Method for real-time monitoring of crack on composite-repaired structure based on fiber Bragg grating (FBG) sensor

A composite material and real-time monitoring technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, and analyzing materials through optical means to achieve good compatibility, high sensitivity, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

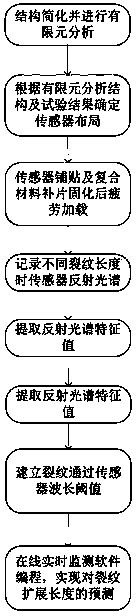

[0025] The invention is a crack diagnosis method based on the spectral characteristics of the fiber Bragg grating sensor, the process is as follows figure 1 As shown, the specific steps are as follows:

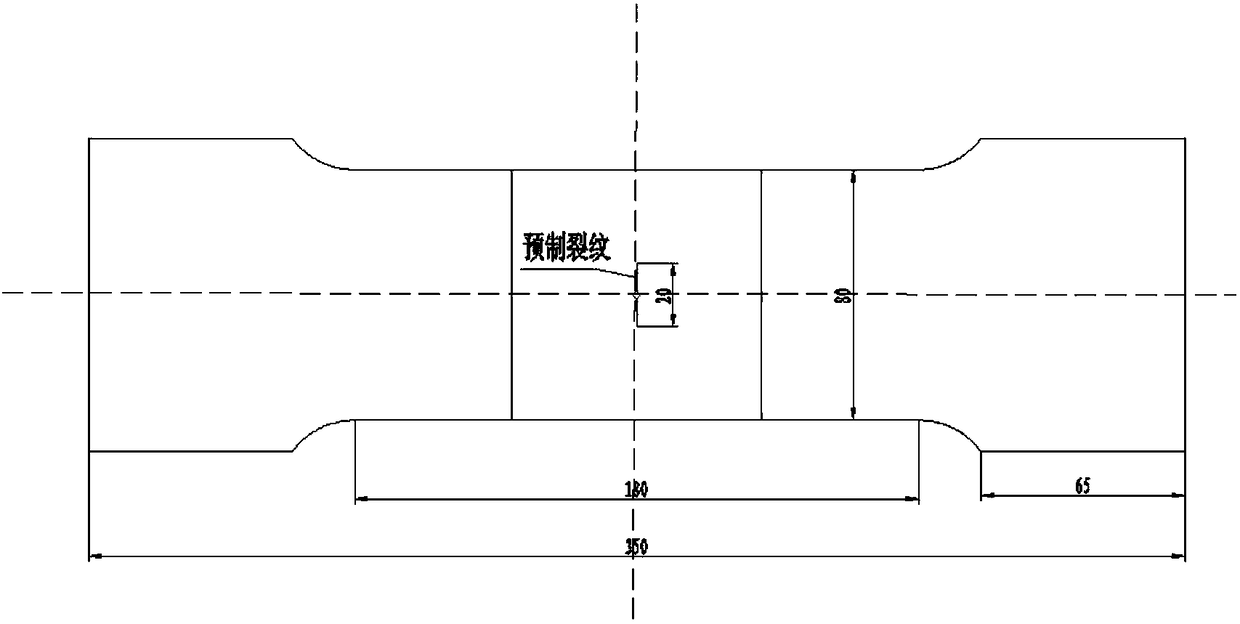

[0026] Step 1: Select the test piece and design the sample piece. Its specification is 350mm*80mm*3mm, and the material is 2A12 aluminum alloy sheet. mm center hole, and prefabricated cracks with a predetermined length of 20mm on both sides of the hole, using wire cutting, such as figure 2 shown;

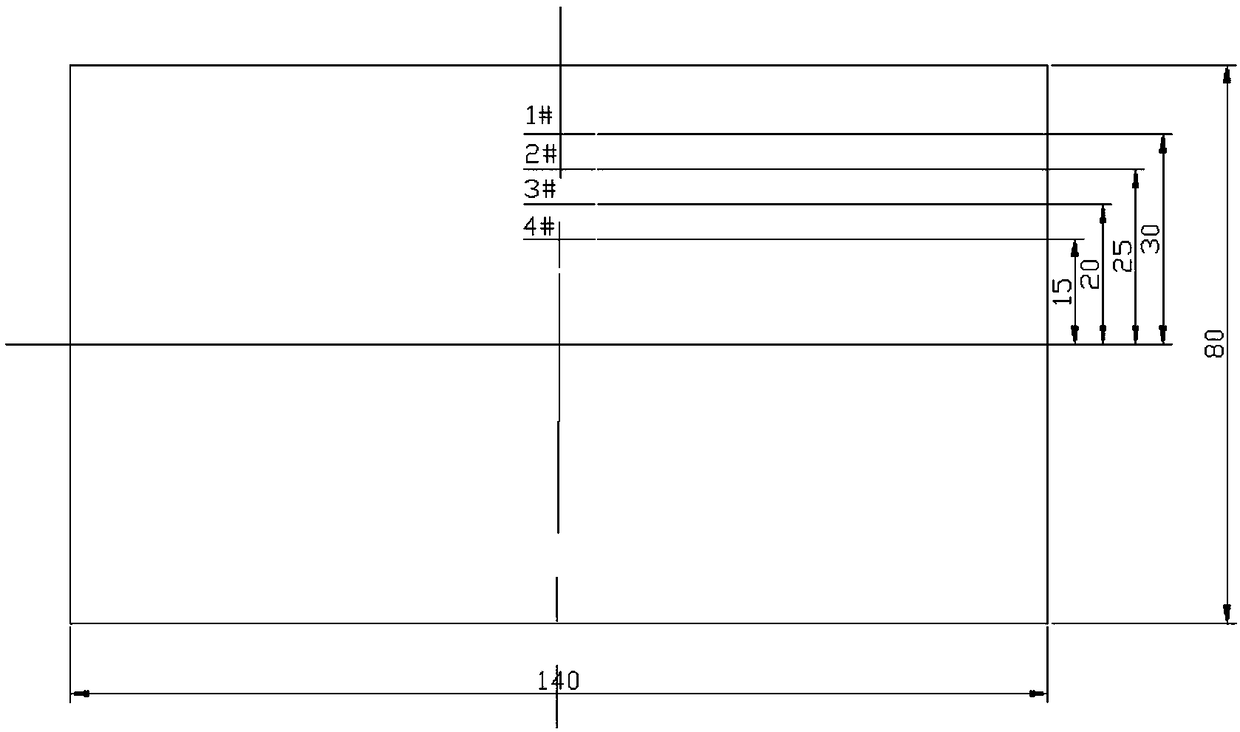

[0027] Step 2: Carry out structural mechanics analysis on the sample, analyze the stress at both ends of the sample, and perform finite element simulation analysis on the sample to determine the stress distribution of the crack tip area when the crack extends to a specific length; Before the finite element analysis, it is necessary to determine the external loading conditions, such as the type of load, and related parameters such as the material of the sample, elastic modulus, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com