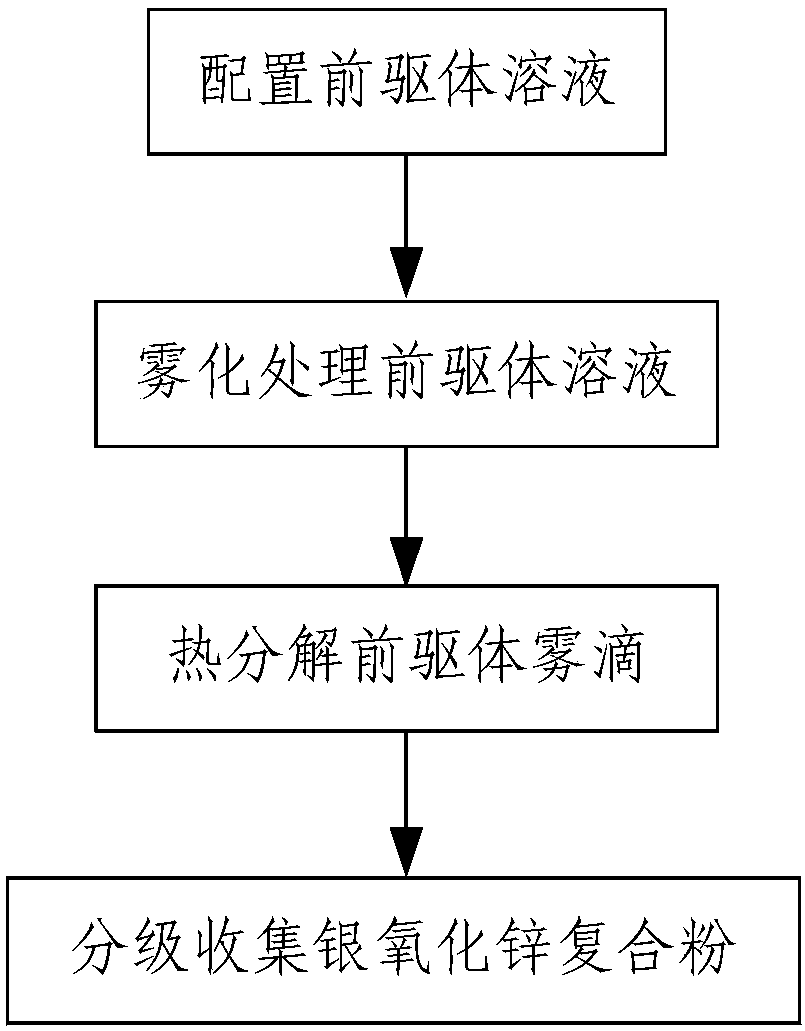

Preparation method and system for silver zinc oxide composite powder

A silver-zinc oxide and composite powder technology, which is applied in the field of preparation of silver-zinc oxide composite powder, can solve problems such as uneven surface and internal structure of finished materials, difficult control of powder quality stability, and inaccurate contact size, etc., to achieve product Phase control, large-scale mass production, and scientific and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

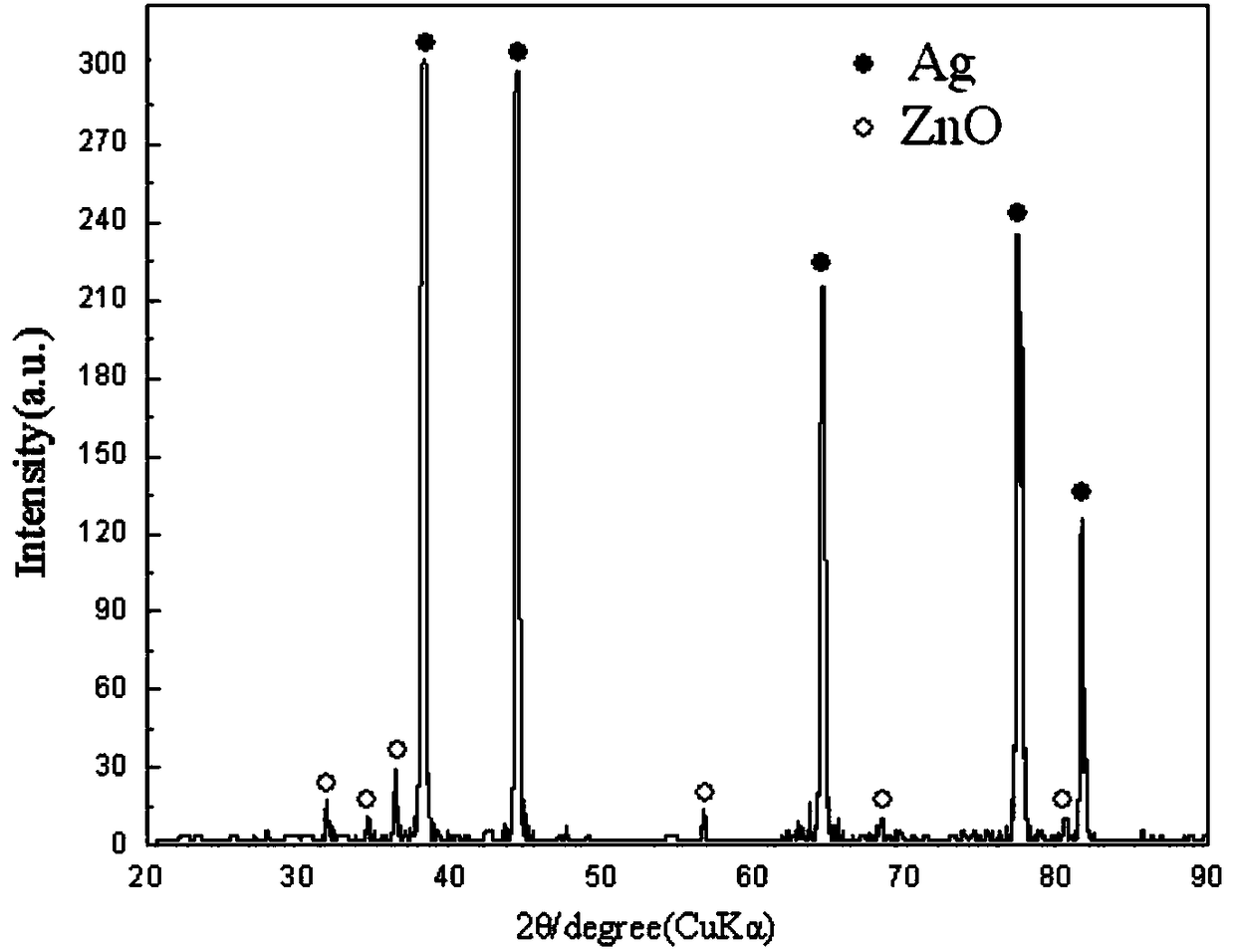

[0064] The embodiment of the present invention prepares silver-zinc oxide composite powder according to the above-mentioned preparation method, and the specific process is as follows: the molar ratio of zinc oxide and silver in the silver-zinc oxide composite powder product is preset to be 1:10, and the concentration of silver ions in the precursor solution is set to be 0.1mol / L, weigh 16.99g of silver nitrate and 2.98g of zinc nitrate hexahydrate according to the amount of 1L precursor solution, add 500ml of deionized water, ultrasonic vibration for 15min to dissolve, and finally constant volume to obtain a clear and transparent precursor solution .

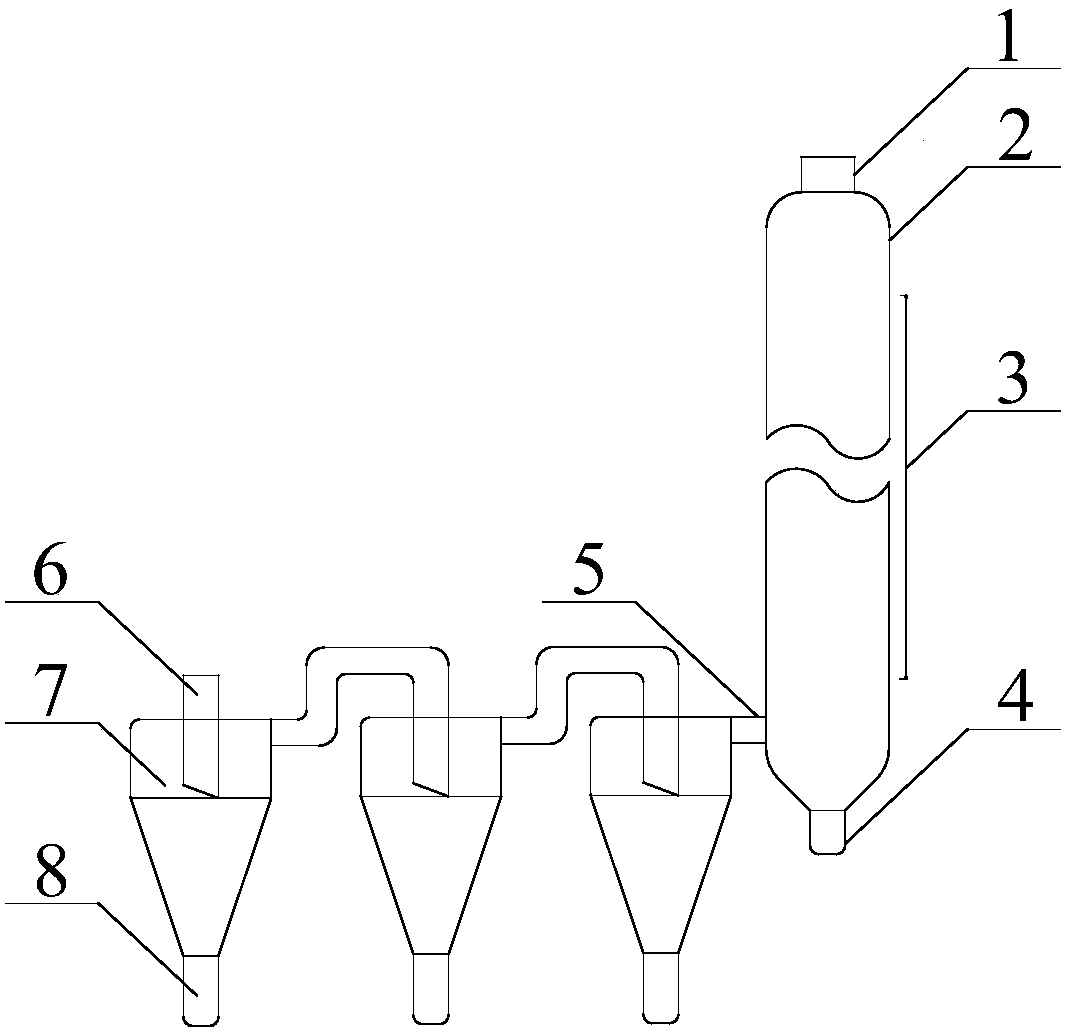

[0065] Subsequently, the temperature of the three constant temperature zones of the vertical resistance furnace was uniformly set to 600 °C, and the precursor solution was passed into the reaction furnace in the form of droplets through an ultrasonic atomization device. The compressed air flow rate was 15 L / min, and the droplet f...

Embodiment 2

[0068] The embodiment of the present invention prepares silver-zinc oxide composite powder according to the above-mentioned preparation method, the specific process is similar to that of Example 1, the difference is that when preparing the precursor solution, the concentration of silver ions in the precursor solution is controlled to be 0.2 mol / L, in addition, high temperature heating The temperature of the three constant temperature zones of the decomposed vertical resistance furnace is uniformly set to 1000°C, and the obtained silver-zinc oxide composite powder is collected by a cyclone classification device with a temperature of 200°C.

[0069] The results show that the prepared silver-zinc oxide composite powder is mainly Ag phase and ZnO phase, and the phases of the powder collected in the three receiving tanks are consistent; at the same time, the silver oxide collected in each receiving tank Scanning electron microscope analysis of the zinc composite powder shows that th...

Embodiment 3

[0071] The embodiment of the present invention prepares silver-zinc oxide composite powder according to the above-mentioned preparation method, the specific process is similar to that of Example 1, the difference is that when preparing the precursor solution, the molar ratio of zinc oxide and silver in the silver-zinc oxide composite powder product is preset. The ratio is 8:10. In addition, the temperature of the three constant temperature zones of the vertical resistance furnace for high-temperature pyrolysis is uniformly set to 900°C, and the obtained silver-zinc oxide composite powder is collected by a 200°C cyclone classifier.

[0072] The results show that the prepared silver-zinc oxide composite powder is mainly Ag phase and ZnO phase, and the phases of the powder collected in the three receiving tanks are consistent; at the same time, the silver oxide collected in each receiving tank Scanning electron microscope analysis of the zinc composite powder shows that the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com