Preparation method of O-doped graphite phase carbon nitride nanosheet powder

A technology of graphite phase carbon nitride and nanosheets, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low photon efficiency of photogenerated electrons and holes, and achieve high specific surface area , Overcoming the effect of being extremely easy to quickly compound and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

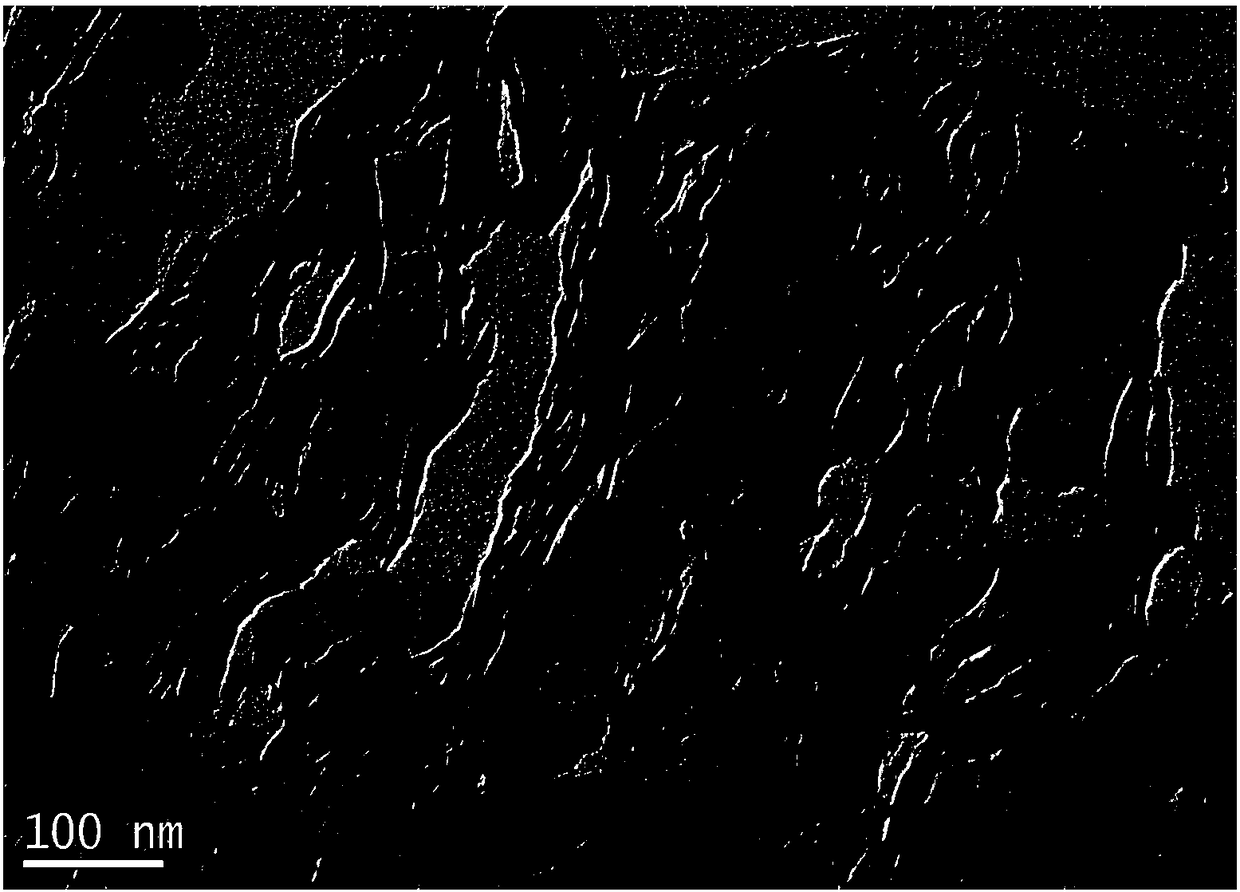

Image

Examples

Embodiment 1

[0032]Step 1, according to the mass ratio of melamine and deionization is 1:10, the volume ratio of hydrogen peroxide and deionized water with a mass concentration of 30% is 1:60, add melamine, hydrogen peroxide and deionized water to clean polytetrafluoroethylene Mix in the lining and stir evenly; put the above-mentioned polytetrafluoroethylene lining into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it warm at 140°C for 12h, and after cooling with the furnace, use the solid-liquid mixture obtained Ionized water and absolute ethanol were centrifugally washed three times respectively, and finally dried in an oven at 50°C for 36 hours to obtain the modified melamine precursor.

[0033] Step 2, put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 600°C for 2 hours, and calcine at a heating rate of 0.5°C / min to obtain O-doped g-C 3 N 4 powder.

[0034] The O-doped g-C obtained in this example 3 N 4 P...

Embodiment 2

[0036] Step 1, according to the mass ratio of melamine and deionized water is 1:1, and the volume ratio of hydrogen peroxide and deionized water with a mass concentration of 30% is 1:1, add melamine, hydrogen peroxide and deionized water to clean polytetrafluoroethylene Mix in the lining and stir evenly; put the above-mentioned polytetrafluoroethylene lining into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it at 180°C for 36h, and cool it with the furnace, and use the solid-liquid mixture obtained The modified melamine precursor can be obtained by centrifugally washing 6 times with deionized water and absolute ethanol, and finally drying in an oven at 90°C for 12 hours.

[0037] Step 2, put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 550°C for 3 hours, and calcine at a heating rate of 3°C / min to obtain O-doped g-C 3 N 4 powder.

[0038] The O-doped g-C obtained in this example 3 N 4 Powder T...

Embodiment 3

[0040] Step 1, according to the mass ratio of melamine and deionized water is 1:5, and the volume ratio of hydrogen peroxide and deionized water with a mass concentration of 30% is 1:10, add melamine, hydrogen peroxide and deionized water to clean polytetrafluoroethylene Mix in the lining and stir evenly; put the above-mentioned polytetrafluoroethylene lining into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it at 200°C for 24h, and cool it with the furnace, and use the solid-liquid mixture obtained The modified melamine precursor was obtained by centrifugally washing 4 times with ionized water and absolute ethanol, and finally drying in an oven at 70°C for 18 hours.

[0041] Step 2, put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 500°C for 6 hours, and calcine at a heating rate of 10°C / min to obtain O-doped g-C 3 N 4 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com