One-step preparation process for thin film composite membrane using dual (double layer)-slot coating technique

A separation membrane and thin film technology, applied in semi-permeable membrane separation, devices for coating liquid on the surface, membrane technology, etc., can solve the problems of increasing the risk of environmental pollution, increasing the cost of separation membrane preparation, and increasing the cost of preparation equipment, etc. Achieve the effect of saving the cost of preparation equipment, reducing the unit price of preparation, and saving the cost of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] 1. Materials

[0059] (a) PAN porous support

[0060] As the porous support, a polyacrylonitrile (PAN) support with a pore size of about 20 nm was used. The support body was hydrolyzed in 2M NaOH aqueous solution at 40° C. for 90 minutes to enhance the hydrophilicity and negative charge characteristics of the support body surface. It acts to enhance the adhesion between the formed selective layer and the porous support.

[0061] (b) Organic monomers and solvents for interfacial polymerization

[0062] As the first organic monomer and the first solvent for dissolving it, m-phenylenediamine (m-phenylenediamine, MPD) and water were respectively prepared, and 0.025, 0.05, 0.1 and 2% MPD aqueous solutions (first solution ).

[0063] Also, trimesoyl chloride (TMC) and hexane (n-hexane) were used as the second organic monomer and the second solvent for dissolving them, respectively, and a 0.1% TMC solution (second solution) was prepared.

[0064] 2. Preparation of Thin Fi...

Embodiment 1

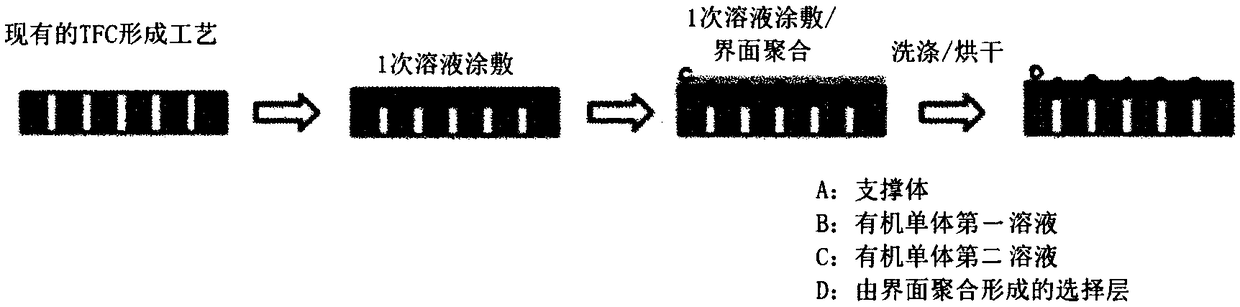

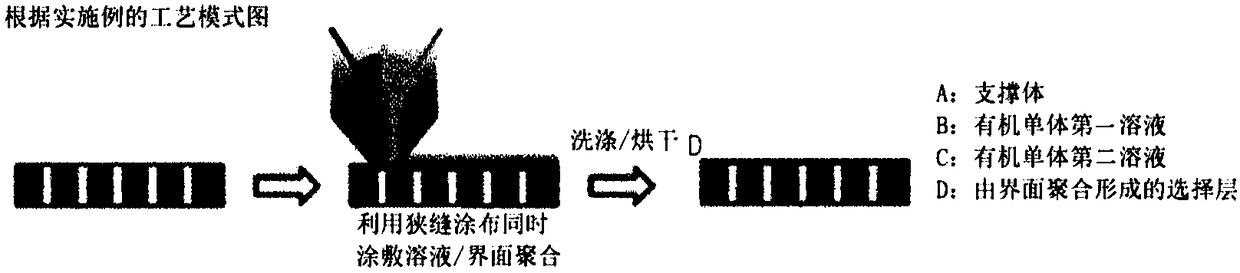

[0067] (2) Example 1. Thin film composite (TFC) separation membrane is prepared by a single-step preparation process (double (double layer)-slit coating technology)

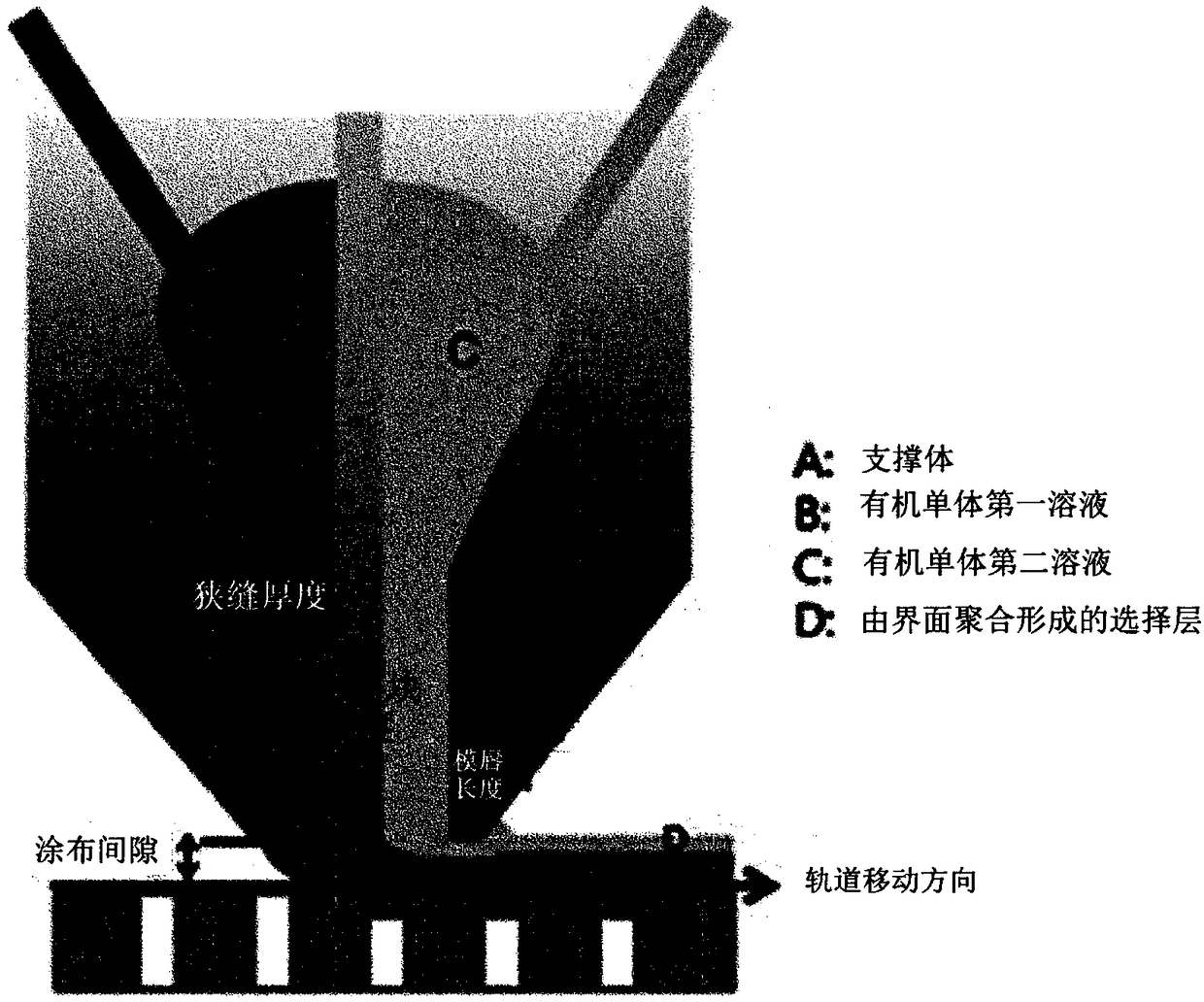

[0068] The PAN support was fixed on the track, and a thin-film composite separation membrane was prepared using a double-slot mold. In the present invention, image 3 and Figure 4 The shape of the double-slot die is shown.

[0069] After putting the aqueous MPD solution (first solution) and the TMC solution (second solution) into the double-slot die, the flow rates of the aforementioned aqueous MPD solution and TMC solution were stabilized. After the flow is stabilized, the double-slot mold is moved along the track at a certain speed, and the two solutions are simultaneously coated on the PAN support to form a double-layer solution layer. At this point, the selective layer is synthesized by interfacial polymerization within the bilayer solution layer. After the selection layer was prepared, it was washed wit...

experiment example 1

[0076] 3. Experimental example 1. Performance test

[0077] Using the same PAN support for the TFC separation membrane prepared by the method of Comparative Example 1 (2-step process) and the method of Example 1 (single-step process), the concentration of MPD aqueous solution (0.025, 0.05, 0.1 and 2% ) related performance.

[0078] Specifically, using a cross-flow filtration (Cross-flow filtration) device under normal temperature (25 ° C) and high pressure (15.5 bar (bar)) conditions, make 2000ppm of NaCl aqueous solution permeate the TFC separation membrane and measure the water permeability ( Water penetration rate) and salt (NaCl) removal rate.

[0079] The water permeability is calculated based on the amount of water permeated per unit area and per unit time of the separation membrane, while the NaCl removal rate is calculated by measuring the salt content of the feed solution and the permeate solution.

[0080] Table 3 below describes the performance evaluation results....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com