Resistor disc for manufacturing piezoresistor with high discharge current capacity

A varistor and resistor chip technology, which is applied in the manufacture of resistor chips, varistors, varistor cores, etc., can solve the problem of high production cost, increased varistor application cost, and large varistor volume. and other problems, to achieve the effect of improving the anti-surge performance, reducing the application cost and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

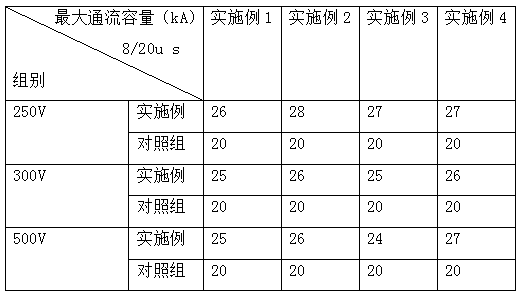

Examples

Embodiment 1

[0015] A resistance sheet for manufacturing a high-current capacity varistor. The ceramic sheet of the resistance sheet and the conductive electrode connected to it are covered with a protective layer. According to the mass parts, the ceramic sheet is prepared from the following raw materials: 150 parts of zinc oxide , 6 parts of bismuth oxide, 3 parts of antimony trioxide, 1 part of manganese dioxide, 0.5 part of cobalt trioxide, 4 parts of cobalt dioxide, 0.5 part of niobium pentoxide, 0.4 part of lanthanum oxide, 3 parts of strontium titanate, 13 parts of nano additives.

[0016] Nano-additives contain titanium oxide, lithium oxide, and nickel oxide.

[0017] The nano-additive needs to be modified before use. The method of modification is: add the nano-additive mixture into the reaction kettle filled with n-octanol solution and immerse it, raise the temperature in the reaction kettle to 80°C, and keep it warm for 2 hours. Then the solution is filtered off, and the precipit...

Embodiment 2

[0021] A resistance sheet for manufacturing high flow capacity varistors, the ceramic sheet of the resistance sheet and the conductive electrode connected to it are covered with a protective layer, and the ceramic sheet is prepared from the following raw materials in parts by mass: 180 parts of zinc oxide , 8 parts of bismuth oxide, 5 parts of antimony trioxide, 3 parts of manganese dioxide, 2 parts of cobalt trioxide, 8 parts of cobalt dioxide, 1 part of niobium pentoxide, 0.9 part of lanthanum oxide, 6 parts of strontium titanate, 15 parts of nano additives.

[0022] The nano additives contain nickel oxide, cadmium oxide and lead oxide.

[0023] The nano-additive needs to be modified before use. The method of modification is: add the nano-additive mixture into the reaction kettle filled with n-octanol solution and immerse it, raise the temperature in the reaction kettle to 120°C, and keep it warm for 4 hours. Then the solution is filtered off, and the precipitate is sent to...

Embodiment 3

[0027] A resistance sheet for manufacturing a high-current-capacity varistor. The ceramic sheet of the resistance sheet and the conductive electrode connected to it are covered with a protective layer. According to the mass parts, the ceramic sheet is prepared from the following raw materials: 170 parts of zinc oxide , 7 parts of bismuth oxide, 4 parts of antimony trioxide, 2 parts of manganese dioxide, 1 part of cobalt trioxide, 6 parts of cobalt dioxide, 0.7 part of niobium pentoxide, 0.6 part of lanthanum oxide, 5 parts of strontium titanate, 14 parts of nano additives.

[0028] Nano-additives contain titanium oxide, nickel oxide, cadmium oxide, and lead oxide.

[0029] The nano-additive needs to be modified before use. The method of modification is: add the nano-additive mixture into the reaction kettle filled with n-octanol solution and immerse it, raise the temperature in the reaction kettle to 100°C, and keep it warm for 3 hours. Then the solution is filtered off, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com