Preparation method and application of quantum dot light emitting diode

A quantum dot light-emitting and diode technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of low luminous efficiency and luminous brightness, insufficient stability of QLED, and insufficient transportation balance. The effect of suppressing electron leakage, improving device performance, and stabilizing luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

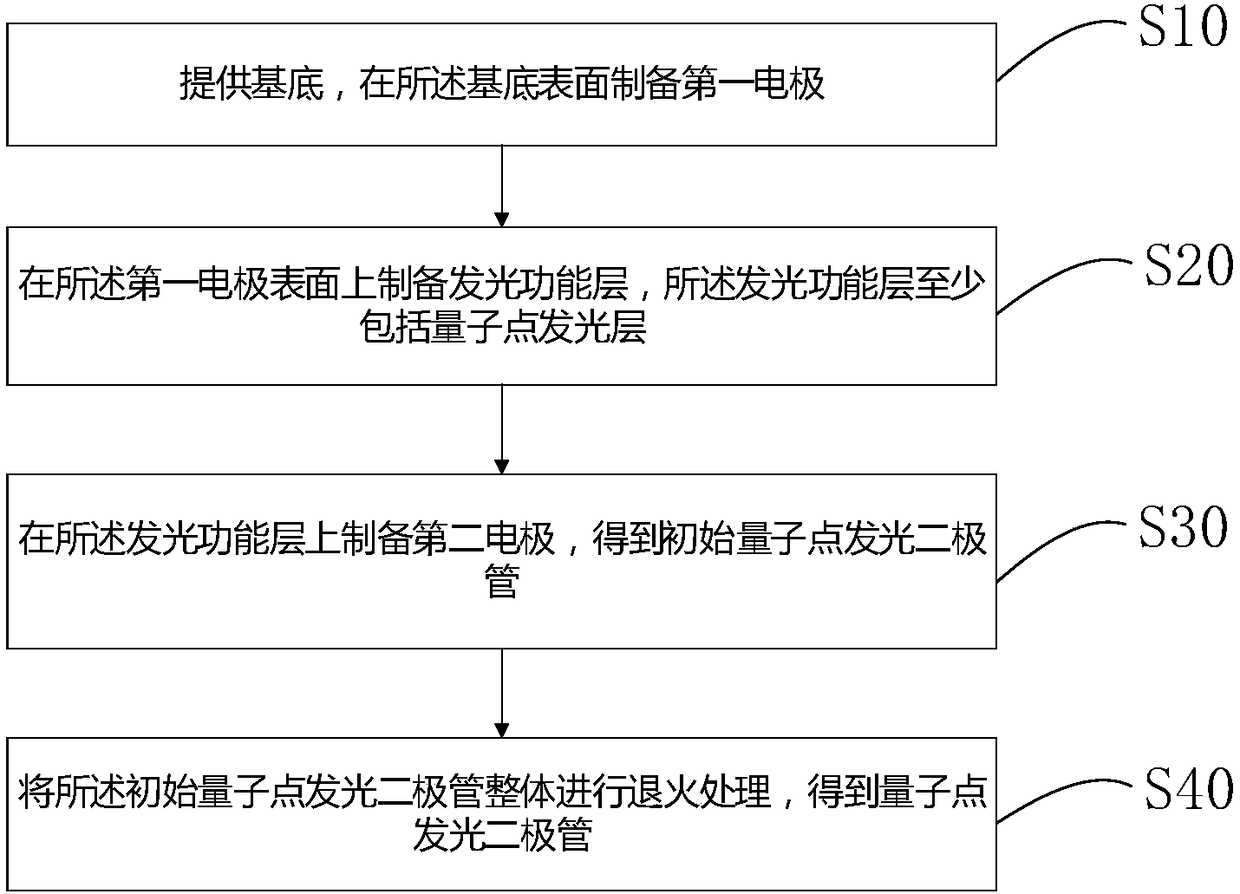

[0041] The invention provides a method for preparing a quantum dot light-emitting diode, such as figure 1 shown, including:

[0042] S10, providing a substrate, and preparing a first electrode on the surface of the substrate;

[0043] S20. Prepare a luminescent functional layer on the surface of the first electrode, the luminescent functional layer at least including a quantum dot luminescent layer;

[0044] S30, preparing a second electrode on the light-emitting functional layer to obtain an initial quantum dot light-emitting diode;

[0045] S40, annealing the entire initial quantum dot light emitting diode to obtain a quantum dot light emitting diode.

[0046] In the embodiment of the present invention, in S10, the material of the substrate includes one of glass, polyethylene, polypropylene, polystyrene, polylactic acid, polyethylene terephthalate, polyimide and polyurethane or more. The substrate can have a higher laser transmittance, so as to facilitate the smooth prog...

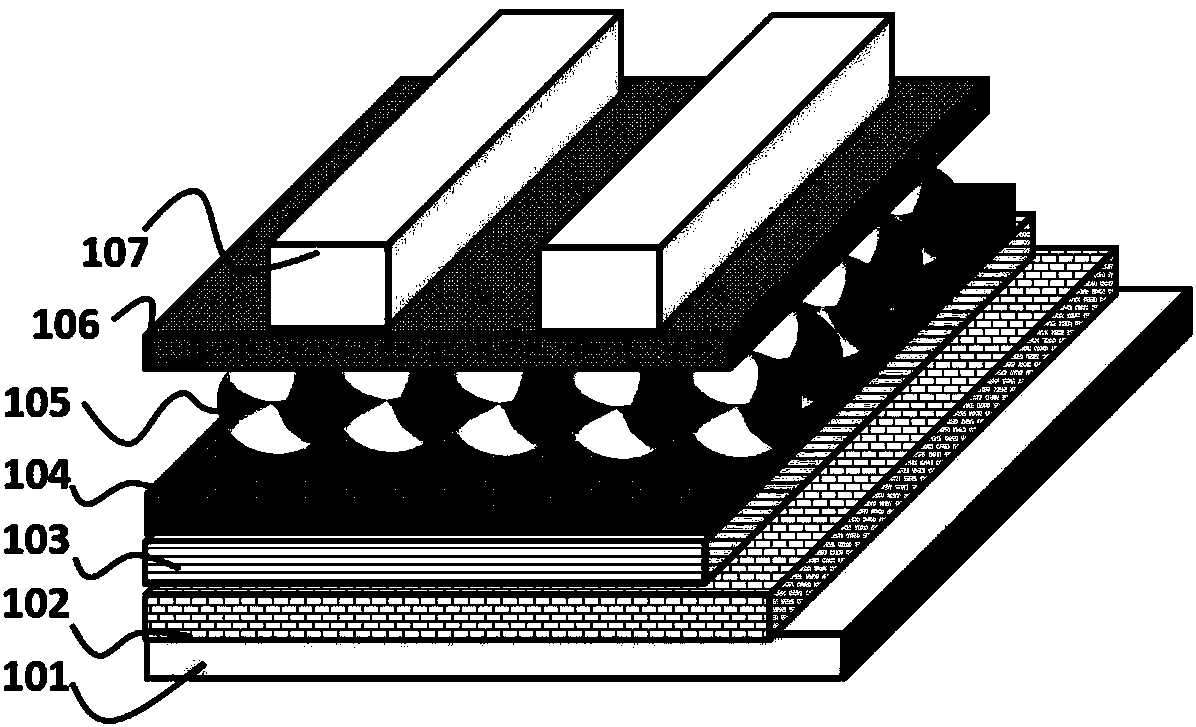

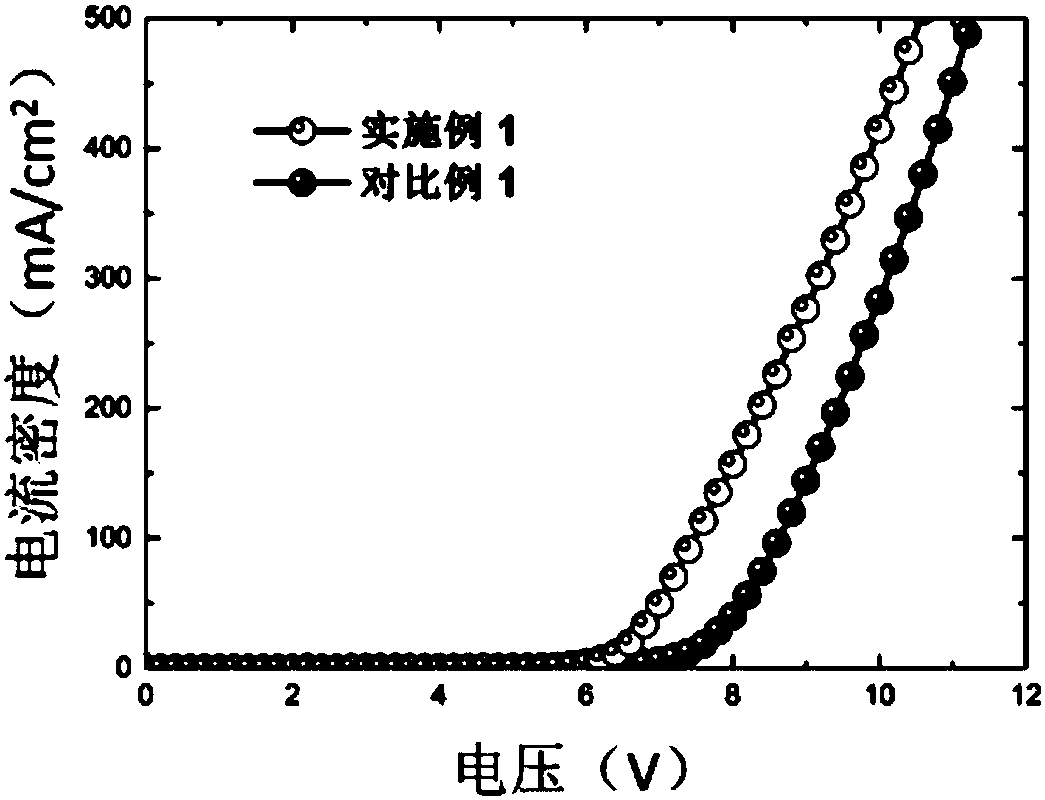

Embodiment 1

[0059] In this example, it is used to prepare a blue QLED device, wherein the quantum dot light-emitting layer includes blue quantum dot material, which is referred to as the blue light quantum dot light-emitting layer herein. Specifically, the structure of the blue QLED device is stacked sequentially from bottom to top: glass substrate, ITO thin film (first electrode), hole injection layer, hole transport layer, blue light quantum dot light emitting layer, electron transport layer and metal Electrode layer (second electrode). Concrete preparation steps include:

[0060] (1) Take the ITO glass substrate, use photolithography technology to make electrode patterns, and then place the substrate in lotion and deionized water for ultrasonic cleaning, ultrasonic cleaning three times, each ultrasonic time is 30min, after the ultrasonic cleaning is completed, Place the substrate in a clean oven to dry for later use.

[0061] (2) Treat the glass substrate with the ITO thin film on th...

Embodiment 2

[0085] This embodiment is used to prepare a green QLED device, wherein the quantum dot light-emitting layer includes a green light quantum dot material, which is referred to as a green light quantum dot light-emitting layer herein. Specifically, the structure of the green QLED device is sequentially stacked from bottom to top: a glass substrate, an ITO thin film (first electrode), a hole injection layer, a hole transport layer, a green quantum dot light-emitting layer, an electron transport layer and Metal electrode layer (second electrode). Concrete preparation steps include:

[0086] (1) Take the ITO glass substrate, use photolithography technology to make electrode patterns, and then place the substrate in lotion and deionized water for ultrasonic cleaning, ultrasonic cleaning twice, each ultrasonic time is 40min, after the ultrasonic cleaning is completed , place the substrate in a clean oven to dry for later use.

[0087] (2) Treat the glass substrate with the ITO thin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com