Organism implant, components thereof and preparation method thereof

A technology of implants and organisms, applied in prosthesis, medical science, surgery, etc., can solve problems such as delayed healing, failure of magnesium alloy implants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

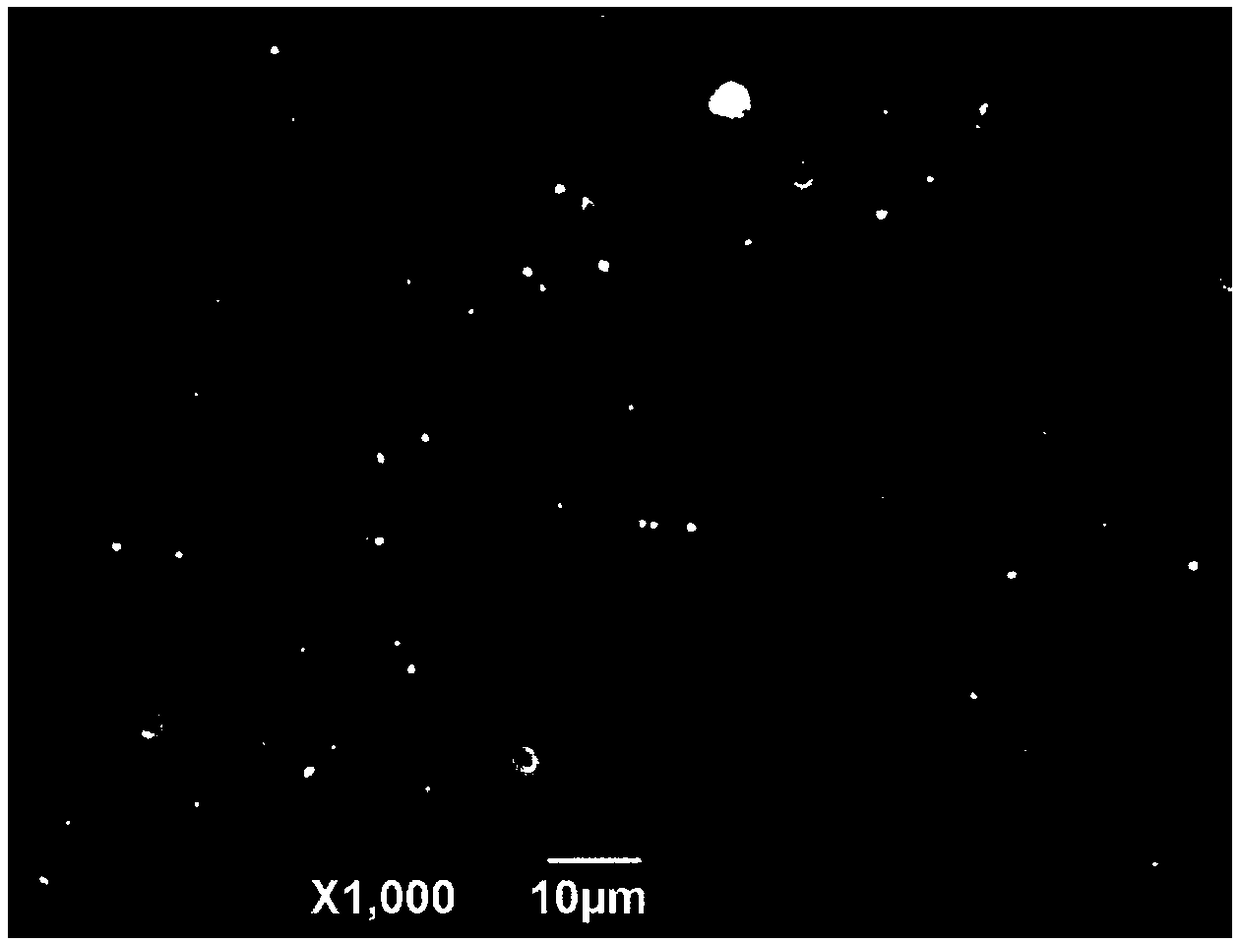

Embodiment 1

[0051] First carry out the raw material configuration according to the following alloy raw materials: magnesium ingots with a purity greater than 99.9% are used as magnesium raw materials, magnesium-5.66% calcium master alloys (Mg-Ca master alloys) with a purity greater than 99.9% are used as calcium raw materials, and zinc particles with a purity greater than 99.9% as zinc raw material.

[0052] Dry the cast iron mold at 200°C for 2 hours and then put it into a medium-frequency induction furnace (rated frequency 2500Hz). In addition, pre-bake the graphite crucible in the induction furnace for 20 minutes to remove moisture and put it into the acid-washed and dried Magnesium ingots and Mg-Ca master alloy; while zinc particles are added to the secondary feeding hopper. After closing the furnace cover, start vacuuming. When the vacuum degree reaches 0.02 Pa, start filling argon gas until the pressure gauge shows -0.076 MPa. The magnesium ingot and the master alloy have melted, s...

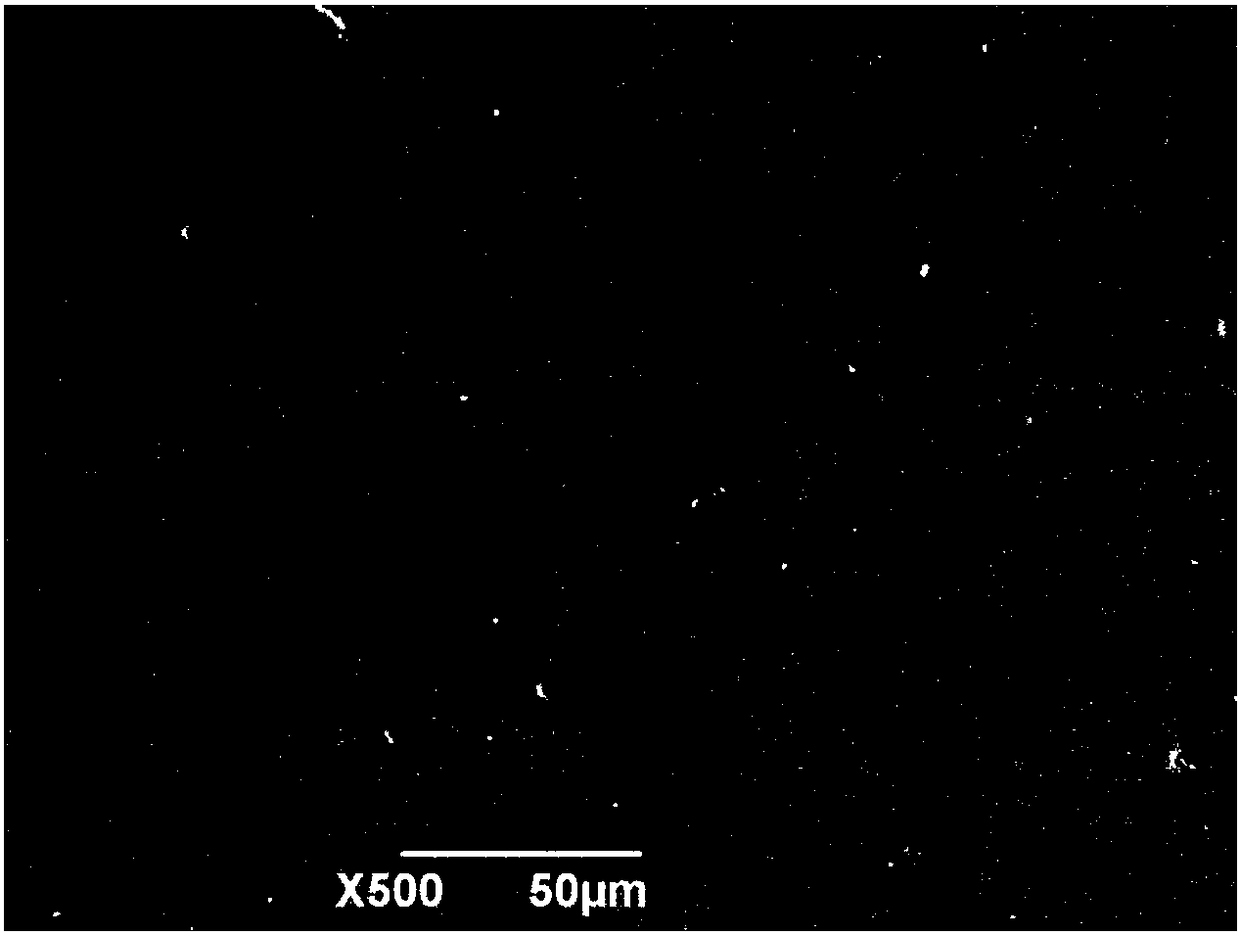

Embodiment 2

[0067] First carry out the raw material configuration according to the following alloy raw materials: magnesium ingots with a purity greater than 99.9% are used as magnesium raw materials, magnesium-5.66% calcium master alloys (Mg-Ca master alloys) with a purity greater than 99.9% are used as calcium raw materials, and zinc particles with a purity greater than 99.9% as zinc raw material.

[0068] Dry the cast iron mold at 200°C for 2 hours and put it into a medium-frequency induction furnace. In addition, pre-bake the graphite crucible in the induction furnace for 20 minutes to remove moisture and put it into pickled and dried magnesium ingots, Mg -Ca master alloy; while zinc pellets are added to the secondary hopper. After closing the furnace cover, start to vacuumize. When the vacuum reaches 0.02 Pa, start to fill in argon until the pressure gauge shows -0.074 MPa. At this time, start to send electricity, and the electric power is 20KW to 24KW; The master alloy has been mel...

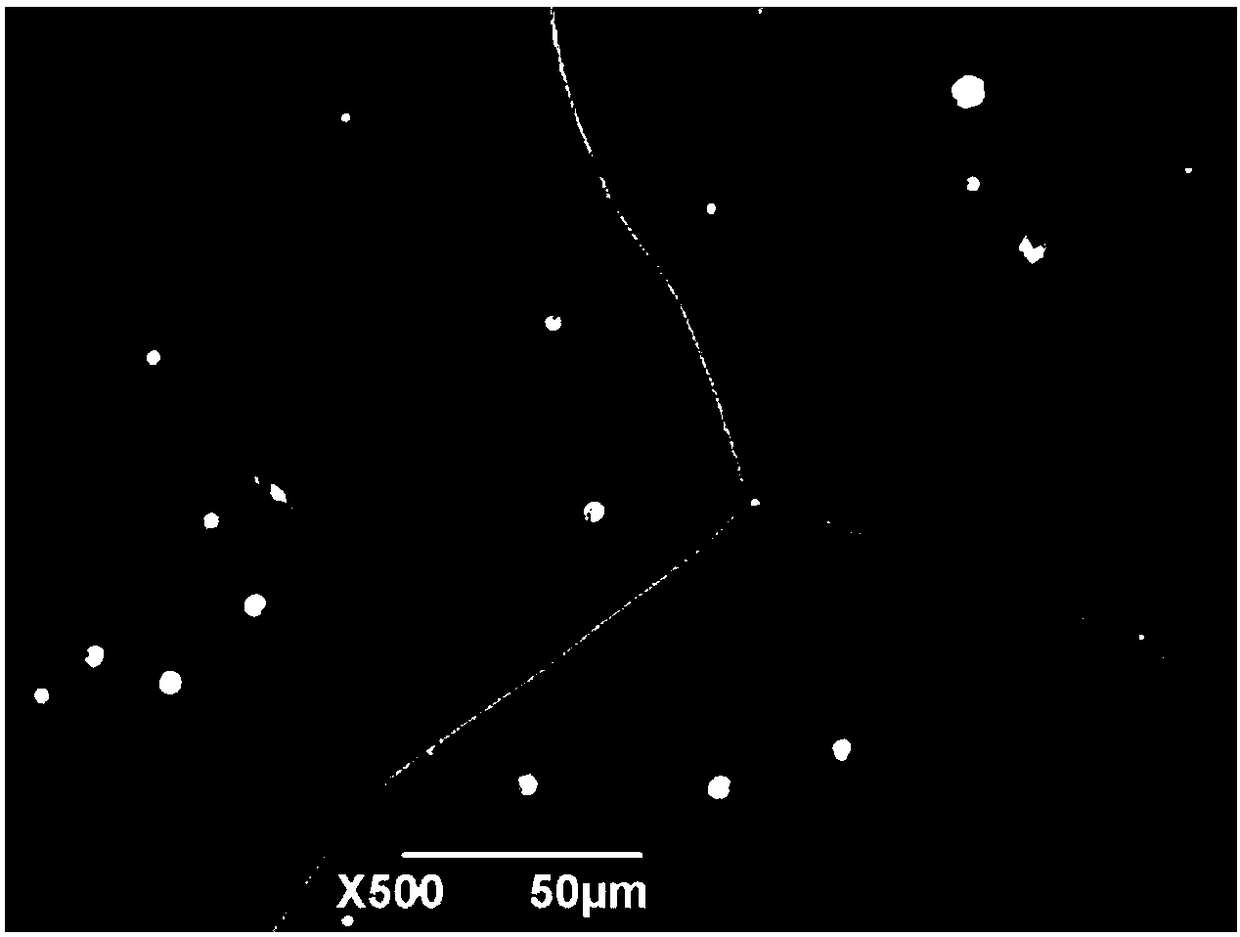

Embodiment 3

[0082] First carry out the raw material configuration according to the following alloy raw materials: magnesium ingots with a purity greater than 99.9% are used as magnesium raw materials, magnesium-5.58% calcium master alloys (Mg-Ca master alloys) with a purity greater than 99.9% are used as calcium raw materials, and zinc particles with a purity greater than 99.9% as zinc raw material.

[0083] Dry the cast iron mold at 200°C for 2 hours and put it into a medium-frequency induction furnace. In addition, pre-bake the graphite crucible in the induction furnace for 20 minutes to remove moisture and put it into pickled and dried magnesium ingots, Mg -Ca master alloy; while zinc pellets are added to the secondary hopper. Start vacuuming after closing the furnace cover. When the vacuum degree reaches 0.02 Pa, start to fill in argon until the pressure gauge shows -0.068 MPa. The master alloy has been melted, then suspend the power transmission, and then continue the power transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com