Special amino modified perfluorosulfonic membrane for fuel cell, and preparation method

A perfluorosulfonic acid membrane, amino-modified technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of large dependence on external moisture content control, branch length, limited use, etc., to improve proton adsorption and migration. Ability, high structural symmetry, high feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

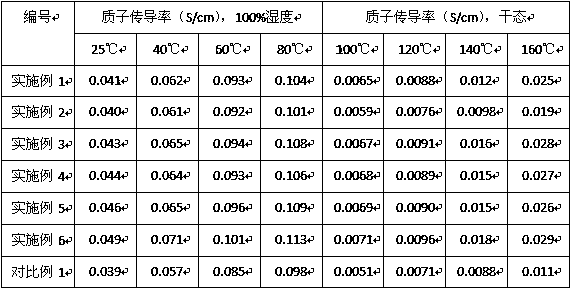

Examples

Embodiment 1

[0040] The following method was used to prepare the amino-modified perfluorosulfonic acid membrane for fuel cells:

[0041] a. Sulfonation of tetrafluoroethylene: Add sulfuric acid in a closed container, vacuumize it to make the pressure below 10Pa, then pass tetrafluoroethylene into it, and heat to react. The reaction temperature is 600°C, the pressure is 3MPa, and the reaction is 20h After that, get COFCF 2 SO 2 F;

[0042] b. Fluorination of 3-aminopropene: Under the condition of excluding oxygen, fluorinate 3-aminopropene to obtain CF 2 CFCF 2 NF 2 ; The fluorinating reagent used for fluorination is a mixed gas of fluorine and nitrogen, and the volume percentage of fluorine in the mixed gas is more than 30%; and the molar ratio of 3-aminopropene to fluorine is 1:10;

[0043] c, condensation reaction: the COFCF of step a 2 SO 2 CF for steps F and b 2 CFCF 2 NF 2 Put it in a closed container, and react under high temperature and high pressure for 10 hours to obtain...

Embodiment 2

[0050] The following method was used to prepare the amino-modified perfluorosulfonic acid membrane for fuel cells:

[0051] a. Sulfonation of tetrafluoroethylene: Add sulfuric acid in a closed container, vacuumize to make the pressure below 10Pa, then pass through tetrafluoroethylene, and heat to react. The reaction temperature is 800°C, the pressure is 6MPa, and the reaction is 10h After that, get COFCF 2 SO 2 F;

[0052] b. Fluorination of 3-aminopropene: Under the condition of excluding oxygen, fluorinate 3-aminopropene to obtain CF 2 CFCF 2 NF 2 ; The fluorinating reagent used for fluorination is a mixed gas of fluorine and nitrogen, the volume ratio of fluorine and nitrogen in the mixed gas is 1:1; and the molar ratio of 3-aminopropene to fluorine is 1:5;

[0053] c, condensation reaction: the COFCF of step a 2 SO 2 CF for steps F and b 2 CFCF 2 NF 2 Put it in a closed container, and react under high temperature and high pressure for 15 hours to obtain a modifie...

Embodiment 3

[0058] The following method was used to prepare the amino-modified perfluorosulfonic acid membrane for fuel cells:

[0059] a. Sulfonation of tetrafluoroethylene: add sulfuric acid in a closed container, vacuumize it to make the pressure below 10Pa, then pass tetrafluoroethylene into it, and heat to react. The reaction temperature is 700°C, the pressure is 4MPa, and the reaction is 12h After that, get COFCF 2 SO 2 F;

[0060] b. Fluorination of 3-aminopropene: Under the condition of excluding oxygen, fluorinate 3-aminopropene to obtain CF 2 CFCF 2 NF 2 ; The fluorinating reagent used for fluorination is a mixed gas of fluorine and nitrogen, the volume ratio of fluorine and nitrogen in the mixed gas is 2.5:1; and the molar ratio of 3-aminopropene to fluorine is 1:9;

[0061] c, condensation reaction: the COFCF of step a 2 SO 2 CF for steps F and b 2 CFCF 2 NF 2 Put it in a closed container, and react under high temperature and high pressure for 12 hours to obtain a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com