Silicone rubber impression material and preparation method

A silicone rubber and impression material technology, applied in the fields of medical materials and dental medical materials, can solve problems such as affecting the accuracy of the negative mold in clinical operation, affecting the mixing and curing process of materials, and being unfavorable to control cross-infection, so as to achieve control of cross-infection. , The effect of small deformation and light release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

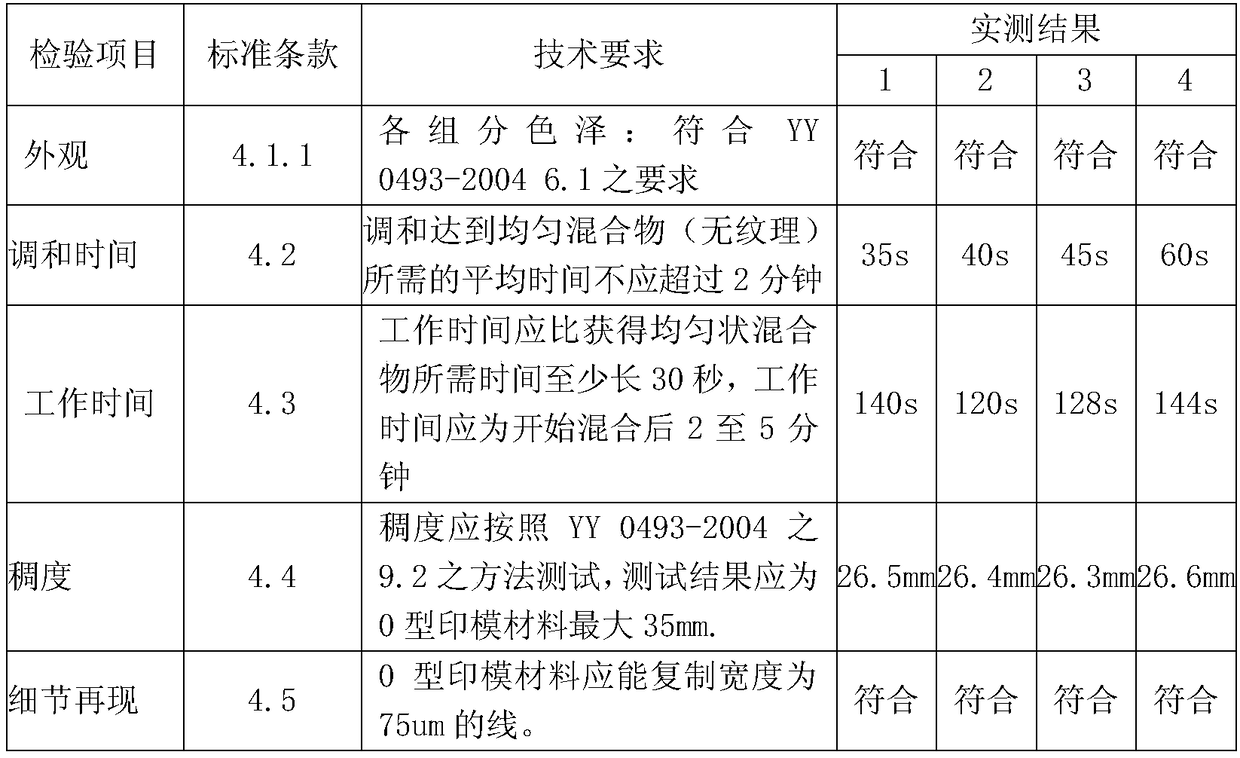

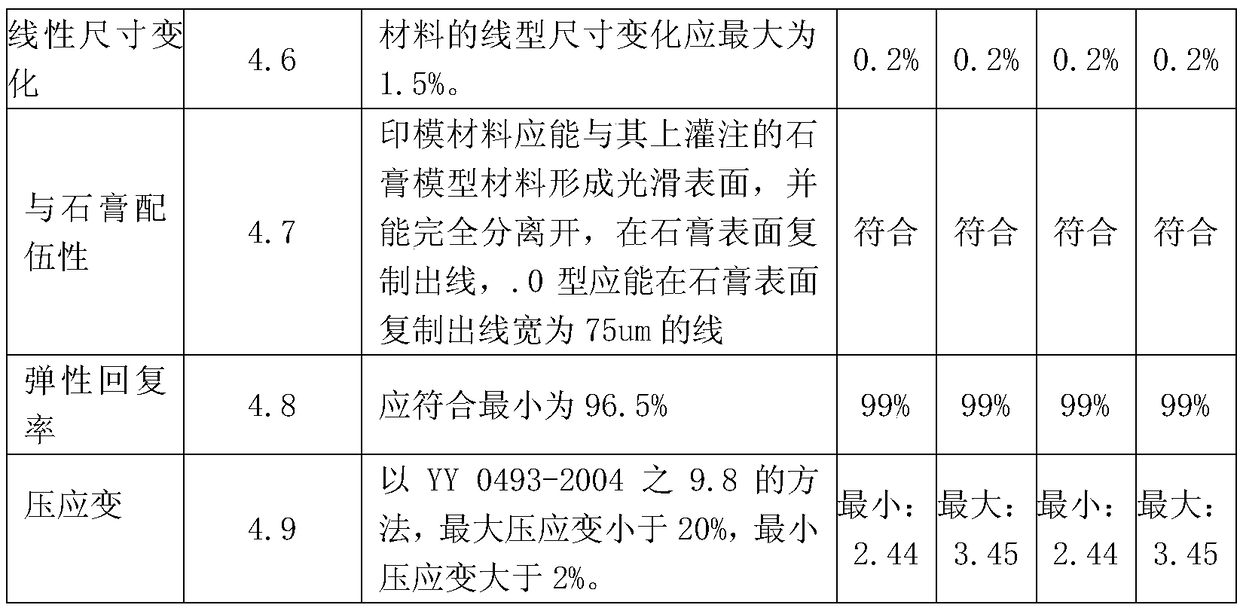

Examples

Embodiment 1

[0047] 1. Preparation of filler

[0048] 1.1. Synthesis of vinyl silicone oil

[0049] 37 parts of octamethylcyclotetrasiloxane, 40 parts of divinyltetramethyldisiloxane and 0.75 parts of catalyst were synthesized under vacuum conditions at 60°C to obtain a variety of different viscosities with different vinyl content and higher vinyl content. Active vinyl silicone oil, after testing, the vinyl content in the prepared vinyl silicone oil is 75%.

[0050] Wherein, the catalyst is a general catalyst for synthesizing vinyl silicone oil, such as tetramethylammonium hydroxide.

[0051] 1.2. Preparation of filler

[0052] Take 40 parts of the vinyl silicone oil prepared in step 1.1, add 4 parts of white carbon black into it after vaporization, and use a high-speed disperser to evenly disperse the fumed white carbon black into the vinyl silicone oil, and finally add 36 parts of silicon Azane coupling agents are mixed to form fillers.

[0053]The white carbon black used in the pres...

Embodiment 2

[0070] 1. Preparation of filler

[0071] 1.1. Synthesis of vinyl silicone oil

[0072] 30 parts of octamethylcyclotetrasiloxane, 50 parts of divinyltetramethyldisiloxane and 4 parts of catalyst were synthesized under vacuum conditions at 80°C to obtain a variety of different viscosities with different vinyl content and higher vinyl content. Active vinyl silicone oil, after testing, the vinyl content in the prepared vinyl silicone oil is 70%.

[0073] 1.2. Preparation of filler

[0074] Take 30 parts of the vinyl silicone oil prepared in step 1.1, add 3.6 parts of white carbon black into the gas phase, and use a high-speed disperser to evenly disperse the gas phase white carbon black into the vinyl silicone oil, and finally add 50 parts of silicon Azane coupling agents are mixed to form fillers.

[0075] 2. Preparation of the first component

[0076] 2.1. Synthesis of hydrogen-containing silicone oil

[0077] 32 parts of octamethylcyclotetrasiloxane, 18 parts of hydrogen-c...

Embodiment 3

[0088] 1. Preparation of filler

[0089] 1.1. Synthesis of vinyl silicone oil

[0090] 40 parts of octamethylcyclotetrasiloxane, 38 parts of divinyltetramethyldisiloxane and 3 parts of catalyst were synthesized under vacuum conditions at 70°C to obtain a variety of different viscosities with different vinyl content and higher vinyl content. Active vinyl silicone oil, after testing, the vinyl content in the prepared vinyl silicone oil is 65%.

[0091] 1.2. Preparation of filler

[0092] Take 60 parts of the vinyl silicone oil prepared in step 1.1, add 20.8 parts of white carbon black into it after vaporization, and use a high-speed disperser to evenly disperse the fumed white carbon black into the vinyl silicone oil, and finally add 38 parts of silicon Azane coupling agents are mixed to form fillers.

[0093] 2. Preparation of the first component

[0094] 2.1. Synthesis of hydrogen-containing silicone oil

[0095] 38 parts of octamethylcyclotetrasiloxane, 22 parts of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com