Method for promoting startup of anaerobic reactor

An anaerobic reactor and composite anaerobic technology are used in the field of using conductive particles to promote the start-up of anaerobic reactors. Transfer efficiency, sludge loss prevention, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

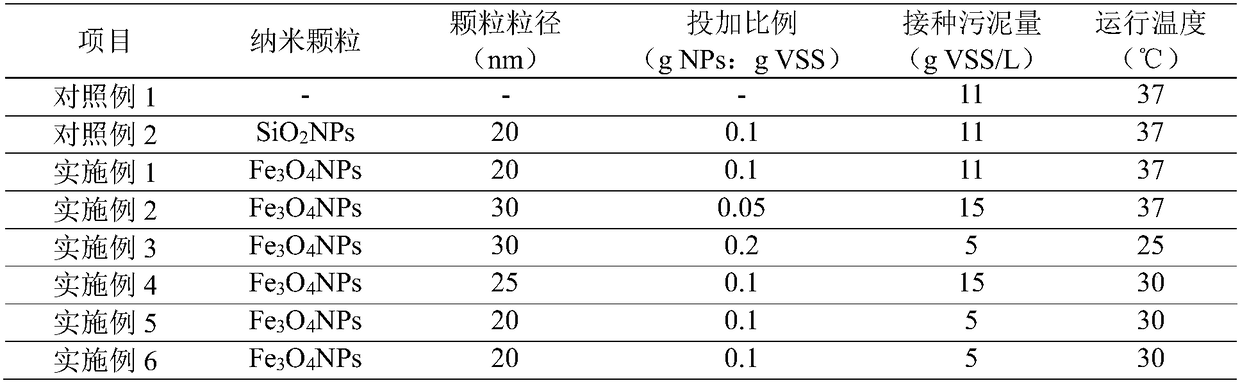

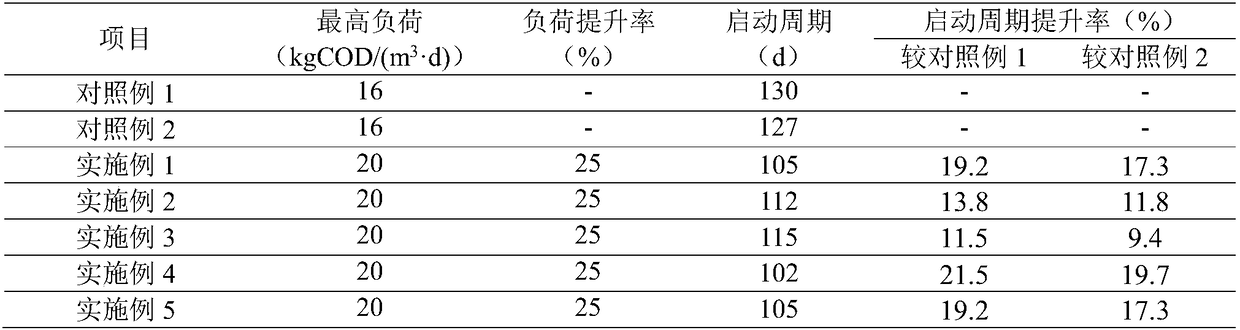

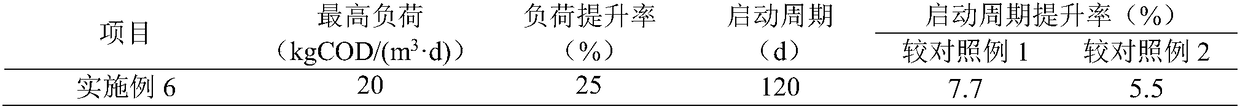

Embodiment 1

[0054] The present embodiment 1 is to inoculate the anaerobic activated sludge reactor experimental group containing conductive nano-ferric oxide particles, and the specific operations are as follows:

[0055] Step (1), get the compound anaerobic activated sludge test that contains conductive nano ferric oxide: will be taken from the sludge sieve of the sludge thickening tank of the municipal sewage treatment plant, remove larger particles, get the sieved sludge 3.3 L adds 2.7L nanometer iron ferric oxide dispersion liquid, described anaerobic sludge concentration 20gVSS / L, in nanometer iron ferric oxide dispersion liquid preparation step, iron ferric oxide nanoparticle is added in deionized water, ultrasonic dispersion 30min , power 200W, the temperature of the deionized water does not exceed 40 ° C, the preparation of nano ferric oxide dispersion. Described nanometer ferric oxide dispersion liquid concentration 2.4g / L, in described nanometer ferric oxide dispersion liquid, f...

Embodiment 2

[0061] The present embodiment 2 is to inoculate the anaerobic activated sludge reactor experimental group containing conductive nano-ferric oxide particles, and the specific operations are as follows:

[0062] Step (1), get the compound anaerobic activated sludge test that contains conductive nano-ferric oxide: will be taken from the sludge sieve of the sludge concentration tank of the municipal sewage treatment plant, remove larger particles, get the sieved sludge 4.5 L adds 1.5L nanometer ferric oxide dispersion liquid, described anaerobic sludge concentration 20gVSS / L, described nanometer ferric oxide dispersion liquid concentration 3g / L, in described nanometer ferric oxide dispersion liquid Iron (Fe 3 o 4 NPs) particle size is 30nm; Fe 3 o 4 NPs: dry weight of anaerobic activated sludge (VSS) = 0.05:1 (mass ratio), slowly stirred at room temperature 25°C for 24h, and agitated at a speed of 100rpm for anaerobic culture to prepare inoculum sludge.

[0063] Step (2), inoc...

Embodiment 3

[0068] The present embodiment 3 is to inoculate the anaerobic activated sludge reactor experimental group containing conductive nano-ferric oxide particles, and the specific operations are as follows:

[0069] Step (1), get the compound anaerobic activated sludge test that contains conductive nano-ferric oxide: will be taken from the sludge sieve of the sludge concentration tank of the municipal sewage treatment plant, remove larger particles, get the sieved sludge 4.5 L adds 1.5L nanometer ferric oxide dispersion liquid, described anaerobic sludge concentration 20gVSS / L, described nanometer ferric oxide dispersion liquid concentration 1.3g / L, four in the nanometer ferric oxide dispersion liquid Ferric oxide (Fe 3 o 4 NPs) particle size is 30nm; Fe 3 o 4 NPs: dry weight of anaerobic activated sludge (VSS) = 0.2:1 (mass ratio), slowly stirred at room temperature 25°C for 24 hours, and performed anaerobic culture at a stirring speed of 100rpm to prepare inoculum sludge.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com