Hydrogen-evolution electrocatalytic material and preparation method thereof

An electrocatalytic material and hydrogen evolution technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as poor stability, low catalytic efficiency, and few active sites, and achieve high stability and catalytic activity High, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

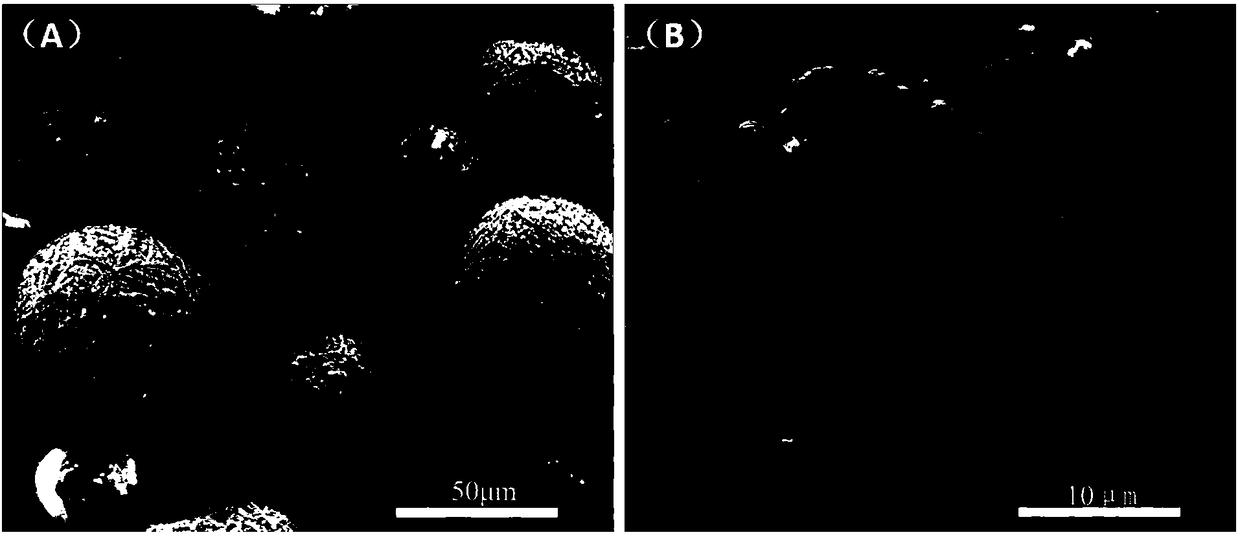

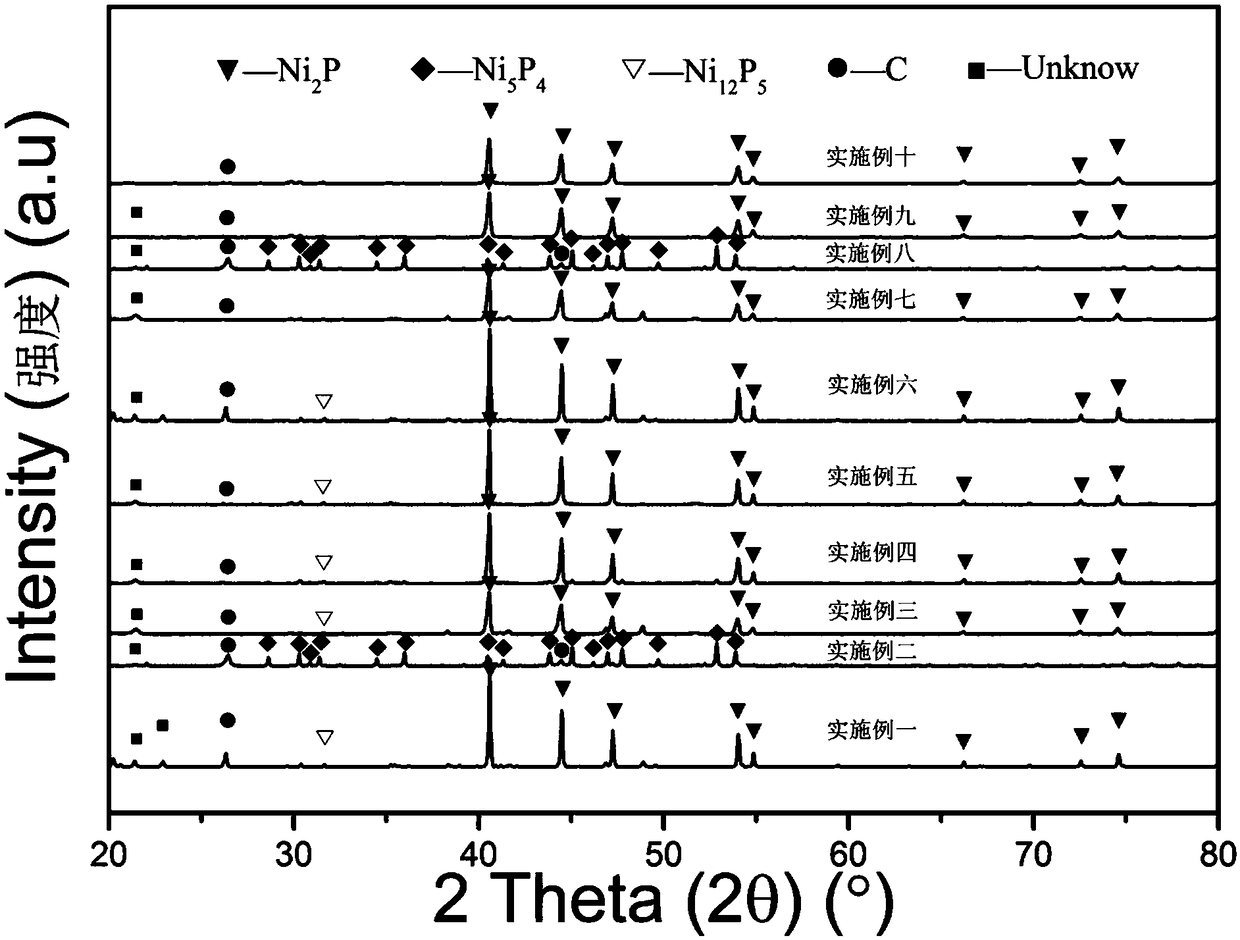

[0041] The prepared spherical metallic nickel powder was repeatedly washed and dried with distilled water, and the prepared spherical metallic nickel powder was sieved for microstructure analysis. The average particle size was selected to be 10 μm, and the average specific surface area was 61 μm. 2 / g, the spherical metallic nickel powder with an average pore size distribution of 30nm is used as the nickel reaction source, figure 1 It is a scanning electron micrograph of the prepared spherical metallic nickel powder, as shown in the figure, the spherical metallic nickel powder adopted in the present invention has high sphericity, uniform mesopores, and good molding rate. The obtained spherical metal nickel powder and the purchased red phosphorus are placed in an agate crucible according to the molar ratio Ni:P=0.2, and are ground evenly, then in the nickel-phosphorus mixture, adding a mass ratio of 3% graphene is mixed evenly, and then poured Put it into the mold of the tablet...

Embodiment 2

[0043] The prepared spherical nickel metal powder was repeatedly washed and dried with distilled water, and the average particle size was 30 μm, and the average specific surface area was 61 m 2 / g, the average pore size distribution is that the spherical metal nickel powder of 30nm and red phosphorus are mixed and ground uniformly according to the molar ratio Ni:P=0.3, then in this nickel-phosphorus mixture, adding mass ratio is 4% graphene and mixed uniformly, then carry out For tableting treatment, the pressure was 15MPa, and the storage time was 15s. The obtained tableted sample was placed in a vacuum drying oven with a vacuum degree of -0.1MPa, dried at 70°C for 1.2h, and then naturally cooled to room temperature. Place the compressed sample in the middle of a nitrogen atmosphere tube furnace, close the channel of the tube furnace and clean it with nitrogen for 20 minutes, then under the protection of argon, the argon flow rate is 10mL / min, the temperature is programmed to ...

Embodiment 3

[0045] The prepared spherical nickel metal powder was repeatedly washed and dried with distilled water, and the average particle size was 45 μm, and the average specific surface area was 68 m 2 / g, the average pore size distribution is that the spherical metal nickel powder of 30nm and the red phosphorus are mixed and ground according to the molar ratio Ni:P=0.5, then in this nickel-phosphorus mixture, adding mass ratio is 5% graphene and mixed evenly, then carry out For tableting treatment, the pressure was 18MPa, and the storage time was 20s. The obtained tableted sample was placed in a vacuum drying oven with a vacuum degree of -0.1MPa, dried at 80°C for 1.4h, and then naturally cooled to room temperature. Place the compressed sample in the middle of a nitrogen atmosphere tube furnace, close the channel of the tube furnace and clean it with nitrogen for 25 minutes, then under the protection of argon, the argon flow rate is 20mL / min, the temperature is programmed to 600 ° C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com