Gregorian antenna based on super surface

A Gregorian and metasurface technology, applied to antennas, antenna grounding switch structural connections, electrical components, etc., can solve problems such as large phase compensation errors, complexity, and increased phase compensation errors, and achieve accurate wavefront calibration and optimization Radiation characteristics, effects of precise phase compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

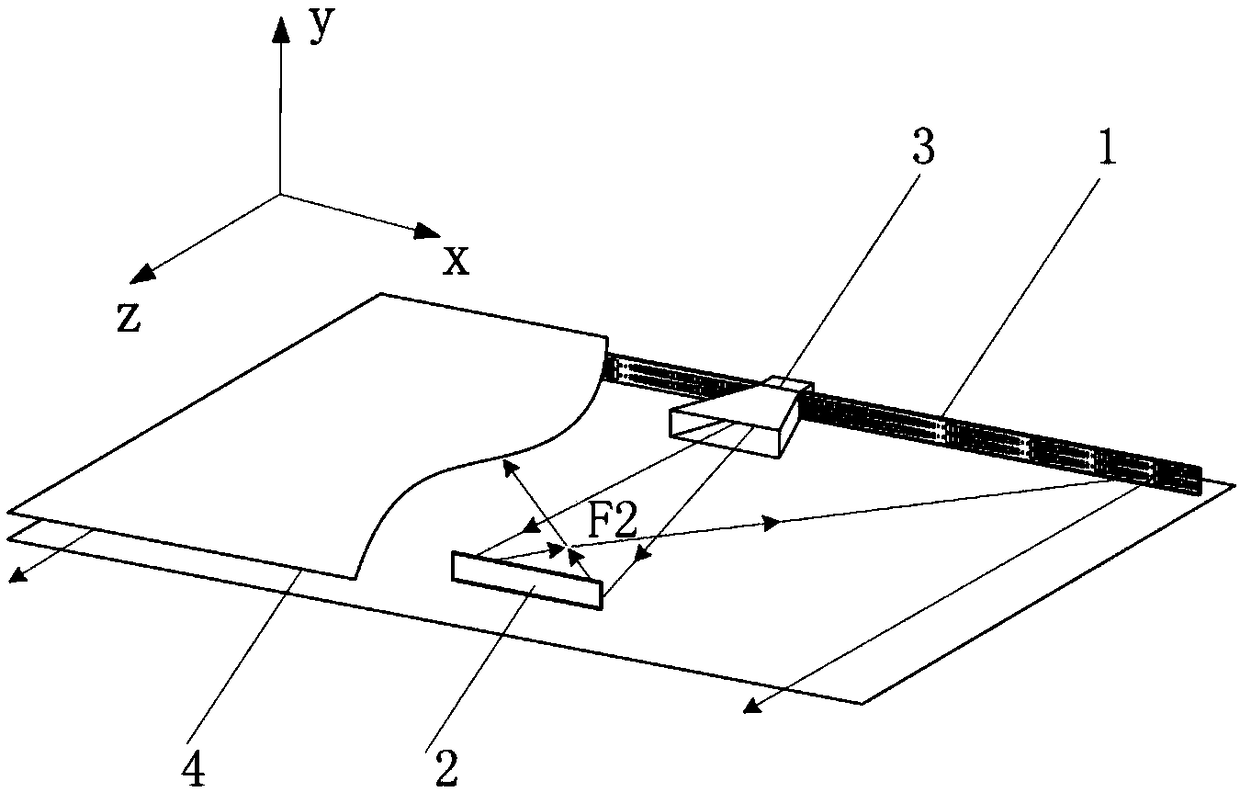

[0030] refer to figure 1 , the present invention includes a primary reflector 1, a secondary reflector 2, a feed source 3 and a slab waveguide 4, and the primary reflector 1, the secondary reflector 2 and the feed source 3 are clamped between two metal plates of the slab waveguide 4 . The setting of main reflector 1 and sub-reflector 2 adopts the feed-forward method, the main reflector 1 and sub-reflector 2 are arranged in parallel, the feed source 3 is located at the disconnected position of the midpoint of the main reflector 1, and the feed source 3 adopts an H-surface rectangular horn Structure, the slab waveguide 4 is composed of two rectangular metal plates of the same size, which is used to confine the uncompleted phase-compensated electromagnetic wave between the two metal plates of the slab waveguide, and the cylindrical wave emitted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com