Ozonolysis catalyst and preparing method and application thereof

An ozone decomposition and catalyst technology, which is applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Ozone decomposition ability, rich ozone decomposition active sites, combined with the effect of not easily falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

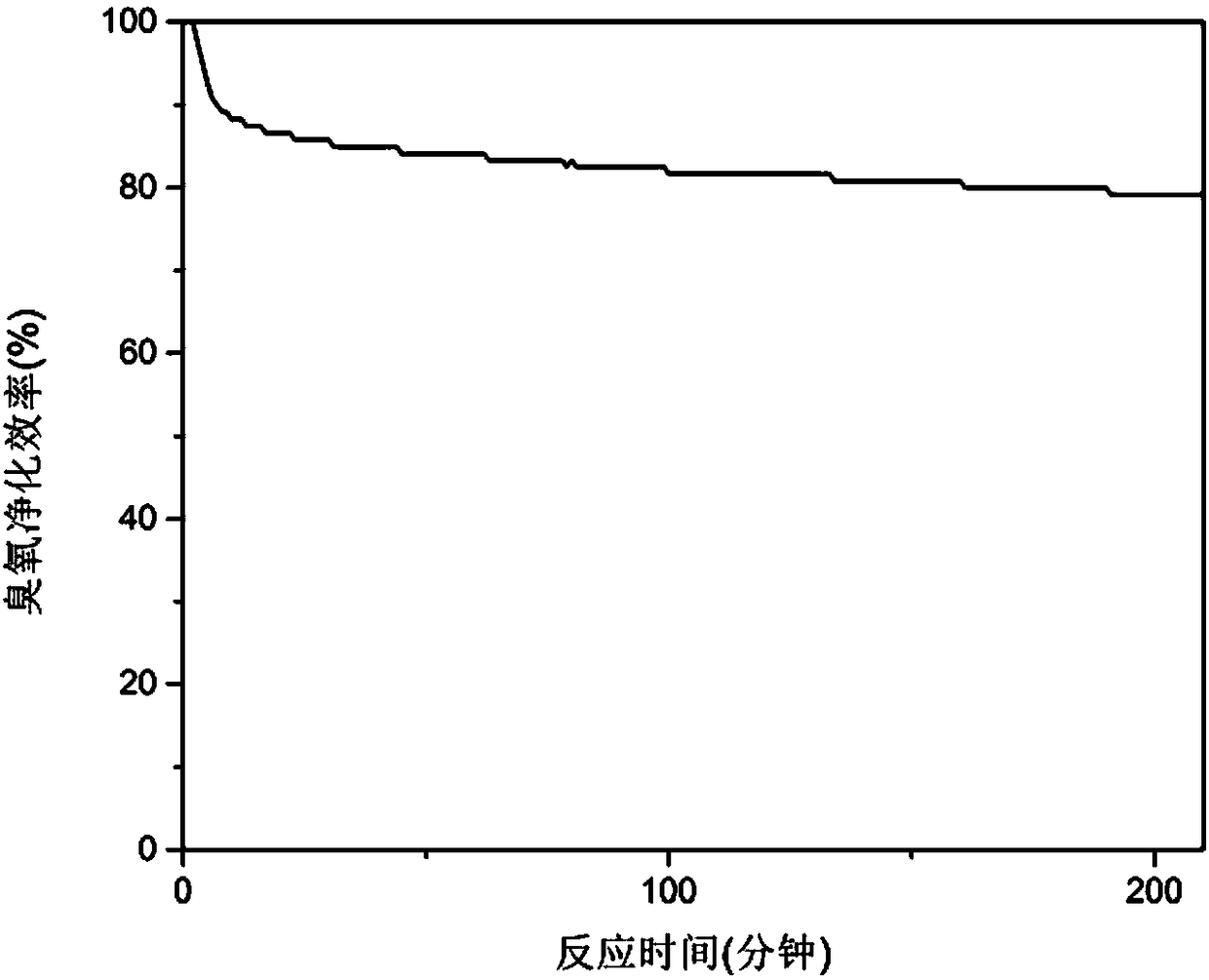

[0049] Weigh 3.16g of potassium permanganate and dissolve it in 50mL of deionized water, mix 150g of alumina pellets with a particle size of 2-3mm with the obtained solution, the potassium permanganate solution will completely wet the alumina pellets and heat at 120°C Drying at low temperature; Dissolve 25mL ethanol and 5mL glacial acetic acid in 30mL deionized water, then mix with the dried carrier, make the liquid fully infiltrate the carrier and stir, then put it in an oven at 50°C for 1 hour constant temperature reaction, remove excess The manganese precursor-coated regular carrier was obtained after the moisture was obtained; the obtained carrier was placed in a muffle furnace, and the temperature was raised to 500°C for 3 hours at a rate of 5°C / min for calcination, and the catalyst product was obtained after natural cooling.

[0050] In this example, a manganese dioxide catalyst was prepared by reducing potassium permanganate with ethanol on the surface of alumina pellets...

Embodiment 2

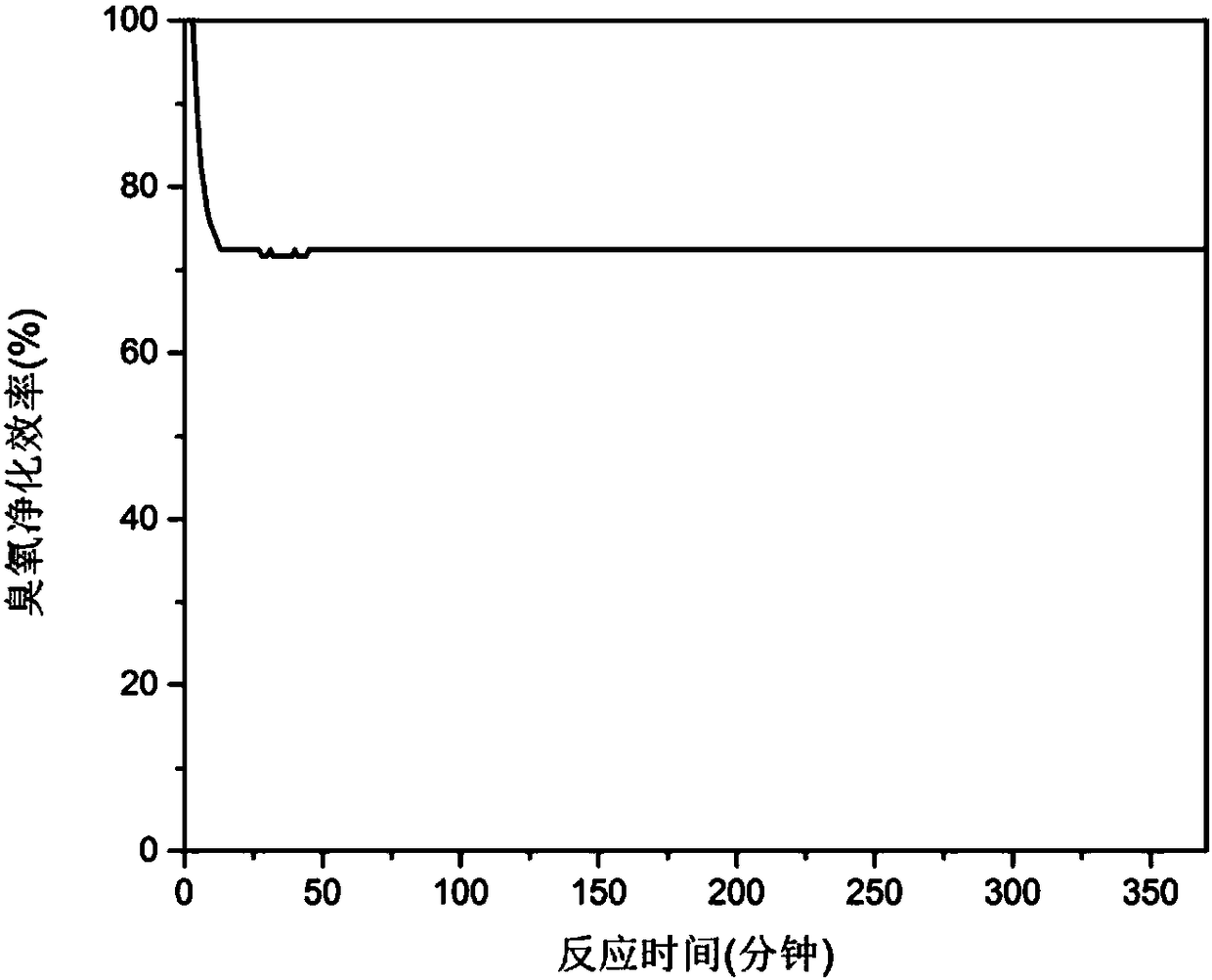

[0052] Weigh 3.16g of potassium permanganate and dissolve in 50mL of deionized water, take 150g of activated carbon particles with a particle size of 2-3mm and mix with the obtained solution, the potassium permanganate solution will completely wet the activated carbon particles and dry at 120°C; Dissolve 25mL of ethanol and 5mL of glacial acetic acid in 30mL of deionized water, then mix with the dried carrier, make the liquid fully infiltrate the carrier and stir, mix the solution with activated carbon particles, make the liquid fully infiltrate the carrier and stir, then put it in the oven The manganese precursor-coated regular support was obtained after removing excess water at a constant temperature of 60°C for 2 hours; the obtained support was placed in a muffle furnace, and the temperature was raised to 550°C at a rate of 5°C / min for calcination for 2.5h. The catalyst product was obtained after natural cooling.

[0053] In this example, a manganese dioxide catalyst was pr...

Embodiment 3

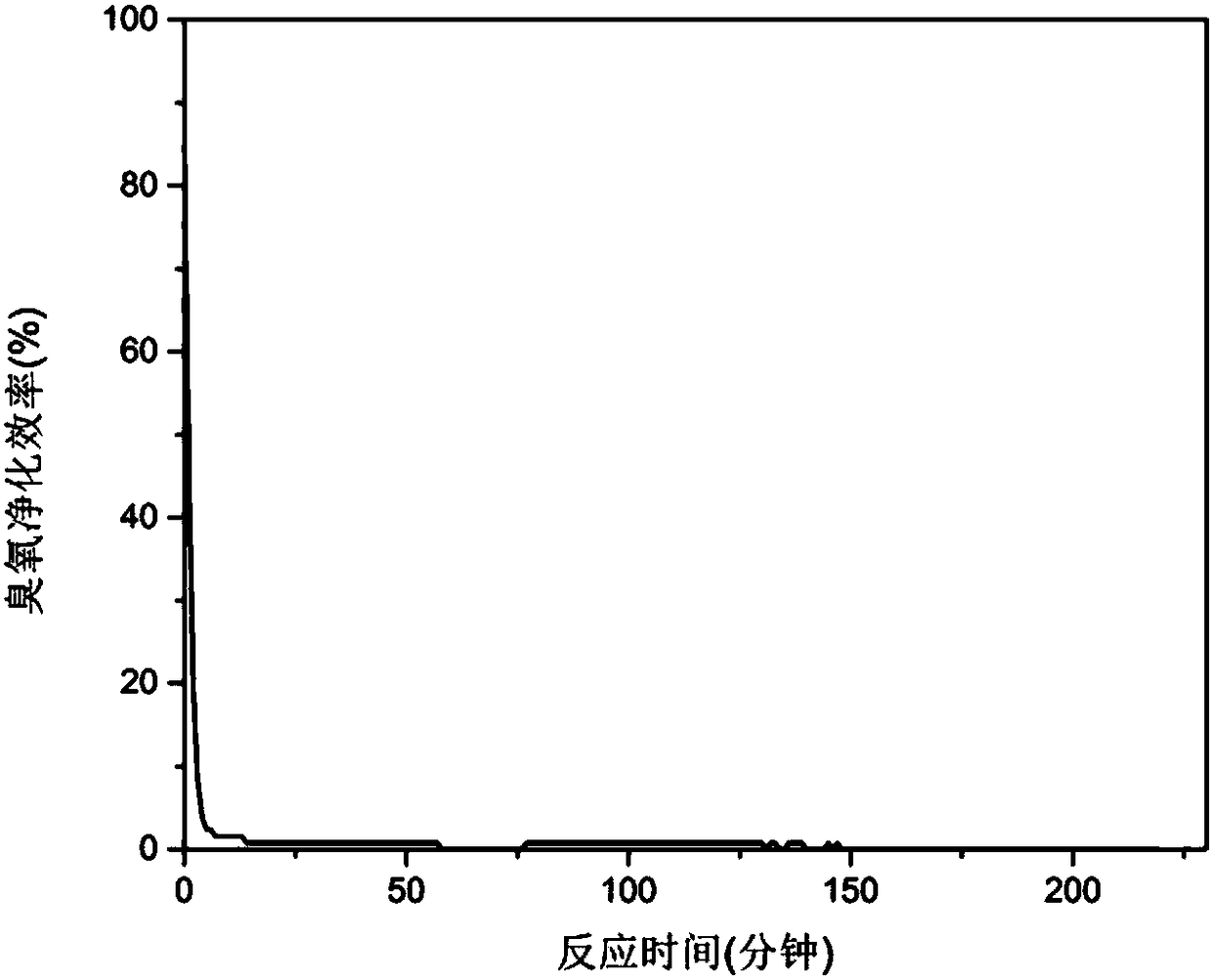

[0055] Weigh 6.76g of manganese sulfate and dissolve it in 50mL of deionized water, take 150g of alumina pellets with a particle size of 2-3mm and mix with the obtained solution, the manganese sulfate solution will completely wet the alumina pellets and dry them at 120°C; Dissolve 9.12g of ammonium persulfate, 5.28g of ammonium sulfate and 10g of potassium nitrate in 50mL of deionized water, then mix with the dried carrier, make the liquid fully infiltrate the carrier and stir, then put it in an oven at 50°C for constant temperature reaction 1h, the manganese precursor-coated regular support was obtained after removing excess water; the obtained support was placed in a muffle furnace, and the temperature was raised to 500°C at a rate of 5°C / min for calcination for 3h, and the catalyst product was obtained after natural cooling.

[0056] In this example, a manganese dioxide catalyst was prepared by oxidizing manganese sulfate on the surface of alumina pellets with ammonium persu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com