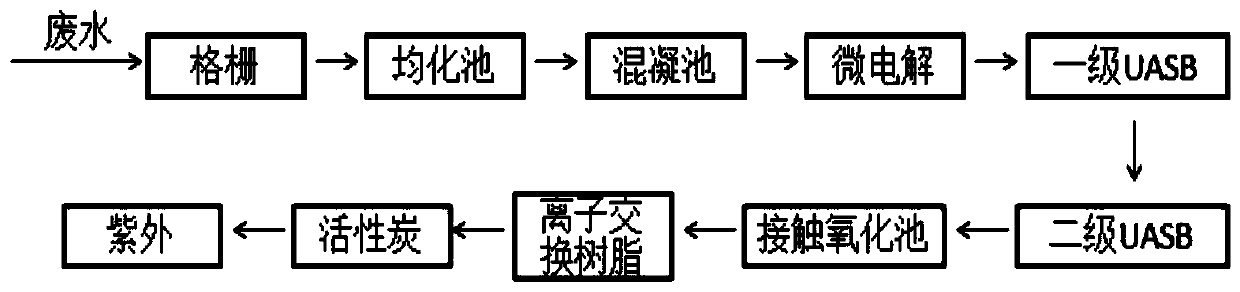

A papermaking wastewater treatment process

A technology for papermaking wastewater and treatment process, applied in the field of papermaking industry, can solve the problems of low recycling rate, low efficiency and high cost, and achieve the effects of prolonging service life, improving degradation efficiency and delaying attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The COD in the papermaking wastewater to be treated is 4803mg / L, and the SS is 570mg / L.

[0024] Filter the papermaking wastewater to be treated through the grid, introduce it into the homogenization tank, add acid to adjust the pH value to 6.8, and the residence time is 0.5 hours; enter the treated wastewater into the coagulation tank, add magnetic seeds and coagulant polyacrylamide , wherein the amount of polyacrylamide added is 50ppm, the mass ratio of the magnetic seed to polyacrylamide is 1:2, fully stirred and mixed, and then magnetically separates the mixed liquid by using a disk to separate the mud and water; the treated wastewater Enter the micro-electrolysis treatment: add a small amount of acid to the iron-carbon micro-electrolysis cell to adjust the pH value to 3.5, and perform iron-carbon micro-electrolysis. At the same time, the bottom of the iron-carbon micro-electrolysis cell is aerated. Hours; the treated wastewater is sent to the first-level UASB and t...

Embodiment 2

[0026] The COD in the papermaking wastewater to be treated is 4503mg / L, and the SS is 450mg / L.

[0027] Filter the papermaking wastewater to be treated through the grid, introduce it into the homogenization tank, add acid to adjust the pH value to 7, and the residence time is 0.5 hours; enter the treated wastewater into the coagulation tank, add magnetic seeds and coagulant polyacrylamide , wherein the amount of polyacrylamide added is 60ppm, the mass ratio of the magnetic seed to polyacrylamide is 1:2.5, fully stirred and mixed, and then magnetically separates the mixed liquid by using a disk to separate the mud and water; the treated wastewater Enter the micro-electrolysis treatment: add a small amount of acid to the iron-carbon micro-electrolysis cell to adjust the pH value to 3, and carry out iron-carbon micro-electrolysis. At the same time, the bottom of the iron-carbon micro-electrolysis cell is aerated. Hours; the treated wastewater is sent to the first-level UASB and t...

Embodiment 3

[0029] The COD in the papermaking wastewater to be treated is 3675mg / L, and the SS is 1080mg / L.

[0030]Filter the papermaking wastewater to be treated through the grid, introduce it into the homogenization tank, add acid to adjust the pH value to 7.2, and the residence time is 1 hour; enter the treated wastewater into the coagulation tank, add magnetic seeds and coagulant polyacrylamide , wherein the amount of polyacrylamide added is 80ppm, the mass ratio of the magnetic seed to polyacrylamide is 1:3, fully stirred and mixed, and then magnetically separates the mixed liquid by using a disk to separate the mud and water; the treated wastewater Enter the micro-electrolysis treatment: add a small amount of acid to the iron-carbon micro-electrolysis cell to adjust the pH value to 4, and carry out iron-carbon micro-electrolysis. At the same time, the bottom of the iron-carbon micro-electrolysis cell is aerated. Hours; the treated wastewater is sent to the first-level UASB and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com