Antenna structure for terahertz microbolometer and preparation method thereof

A microbolometer and antenna structure technology, applied in the field of terahertz detection and imaging, can solve the problems of high absorption rate in difficult wide frequency bands, low absorption rate of metal films, etc. Effective absorption area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In order to solve the problem that the metal thin film in the common microbridge structure in the existing terahertz microbolometer has a low absorption rate, but the antenna absorption structure has frequency selectivity, and it is difficult to obtain a high absorption rate in a wide frequency band, the present invention provides a An antenna structure for a terahertz microbolometer and a preparation method thereof.

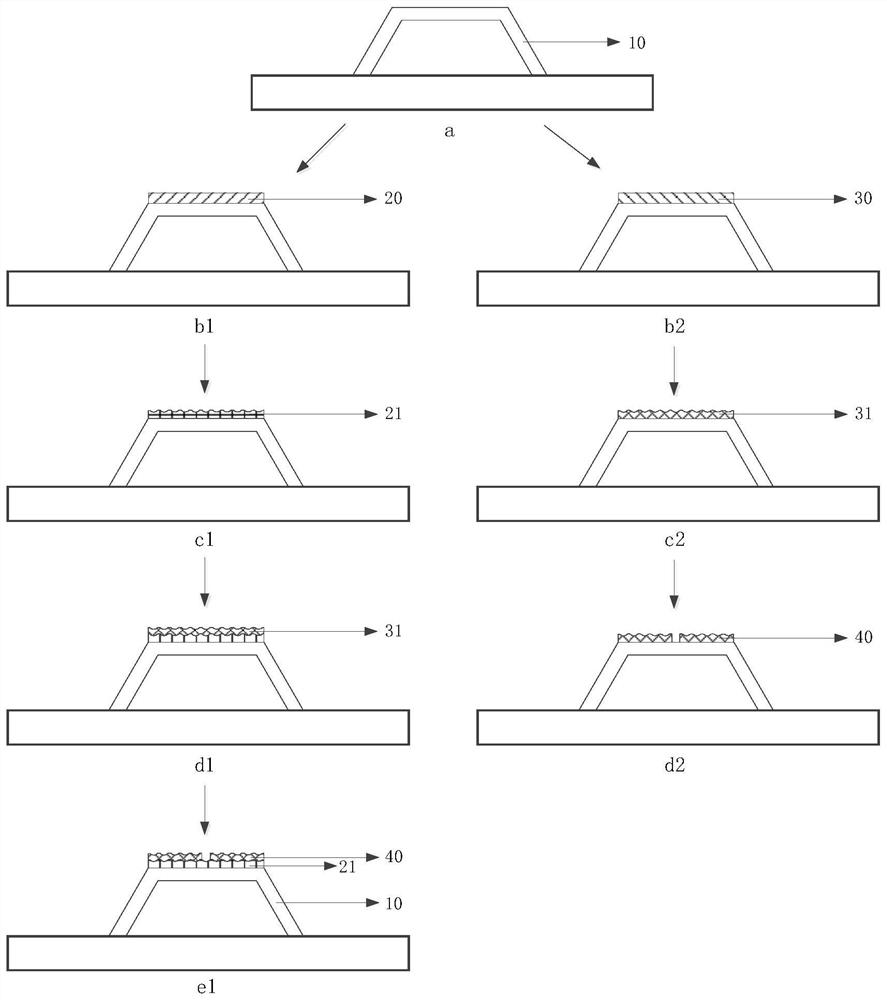

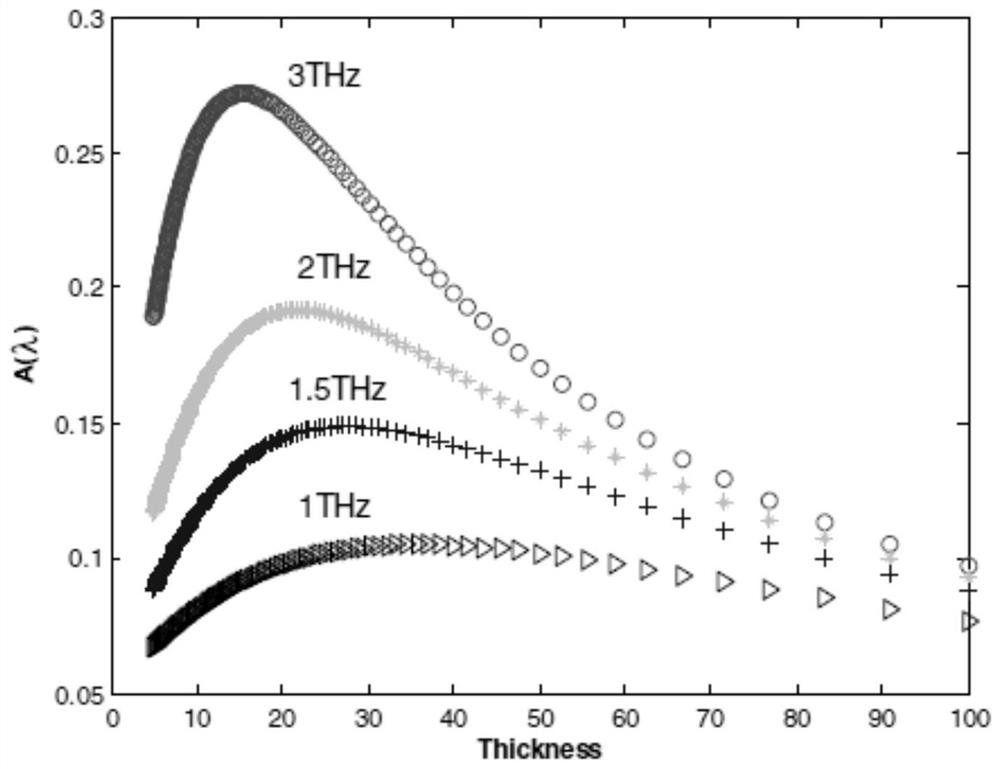

[0045] An antenna structure for a terahertz microbolometer, the antenna structure 40 is a planar antenna structure located in a multilayer film on the bridge deck of a terahertz microbolometer microbridge structure 10, and the antenna structure 40 has a thickness of 5-40nm metal thin film. The antenna structure 40 of the present invention integrates a layer of planar antenna in the multilayer film of the terahertz microbolometer microbridge structure bridge deck. The antenna structure has a large metal film area and is used as a metal film absorption laye...

Embodiment 1

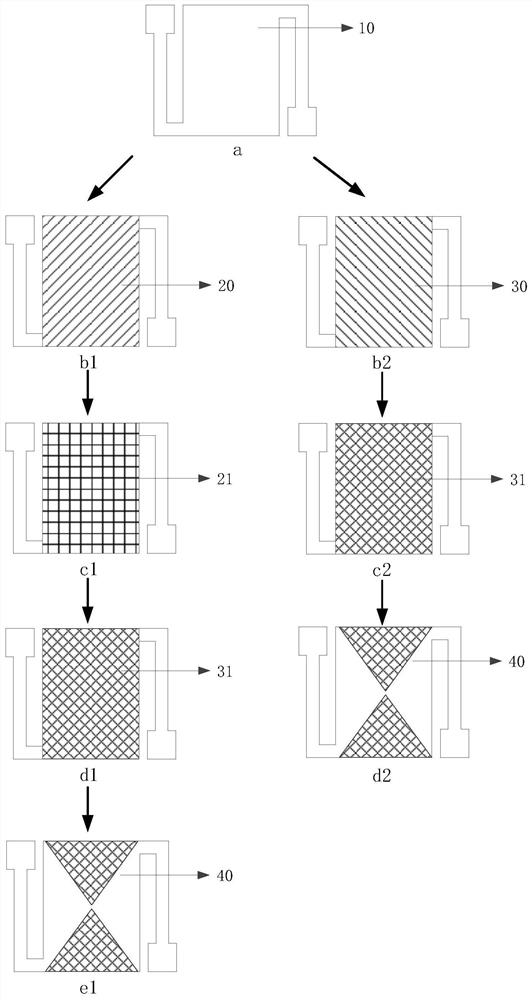

[0059] A RIE modified antenna structure for terahertz microbolometers, the preparation process is as follows figure 1 shown.

[0060] Terahertz microbolometer microbridge structure such as figure 1 Shown in a. Clean the surface of the micro-bridge structure, remove the contamination of the interface of the sensitive layer of the bridge deck and the interface of the substrate circuit, and bake the substrate at 200°C to remove the moisture on the surface.

[0061] The silicon nitride dielectric film was prepared by PECVD growth technology, the PECVD deposition temperature was 250°C, and the SiH 4 with NH 3 The flow ratio is 30 / 150, and the thickness of the prepared silicon nitride film is 200nm, such as figure 1 Shown in b1.

[0062] The silicon nitride film is etched through the first reactive ion etching process to form a surface microstructure. Etching gas is CHF 3 and O 2 . set CHF 3 with O 2 The flow ratio is 20:5, the RF power is 400W, the reaction chamber pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com