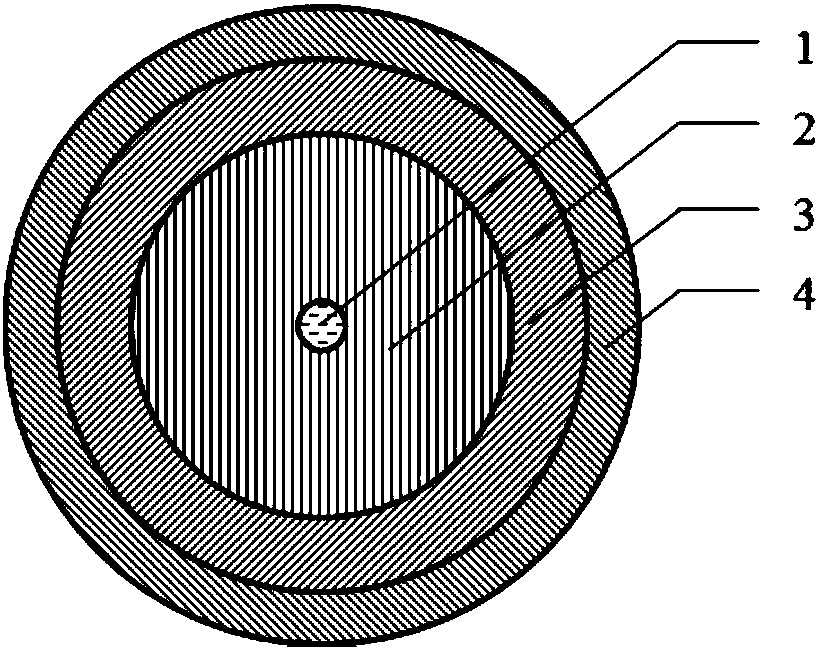

Radiation-resistant and high-low-temperature single-mode optical fiber

A high and low temperature resistant, single-mode fiber technology, applied in glass fiber, cladding fiber, optical waveguide light guide, etc., to achieve the effect of low induced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The composition of the quartz core of embodiment 1 is as follows:

[0035] Component element name

mole percent mol%

SiO 2

100

[0036] The composition of the fluorine-doped quartz glass cladding of embodiment 1 is as follows:

[0037] Component element name

mole percent mol%

SiO 2

42

CCl 2 f 2

58

[0038] The preparation method is as follows:

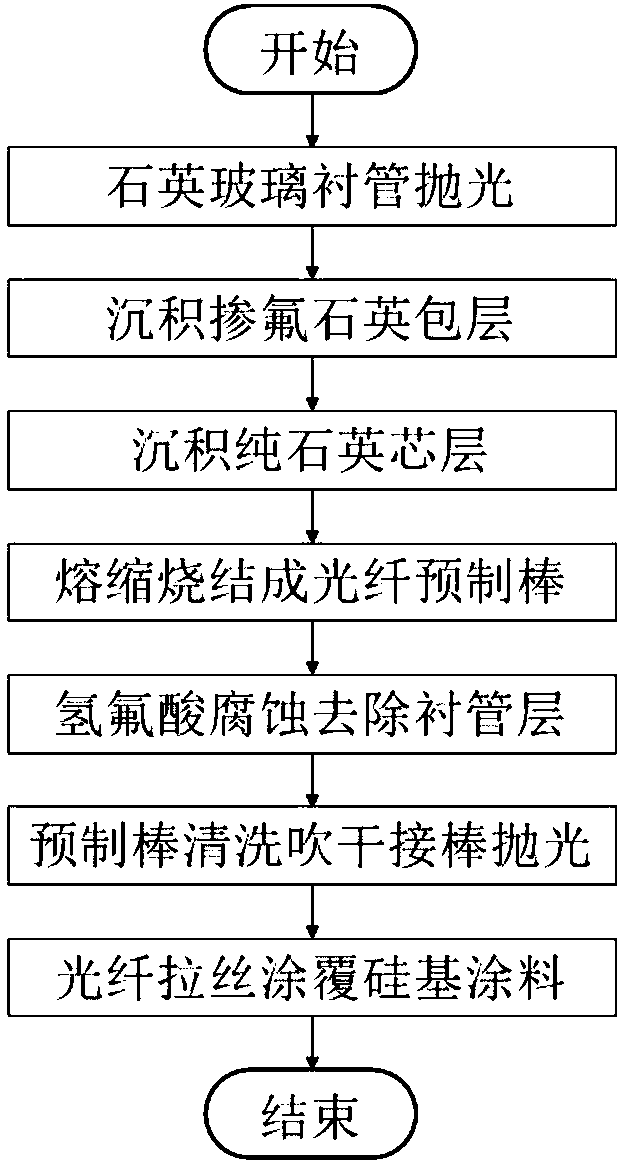

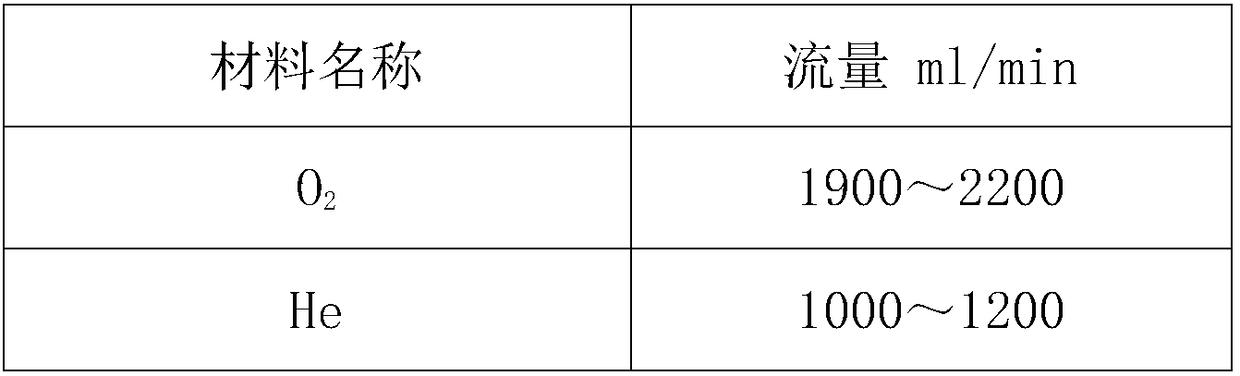

[0039] Step 11. Thin-walled quartz glass liner flame polishing

[0040] A thin-walled quartz glass tube with a single wall thickness of 3 mm is selected as the liner. The outer diameter of the liner is 25 mm, the inner diameter is 19 mm, and the length is 600 mm. Put it on the lathe, by passing SF into the liner 6 Gas and use a hydrogen-oxygen flame to perform high-temperature flame polishing at 2300 ° C to eliminate scratches, impurities, surface unevenness, and shrinkage bubbles on the inner and outer surfaces of the deposition tube. The high-temperat...

Embodiment 2

[0060] The composition of the quartz core of embodiment 2 is as follows:

[0061] Component element name

mole percent mol%

SiO 2

100

[0062] The composition of the fluorine-doped quartz glass cladding of embodiment 2 is as follows:

[0063] Component element name

mole percent mol%

SiO 2

49

CCl 2 f 2

51

[0064] The preparation method is as follows:

[0065] Step 21. Thin-walled quartz glass liner flame polishing

[0066] A thin-walled quartz glass tube with a single wall thickness of 3 mm is selected as the liner. The outer diameter of the liner is 25 mm, the inner diameter is 19 mm, and the length is 600 mm. Put it on the lathe, by passing SF into the liner 6 Gas and use a hydrogen-oxygen flame to perform high-temperature flame polishing at 2300 ° C to eliminate scratches, impurities, surface unevenness, and shrinkage bubbles on the inner and outer surfaces of the deposition tube. The high-temperat...

Embodiment 3

[0086] The composition of the quartz core of embodiment 3 is as follows:

[0087] Component element name

mole percent mol%

SiO 2

100

[0088] The composition of the fluorine-doped quartz glass cladding of embodiment 3 is as follows:

[0089] Component element name

mole percent mol%

SiO 2

59

CCl 2 f 2

41

[0090] The preparation method is as follows:

[0091] Step 31. Thin-walled quartz glass liner flame polishing

[0092] A thin-walled quartz glass tube with a single wall thickness of 3 mm is selected as the liner. The outer diameter of the liner is 25 mm, the inner diameter is 19 mm, and the length is 600 mm. Put it on the lathe, by passing SF into the liner 6 Gas and use a hydrogen-oxygen flame to perform high-temperature flame polishing at 2300 ° C to eliminate scratches, impurities, surface unevenness, and shrinkage bubbles on the inner and outer surfaces of the deposition tube. The high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com