A kind of pseudo high-entropy alloy coating formula and coating preparation method thereof

A high-entropy alloy and coating technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of reducing laser energy density, unsuitable shape, low growth speed, etc., and it is easy to achieve element ratio Conditioning, increasing possibilities, tissue homogeneity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

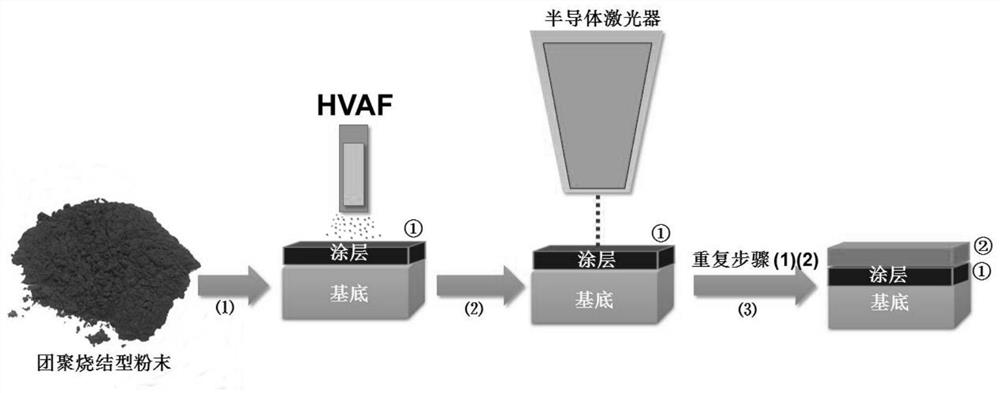

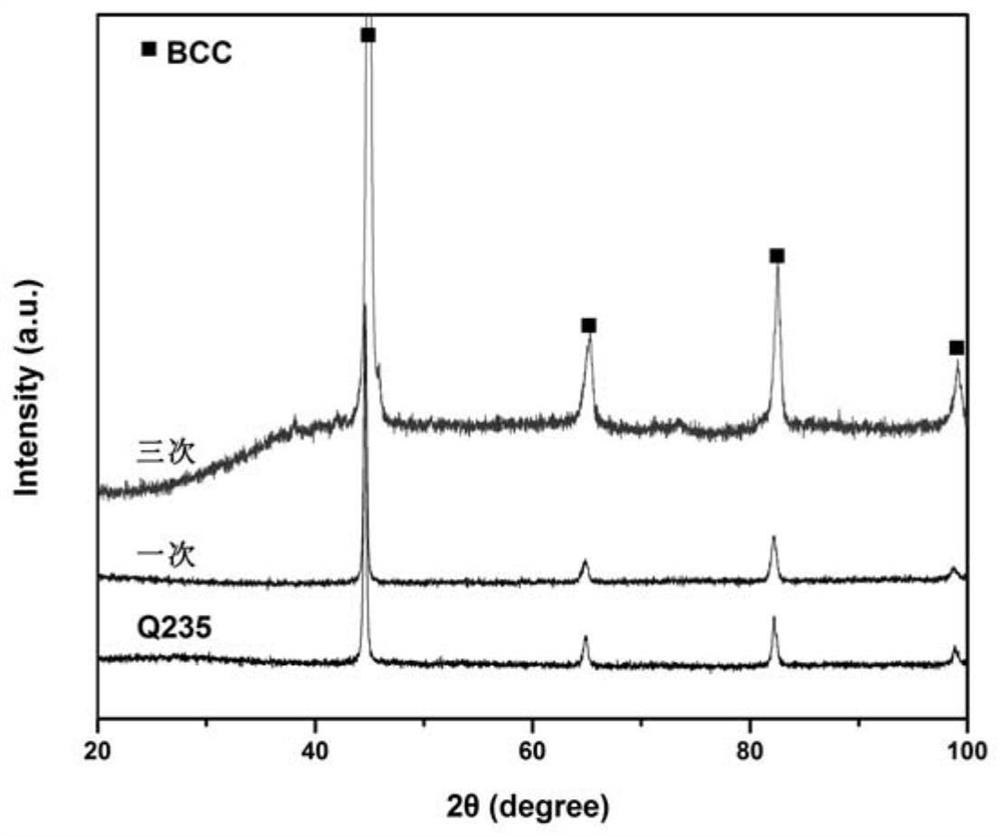

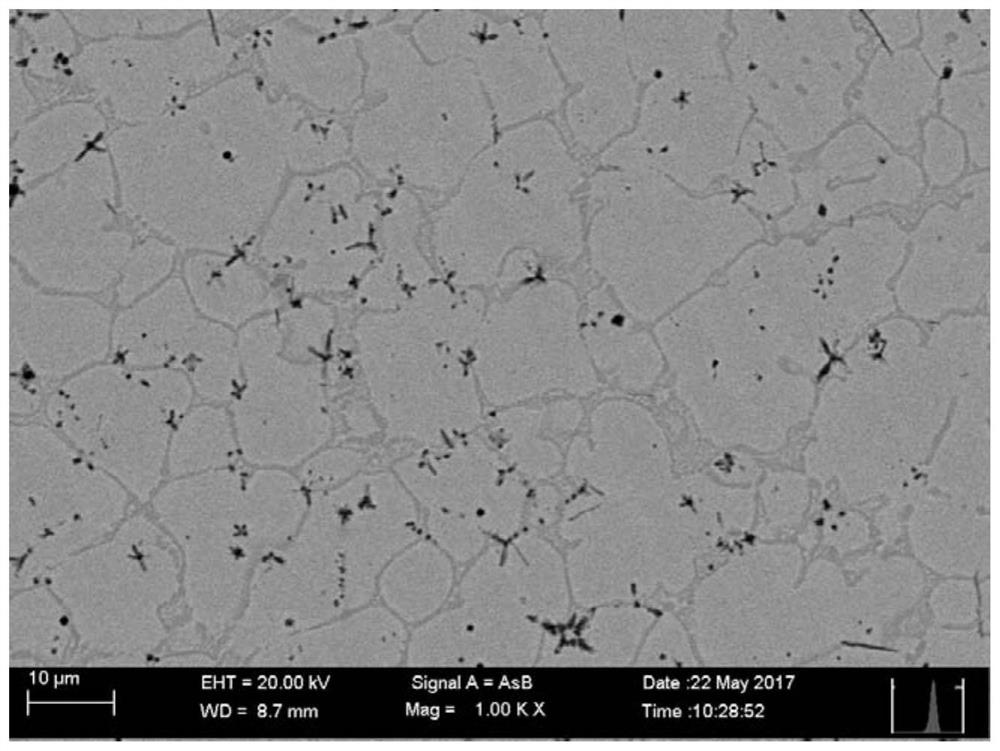

[0031] The invention relates to a high-hardness corrosion-resistant Fe 主 The preparation method of Co Ni Cr Al Ti Si pseudo high-entropy alloy coating comprises the following steps:

[0032] Step 1. Mix the elemental powders of seven elements including Fe, Co, Ni, Cr, Al, Ti and Si evenly according to the equal atomic ratio;

[0033] Step 2. Add a binder to the mixed powder obtained in step 1, and mix the fine raw material powder by ball milling to form a slurry. The slurry is made into a certain size precursor powder through a spray drying device, and then sintered and sieved Produce powders with a size between 5 and 35 μm;

[0034] Step 3. Add the agglomerated and sintered powder obtained by screening in step 2 into the powder feeder, and use atmospheric supersonic flame spraying (HVAF) technology, air pressure 100PSI, gas pressure 90PSI, nitrogen flow rate 30slpm, hydrogen flow rate 30slpm, spraying distance 250mm , forming a preset coating with a thickness of 400 μm on t...

Embodiment 2

[0043] The invention relates to a high-hardness corrosion-resistant Fe 主 The preparation method of Co Ni Cr Al Ti Si pseudo high-entropy alloy coating comprises the following steps:

[0044] Step 1. Mix the elemental powders of seven elements uniformly according to the following atomic percentage content, the content of Fe is 5 at%, and the remaining 95 at% of Co Ni Cr Al Ti Si is evenly divided;

[0045] Step 2. Add a binder to the mixed powder obtained in step 1, and mix the fine raw material powder by ball milling to form a slurry. The slurry is made into a certain size precursor powder through a spray drying device, and then sintered and sieved Produce powders with a size between 5 and 35 μm;

[0046] Step 3. Add the agglomerated and sintered powder obtained by screening in step 2 into the powder feeder, and use atmospheric supersonic flame spraying (HVAF) technology, air pressure 85PSI, gas pressure 80PSI, nitrogen flow rate 15slpm, hydrogen flow rate 15slpm, spraying di...

Embodiment 3

[0050] The invention relates to a high-hardness corrosion-resistant Fe 主 The preparation method of Co Ni Cr Al Ti Si pseudo high-entropy alloy coating comprises the following steps:

[0051] Step 1. Mix the elemental powders of the seven elements uniformly according to the following atomic percentage content, the content of Fe is 10 at%, and the remaining 90 at% of Co Ni Cr Al Ti Si is evenly divided;

[0052] Step 2. Add a binder to the mixed powder obtained in step 1, and mix the fine raw material powder into a slurry, and use a spray drying device to make the slurry into a certain size precursor powder, and then go through degreasing, sintering, Sieve out powders with a size between 5 and 35 μm;

[0053] Step 3. Add the agglomerated and sintered powder obtained by screening in step 2 into the powder feeder, and use atmospheric supersonic flame spraying (HVAF) technology, air pressure 90PSI, gas pressure 90PSI, nitrogen flow rate 20slpm, hydrogen flow rate 20slpm, spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com