Eigen antiflaming semi-aromatic copolymerization aromatic ether amide and preparation method thereof

A technology of copolyaryl ether amide and intrinsic flame retardancy, which is applied in the field of synthetic flame-retardant polymer materials, can solve the problems of poor flame-retardant durability, migration of additives, poor compatibility between additives and substrates, etc., and achieve excellent flame retardancy , excellent mechanical properties, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (332g, 1mol) bis(4-fluorobenzoyl) butanediamine (BFBB), (212g, 2mol) sodium carbonate, 200ml toluene, (332.5g, 0.95mol) 9,9-bis(4-hydroxybenzene Base) fluorene (also known as bisphenol fluorene, FDP), (16.2g, 0.05mol) DOPO-HQ and 1500ml formamide were added to the reaction vessel, and then under the protection of nitrogen, dehydration reaction was carried out at a temperature of 175°C for 3h, and then at a temperature of 200°C React for 8 hours to obtain a viscous copolymer solution; then purify the copolymer solution, the specific steps are: cool the above solution to 120°C, pour it into water while stirring, and precipitate the gray thin strip polymer crude product; The mixture was washed with water and ethanol, dried at 80°C for 8 hours, pulverized, washed with deionized water and ethanol respectively, and dried at 80°C for 10 hours to obtain purified bisphenol fluorene copolymer polyarylether succinamide containing DOPO-HQ .

[0051] The intrinsic viscosity [η] of ...

Embodiment 2~4

[0053] The ratio of raw materials in the bisphenol fluorene copolymerized aryl ether succinamide prepared in Example 1 was adjusted to prepare bisphenol fluorene copolymerized aryl ether succinamide with different DOPO-HQ contents. The specific data are shown in Table 1.

[0054] Table 1

[0055]

Embodiment 5

[0057] (360g, 1mol) bis(4-fluorobenzoyl) hexamethylenediamine (BFBH), (276g, 2mol) potassium carbonate, 200ml p-xylene, (334.5g, 0.95mol) 4,4'-diphenylene Add methyl bisphenol (also known as bisphenol BP, DHTPM), (16.2g, 0.05mol) DOPO-HQ and 1500ml sulfolane into the reaction vessel, then dehydrate at 190°C for 1h under the protection of nitrogen, and then dehydrate at 200°C React for 12 hours to obtain a viscous copolymer solution. Cool the above solution to 80°C, pour it into water while stirring, and precipitate a gray thin strip polymer product; wash the above polymer with water and ethanol, and dry at 80°C for 8 hours , pulverized, washed with deionized water and ethanol respectively, and dried at 80° C. for 10 h to obtain purified bisphenol BP copolyaryl ether adipamide containing DOPO-HQ.

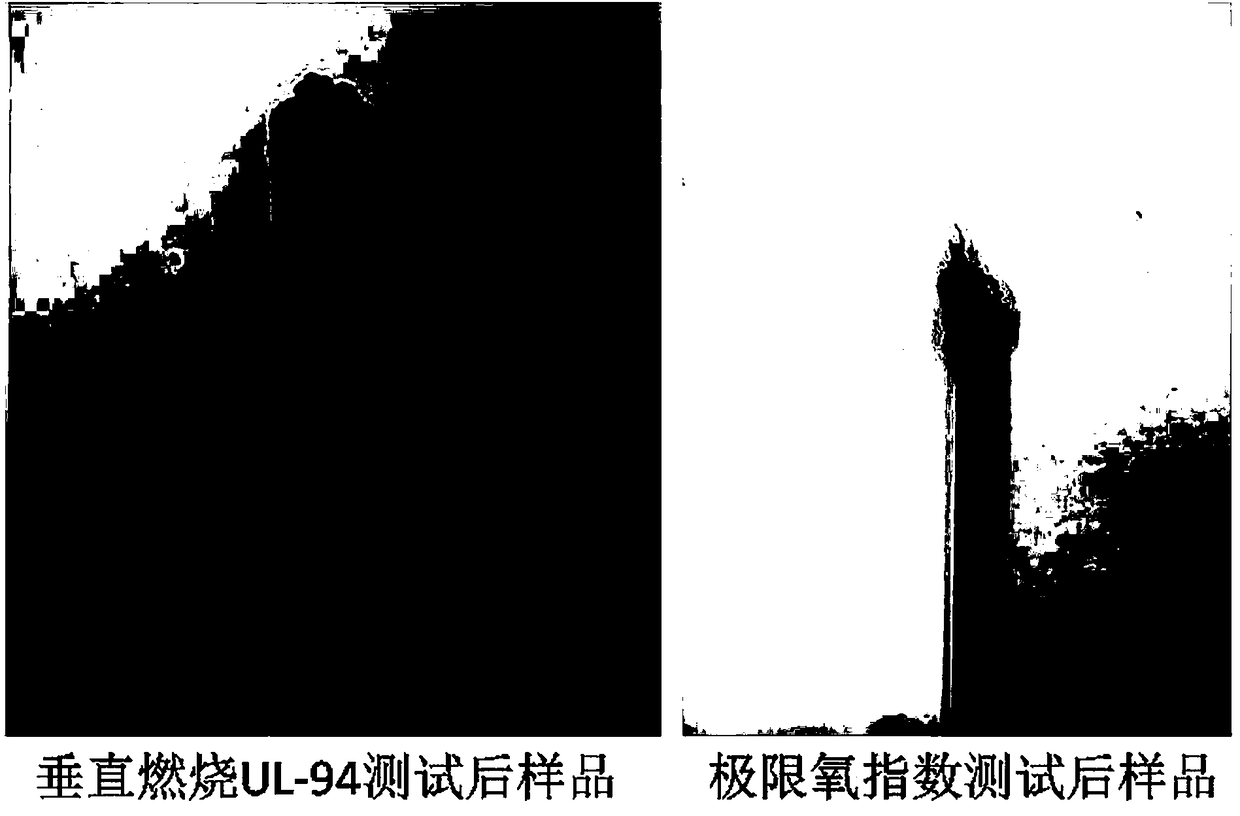

[0058] The intrinsic viscosity [η] of the copolyaryl ether adipamide is 0.82dL / g; the limiting oxygen index is 30.5%; the vertical burning grade is V-2, and the tensile strength is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com