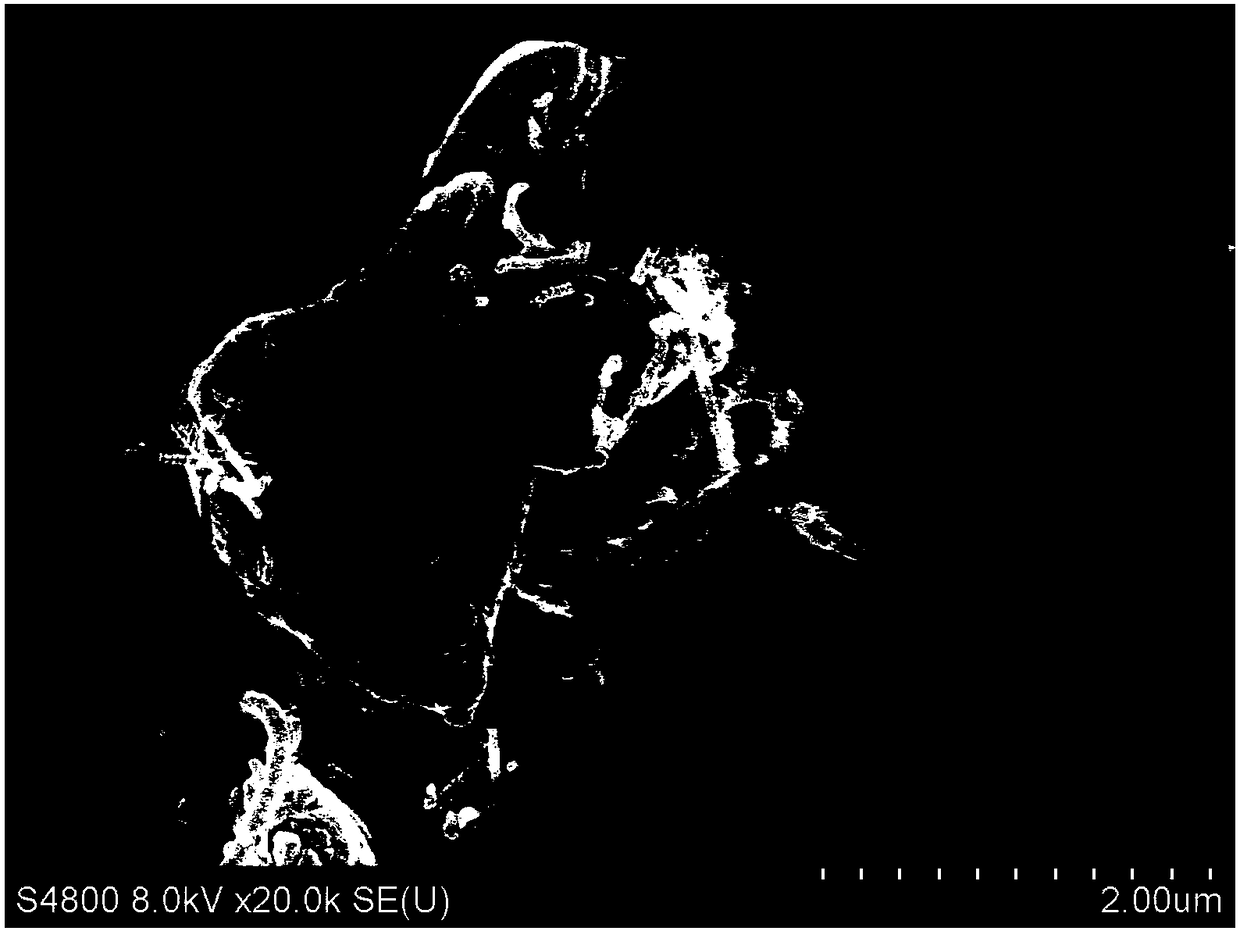

[0065] Put 1.5 g of commercial silicon monoxide (SiO) with a particle size of 5 μm in an atmosphere furnace, repeatedly pump out gas under an argon atmosphere to ensure an inert atmosphere in the furnace cavity, then raise the temperature to 1000 ° C, and adjust the argon flow rate to 200sccm, keep warm for 5h; then cool down to 900°C at a rate of 10°C / min, on the basis of an argon flow rate of 200sccm, feed ethylene gas with a flow rate of 100sccm, keep for 1h for chemical vapor deposition carbon coating, and finally cool naturally , to obtain a silicon oxide carbon composite anode material (SiO / SNWs@C) connected by silicon nanowires.

[0066] The scanning electron microscope image of the silicon oxide carbon composite negative electrode material connected by silicon nanowires provided in Example 1 of the present invention is as follows figure 1 shown.

Embodiment 2

[0068] Put 1.5 g of commercial silicon monoxide (SiO) with a particle size of 5 μm in an atmosphere furnace, repeatedly pump out gas under an argon atmosphere to ensure an inert atmosphere in the furnace cavity, then raise the temperature to 1000 ° C, and adjust the argon flow rate to 600sccm, keep warm for 5h; then cool down to 900°C at a rate of 10°C / min, adjust the argon flow rate to 200sccm, feed ethylene gas with a flow rate of 100sccm, keep it for 1h for chemical vapor deposition carbon coating, and finally cool naturally to obtain silicon Nanowire-connected silicon oxide carbon composite anode materials (SiO / SNWs@C).

[0069] The scanning electron microscope image of the silicon oxide carbon composite negative electrode material connected by silicon nanowires provided in Example 2 of the present invention is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com