Heteroatom doping porous carbon materials and preparation method thereof

A technology of porous carbon materials and heteroatoms, applied in the field of heteroatom doped porous carbon materials and its preparation, can solve the instability between batches, non-environmentally friendly strong alkali sodium hydroxide, and limit practical application prospects and other problems, to achieve the effect of no capacity attenuation, good industrialization prospects, and low equipment and operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

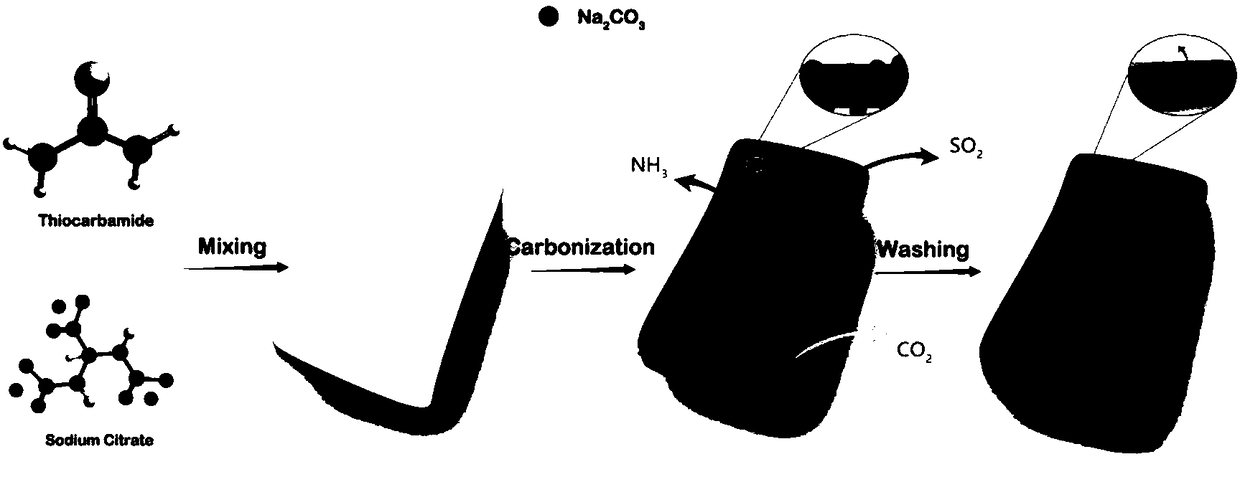

[0065] 1. A method for preparing a heteroatom-doped porous carbon material, comprising the steps of:

[0066] 1) Weigh 10g of potassium citrate dihydrate and 0.5g of urea, put them into a mortar and grind evenly until there is no obvious graininess, put the ground mixture in a corundum boat with a size of 10cm*4cm*2cm, and then put the corundum The boat was placed in a tube furnace with a quartz tube diameter of 5 cm. Under the protection of argon, the temperature was raised to 700 °C at a rate of 5 °C / min, kept for 1 hour, and naturally cooled to room temperature to obtain a powder;

[0067] 2) Put the powder obtained in step 1) in a mortar and grind it evenly until there is no obvious graininess, then soak the powder in deionized water and stir for 6 hours according to the ratio of powder and deionized water: 0.1g:50mL, Then vacuum suction filtration, after suction filtration, clean the powder with deionized water and absolute ethanol; repeat the above soaking, ultrasonic, s...

Embodiment 2

[0073] 1. A method for preparing a heteroatom-doped porous carbon material, comprising the steps of:

[0074] 1) Weigh 10g of sodium citrate dihydrate and 1g of thiourea, put them into a mortar and grind evenly until there is no obvious graininess, put the ground mixture in a corundum boat with a size of 10cm*4cm*2cm, and then put the corundum The boat was placed in a tube furnace with a quartz tube diameter of 5 cm. Under the protection of nitrogen, the temperature was raised to 700 °C at a rate of 4 °C / min, kept for 1 h, and naturally cooled to room temperature to obtain a powder;

[0075] 2) Put the powder obtained in step 1) in a mortar and grind it evenly until there is no obvious graininess, and then soak the powder in deionized water for 30 minutes according to the ratio of powder and deionized water: 1g: 1000mL, Then vacuum suction filtration, after suction filtration, clean the powder with deionized water and absolute ethanol; repeat the above soaking, ultrasonic, suc...

Embodiment 3

[0081] 1. A method for preparing a heteroatom-doped porous carbon material, comprising the steps of:

[0082] 1) Weigh 10g of sodium gluconate and 10g of urea, put them into a mortar and grind them evenly until there is no obvious graininess, put the ground mixture in a nickel boat with a size of 10cm*4cm*2cm, and then put the nickel boat in In a tube furnace with a quartz tube diameter of 5 cm, under the protection of nitrogen, the temperature was raised to 400 °C at a rate of 2 °C / min, kept for 5 hours, and naturally cooled to room temperature to obtain a powder;

[0083] 2) Put the powder obtained in step 1) in a mortar and grind it evenly until there is no obvious graininess, then soak the powder in deionized water and stir for 10 hours according to the ratio of powder and deionized water: 1g: 1200mL, and then Vacuum suction filtration, after suction filtration, wash the powder with deionized water and absolute ethanol; repeat the above soaking, ultrasonication, suction fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com