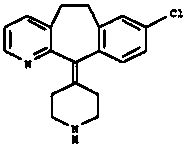

Purification method of crude product of desloratadine

A technique for desloratadine and a purification method, which is applied in the field of purification of crude desloratadine, can solve the problems of large product loss, long time consumption, and many impurities in the crude product, and achieve high product yield, shortened time, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 10 g of crude desloratadine into a 500 mL eggplant-shaped bottle, and add acetone-tetrahydrofuran (5:1) mixed solvent under heating at 40°C until the crude product is completely dissolved. Stop heating, let stand for crystallization overnight. Filter to get 8.9g desloratadine. HPLC analysis showed that the impurity content was 0.04%.

Embodiment 2

[0041] S10, at 40 DEG C, 10g desloratadine crude product is dissolved in the mixed solvent of 30mL ketone organic solvent and cyclic ether organic solvent; Wherein the volume ratio of ketone organic solvent and cyclic ether organic solvent is 4: 1;

[0042] S11, cooling to -6°C, filtering to obtain solid a and filtrate a;

[0043] S12. Heat the filtrate a to 40°C, stir for 20 minutes, cool down to -6°C, and filter to obtain solid b and filtrate b;

[0044] S13. At 40°C, solid a and solid b are combined and dissolved again with a mixed solvent of ketone organic solvent and cyclic ether / ester organic solvent;

[0045] S20. Naturally cool down to room temperature 20° C., precipitate crystal a, and filter the precipitated crystal a to obtain pure desloratadine.

[0046] Result: due to the low-temperature crystallization in steps S11~S12, the solid precipitation time is short, and the time required for crystallization in steps S11~S12 and step S20 is less than 3h, without overnig...

Embodiment 3

[0048] S10. Dissolve 100 g of crude desloratadine in 400 mL of a mixed solvent of ketone organic solvents and ester organic solvents at 50° C.; wherein the volume ratio of ketone organic solvents to cyclic ether organic solvents is 4:1 ;

[0049] S11, cooling to -3°C, filtering to obtain solid a and filtrate a;

[0050] S12. Warm up the filtrate a to 50°C, stir for 20 minutes, cool down to -3°C, and filter to obtain solid b and filtrate b;

[0051] S13. At 50°C, solid a and solid b are combined and dissolved again with a mixed solvent of ketone organic solvent and cyclic ether / ester organic solvent;

[0052] S20, cooling in an ice-water bath to precipitate crystal a, and filter the precipitated crystal a to obtain pure desloratadine.

[0053] Results: Due to the low-temperature crystallization in steps S11~S12, the time for solid precipitation is short, and the time required for crystallization in steps S11~S12 and step S20 is less than 5 hours, without overnight, the time f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com