Sandwiched-structure composite metal lithium negative electrode and preparation method thereof

A composite metal, sandwich technology, applied in electrode manufacturing, structural parts, electrode rolling/calendering, etc., can solve the problem of difficult to achieve uniform mixing of metal lithium and composite, difficult to ensure batch reproducibility product consistency, difficult to achieve Large-scale production and other problems, to achieve the effect of improving lithium dendrite growth, reducing surface current density, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

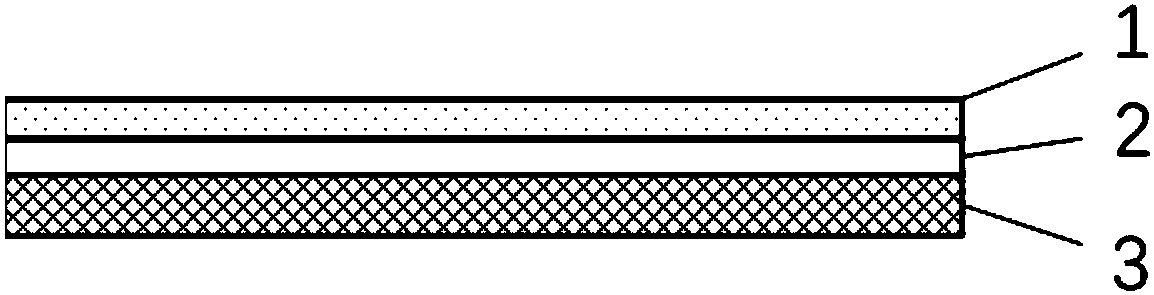

[0025] A method for preparing a composite metal lithium negative electrode with a sandwich structure provided by the present invention is characterized in that the method comprises the following steps:

[0026] 1) Dispersing the interface layer material in water or an organic solvent to prepare a slurry, the solid content of the slurry is preferably 3-10%;

[0027] The prepared slurry is evenly coated on the metal foil or diaphragm by a coating machine, and dried for use; a certain amount of binder can also be added between the slurry, and the interface layer material and the binder The mass ratio is preferably 1:0.01~0.4; the binder is usually one or more of polyvinylidene fluoride, sodium carboxymethyl cellulose and styrene-butadiene rubber; the organic solvent can be ethanol, iso One or more mixtures of propanol and N-methylpyrrolidone.

[0028] 2) Stack the current collector, the lithium strip, and the metal foil or separator coated with the interface layer material obtai...

Embodiment 1

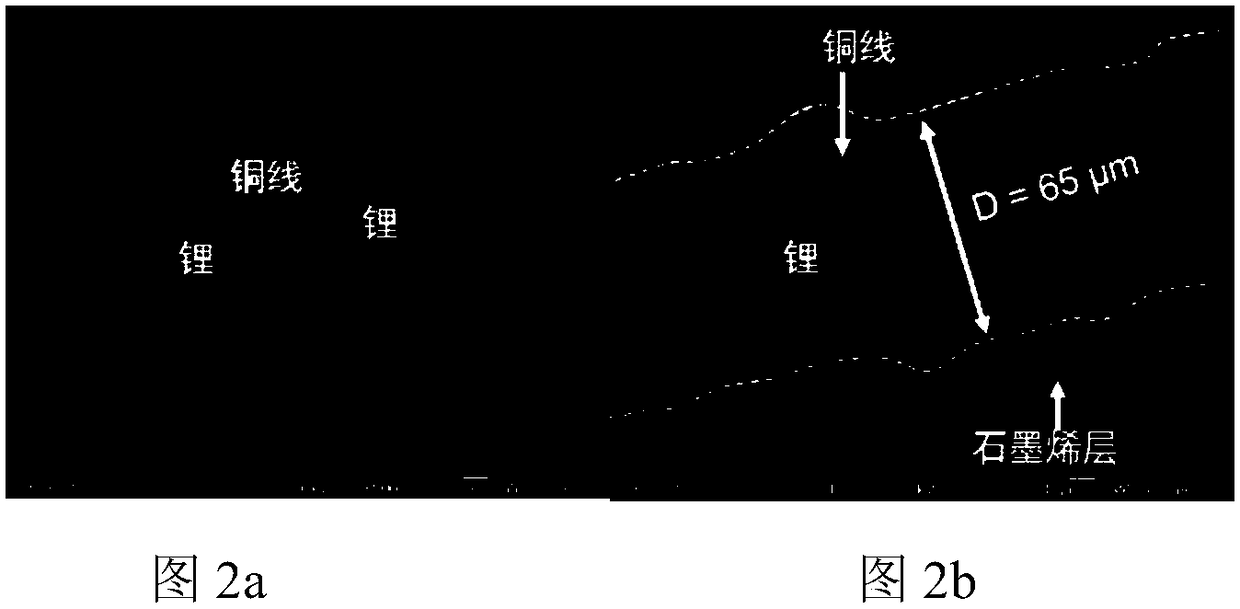

[0033] A copper mesh / lithium strip / graphene composite metal lithium negative electrode, the preparation process of which is as follows:

[0034] Mix graphene and polyvinylidene fluoride with a mass ratio of 1:0.4 evenly, then add N-methylpyrrolidone to prepare a slurry, the solid content of the slurry is 5%, and coat the slurry on the copper foil with a coating machine (referred to as carbon-coated copper foil), and placed in an oven at 90 degrees Celsius to dry for 2 hours for later use.

[0035] Copper mesh (400 mesh), lithium strip (50 μm), and carbon-coated copper foil are aligned and stacked (the carbon layer of the carbon-coated copper foil is placed toward the ultra-thin lithium strip), and rolled by a rolling mill.

[0036] After rolling, the copper foil on the upper layer of the sandwich structure is peeled off (the graphene layer sticks to the surface of the ultra-thin lithium strip after rolling), and finally a composite metal lithium negative electrode with a coppe...

Embodiment 2

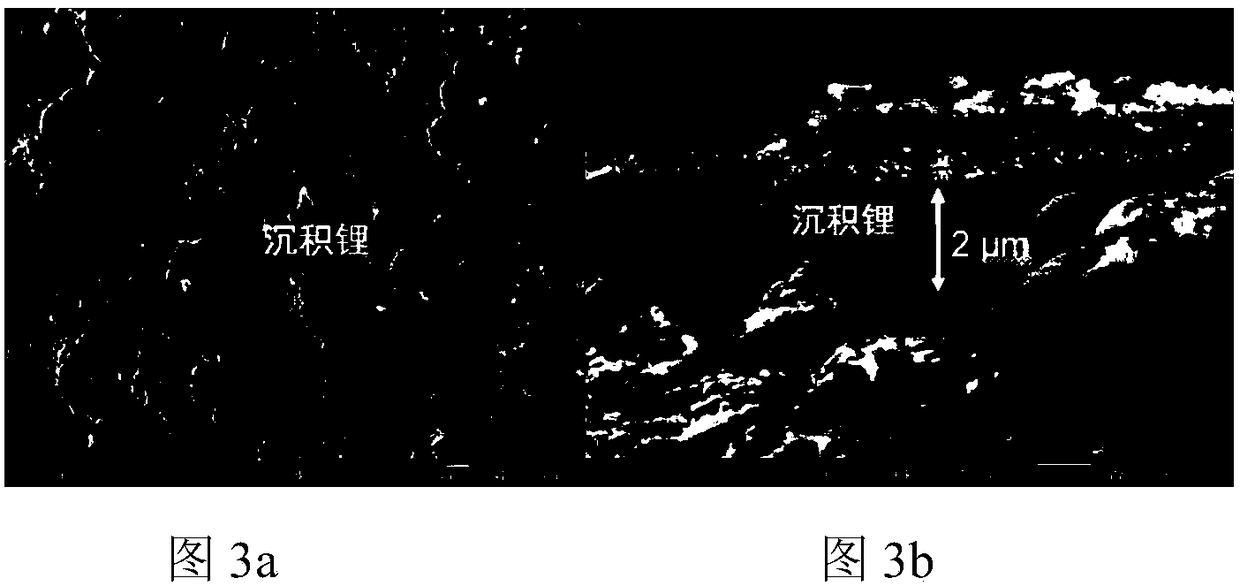

[0039] A copper foil / lithium strip / reduced graphene oxide (rGO) composite lithium metal negative electrode, the preparation process of which is as follows:

[0040]The mixture of reduced graphene oxide, sodium carboxymethyl cellulose and styrene-butadiene rubber with a mass ratio of 1:0.1 (the mass ratio of sodium carboxymethyl cellulose and styrene-butadiene rubber in the mixture is 1:1) was mixed evenly, and then super Pure water is prepared into a slurry, the solid content of the slurry is 5%, the slurry is coated on the diaphragm (referred to as carbon-coated diaphragm) with a coating machine, and placed in a vacuum oven at 60 degrees Celsius to dry for 6 hours for later use.

[0041] Copper foil, lithium strip (30 μm), and carbon-coated separator are aligned and stacked (the carbon layer of the carbon-coated separator is placed toward the ultra-thin lithium strip), and rolled by a rolling mill.

[0042] After rolling, the separator on the upper layer of the sandwich struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com