Catalyst for catalytically oxidizing low-concentration methane as well as preparation method and application of catalyst

A catalytic oxidation and catalyst technology, applied in the field of energy saving and environmental protection, can solve the problems of reducing exhaust gas, etc., and achieve the effect of high efficiency, high dispersion and good relative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the catalyst for catalytic oxidation of low-concentration methane, comprising the following steps:

[0040] A) Preparation of octahedral CeO by hydrothermal synthesis 2 particles;

[0041] B) the palladium source compound, citrate and the octahedral CeO 2 The particles are dispersed in water to obtain a suspension;

[0042] C) adding the reducing agent dropwise to the suspension, mixing and stirring to react to obtain the suspension;

[0043] D) drying and calcining the suspension to obtain a catalyst.

[0044] Firstly, octahedral CeO was prepared by hydrothermal synthesis 2 Particles, the specific preparation method is as described above, and will not be repeated here.

[0045] Get octahedral CeO 2 After the particles, the palladium source compound, citrate and the octahedral CeO 2 The particles are dispersed in water to obtain a suspension.

[0046] Specifically, the palladium source compound is dissolv...

Embodiment 1

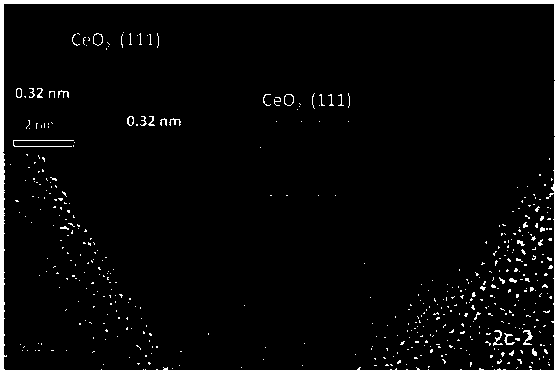

[0077] Octahedral CeO 2 method of preparation.

[0078] 2.17g cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) Dissolve in 40ml of deionized water, then add 0.019g of trisodium phosphate, and fully stir at room temperature for 1h to form a uniform mixed solution. Then the mixed solution was transferred to a 250ml stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining and sealed, and heated in an oven at 170°C for 12h. After the solution was cooled, the obtained precipitate was centrifuged at 9000 rpm, washed repeatedly with deionized water and ethanol, and finally dried in an oven at 60°C for 12 hours to obtain a white solid (octahedral CeO 2 ).

[0079] 0.1mmolNa 2 PdCl 4 Dissolve in 100ml of deionized water, then add 0.8mmol of sodium citrate and fully dissolve. Then add 0.5247g octahedral CeO to the mixed solution 2 powder and sonicated for 1 h. 100ml of 0.1M NaBH 4 The solution was added dropwise to the suspension and stirred well at ro...

Embodiment 2

[0083] 2.17g cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) Dissolve in 40ml of deionized water, then add 0.019g of trisodium phosphate, and fully stir at room temperature for 1h to form a uniform mixed solution. Then the mixed solution was transferred to a 250ml stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining and sealed, and heated in an oven at 180°C for 24h. After the solution was cooled, the obtained precipitate was centrifuged at 9000 rpm, washed repeatedly with deionized water and ethanol, and finally dried in an oven at 60°C for 12 hours to obtain a white solid (cubic CeO 2 ).

[0084] 0.1mmolNa 2 PdCl 4 Dissolve in 100ml of deionized water, then add 0.8mmol of sodium citrate and fully dissolve. Then add 0.5247g cubic CeO to the mixed solution 2 powder and sonicated for 1 h. 100ml of 0.1M NaBH 4 The solution was added dropwise to the suspension and stirred well at room temperature. Then the mixed solution was fully stirred fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com